Product Description

Product Description

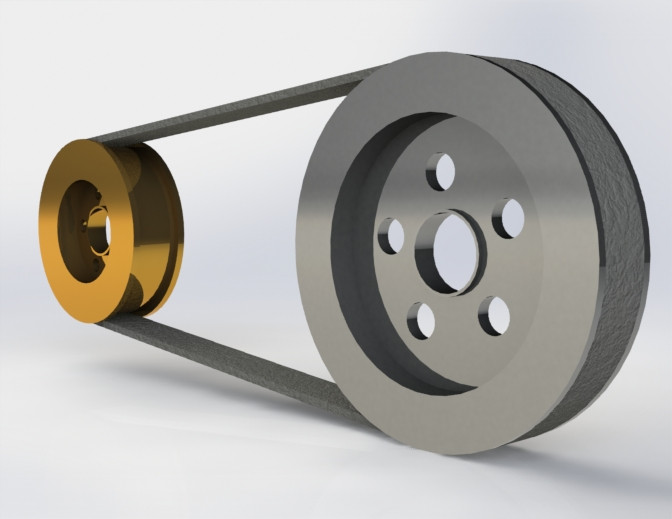

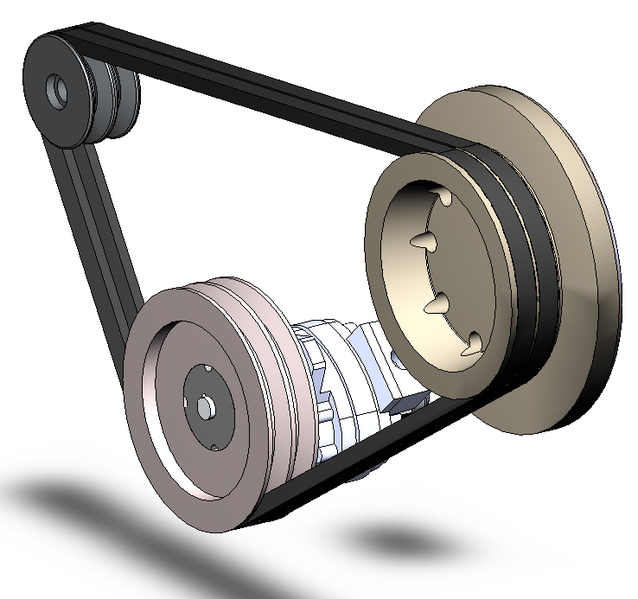

Material: 6061 aluminum alloy, S45C

Surface treatment: natural color anodized, blackened, galvanized

Model: MXL, XL, L, H, XH, XXH, T2.5, T5, T10, T20, AT5, AT10, AT20, 2M, 3M, 5M, 14M, S2M, S3M, S5M, S8M, S14M, 2GT, 3GT, 5GT, 8MGT, 14MGT, 8YU

We can produce according to your drawings.

Product Parameters

Packaging & Shipping

Our Advantages

1. We have over 10 years’ experience.

2. OEM or Non-Standard Bearings: any requirement for Non-standard bearings, timing pulleys are easily fulfilled by us due to our vast knowledge and links in the industry.

3. After Sales Service and Technical Assistance: Our company provides after-sales service and technical assistance as per the customer’s requirements and needs.

4. Quick Delivery: Our company provides just-in-time delivery with our streamlined supply chain.

5.We attend promptly to any customer questions. We believe that if our customers are satisfied then it proves our worth. Our customers are always given quick support.

Please contact us immediately if you have any questions.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Type A |

| Manufacturing Process: | Forging |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How are belt pulleys employed in agricultural machinery and equipment?

Belt pulleys play a crucial role in agricultural machinery and equipment, contributing to various functions and operations in the agricultural industry. They are used in a wide range of applications, from power transmission and driving different agricultural implements to controlling the speed and functionality of various systems. Here’s a detailed explanation of how belt pulleys are employed in agricultural machinery and equipment:

1. Power Transmission: Belt pulleys are extensively used for power transmission in agricultural machinery. They serve as the driving force to transfer power from the tractor’s power take-off (PTO) to different agricultural implements. The PTO pulley, connected to the tractor’s PTO shaft, drives the belt, which, in turn, drives the pulleys on the implements, such as mowers, balers, harvesters, and seeders. This power transmission enables the implements to perform their specific functions effectively.

2. Crop Harvesting and Processing: Belt pulleys are employed in various agricultural machinery involved in crop harvesting and processing. For example, in combine harvesters, belt pulleys are used to drive the cutting mechanism, threshing drum, and grain conveyors. The rotation of the pulleys enables the harvesting and separation of crops from the fields. In processing equipment like grain elevators and conveyors, belt pulleys facilitate the movement of harvested crops for storage or further processing.

3. Irrigation Systems: Belt pulleys are utilized in irrigation systems in agriculture. In irrigation pumps, belt pulleys connect the pump’s drive shaft to the power source, such as an electric motor or a tractor’s PTO. The rotation of the pulleys drives the pump, which boosts water pressure and facilitates irrigation by distributing water to crops through sprinklers, drip lines, or other irrigation methods.

4. Feed and Forage Processing: Belt pulleys are employed in machinery used for feed and forage processing in the agricultural industry. For instance, in feed mixers, belt pulleys drive the mixing auger or paddle mechanism, ensuring thorough blending of different feed ingredients. In forage choppers or silage harvesters, belt pulleys drive the cutting mechanism and the feed rollers, enabling the efficient harvesting and chopping of forage crops.

5. Livestock Equipment: Belt pulleys are used in various livestock equipment and machinery. In milking machines, belt pulleys drive the vacuum pump, creating suction for milking cows. Conveyor systems for livestock feed or manure management also employ belt pulleys to transport feed or handle manure efficiently. Additionally, in barn ventilation systems, belt pulleys drive the fans, facilitating air circulation and maintaining optimal environmental conditions for livestock.

6. Speed Control and Functionality: Belt pulleys are utilized to control the speed and functionality of different agricultural machinery. By using pulleys of varying sizes or adjusting the pulley arrangement, the speed of the driven implements or systems can be modified to suit specific agricultural operations. This allows for customization and adaptability in tasks such as soil cultivation, planting, spraying, and material handling.

7. Custom Applications: Belt pulleys are also employed in custom applications in agriculture, depending on specific requirements. Farmers and equipment manufacturers may design and incorporate belt pulleys in unique ways to drive specialized equipment, such as conveyor systems, grain cleaners, hay baling systems, or other agricultural machinery tailored to their specific needs.

In summary, belt pulleys have diverse applications in agricultural machinery and equipment. From power transmission and driving agricultural implements to controlling speed, facilitating crop harvesting and processing, supporting irrigation systems, and enabling functionality in various equipment, belt pulleys play a vital role in optimizing agricultural operations and enhancing productivity in the agricultural industry.

Can belt pulleys be customized for specific machinery and equipment?

Yes, belt pulleys can be customized to meet the specific requirements of machinery and equipment in various applications. Customization allows for the adaptation of belt pulleys to specific dimensions, performance characteristics, and operational needs. Here’s a detailed explanation of how belt pulleys can be customized for specific machinery and equipment:

1. Dimensional Customization: Belt pulleys can be customized to match the dimensional requirements of the machinery and equipment they will be installed in. This includes customizing the diameter, width, and groove dimensions of the pulleys to ensure proper fit and alignment with the system. Customization ensures that the belt pulleys integrate seamlessly into the machinery, optimizing performance and reliability.

2. Material Selection: Depending on the specific requirements of the machinery and equipment, belt pulleys can be customized with different materials. The choice of materials can be based on factors such as load capacity, environmental conditions, chemical resistance, and operating temperature. Common materials used for customized belt pulleys include steel, aluminum, cast iron, and various composites. Custom material selection ensures that the pulleys can withstand the demands of the application.

3. Specialized Coatings and Finishes: In certain applications, customized belt pulleys may require specialized coatings or finishes to enhance their performance. For example, pulleys used in food processing or pharmaceutical industries may require coatings that comply with specific safety and hygiene standards. Customized coatings can also provide corrosion resistance or reduce friction, improving the overall efficiency and longevity of the pulleys.

4. Groove Profiles: Belt pulleys can be customized with specific groove profiles to match the type of belt being used. Different belts, such as V-belts, timing belts, or flat belts, have varying groove requirements. Customizing the groove profiles ensures optimal belt engagement, maximizing power transmission efficiency and preventing belt slippage.

5. Special Features: In some cases, customized belt pulleys may require additional features or modifications to meet specific operational needs. This can include the incorporation of keyways, set screws, flanges, or other attachments to ensure proper alignment and secure mounting. Customized pulleys can also be designed with specific hub configurations or balancing requirements to achieve smooth and balanced operation in the machinery and equipment.

6. Performance Optimization: Customized belt pulleys can be tailored to optimize performance in specific applications. This may involve adjusting the pulley design, such as modifying the number of grooves or altering the pitch diameter, to achieve the desired speed ratios or torque requirements. Performance optimization ensures that the customized pulleys contribute to the efficient and reliable operation of the machinery and equipment.

Overall, belt pulleys can be customized to match the dimensional requirements, material specifications, coating needs, groove profiles, special features, and performance optimization of specific machinery and equipment. Customization ensures that the pulleys seamlessly integrate into the system, providing efficient power transmission and meeting the unique operational needs of the application.

How does a belt pulley function in power transmission?

A belt pulley plays a crucial role in power transmission by enabling the transfer of rotational motion and torque between rotating shafts. It functions as a mechanical device that connects the driving shaft to the driven shaft through a belt or a rope. The rotational motion of the driving shaft is transmitted to the driven shaft via the belt pulley, allowing power to be transferred from one shaft to another. Here’s a detailed explanation:

A belt pulley functions in power transmission through the following process:

- The driving shaft, which is typically connected to a motor or an engine, rotates and generates rotational motion and torque.

- The belt pulley is mounted on the driving shaft, and its grooved rim is designed to engage with a belt or a rope.

- A belt or a rope is wrapped around the groove of the belt pulley, creating a secure connection between the pulley and the belt.

- As the driving shaft rotates, the belt or rope, in contact with the grooved rim of the pulley, starts to move.

- The movement of the belt or rope causes the belt pulley to rotate.

- Since the belt pulley is connected to the driven shaft, which is the output shaft of the system, the rotational motion of the pulley is transferred to the driven shaft.

- Consequently, the driven shaft starts to rotate at the same speed and direction as the driving shaft.

- The rotational motion and torque generated by the driving shaft are effectively transmitted to the driven shaft through the belt pulley and the belt or rope.

It’s important to note that the design and configuration of the belt pulley, along with the belt or rope, are essential for efficient power transmission. The groove profile of the pulley should match the belt or rope profile to ensure proper engagement and prevent slippage. The tension in the belt or rope should be appropriately adjusted to maintain a secure connection between the pulley and the belt. Additionally, the size and ratio of the pulleys connected by the belt can be adjusted to control the speed and torque output, providing flexibility in power transmission.

In summary, a belt pulley functions in power transmission by connecting the driving shaft to the driven shaft through a belt or a rope. It transfers the rotational motion and torque generated by the driving shaft to the driven shaft, allowing power to be transmitted between the two shafts. The design, configuration, and tensioning of the belt and the pulley are crucial for efficient and reliable power transmission in mechanical systems.

editor by CX

2024-05-16