Product Description

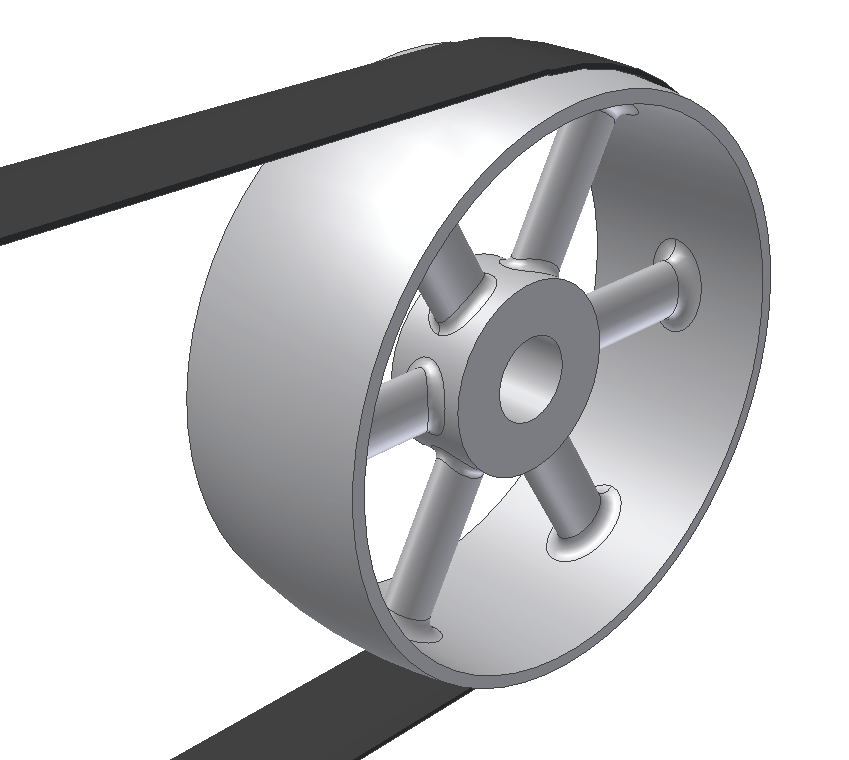

High Performance Pulley for Belt Conveyors

BRIEF INTRODUCTION

Our company has adopted proprietary technology and equipment imported from German PWH company for the design and manufacturing of various pulleys . As a key component of the conveyor, the pulley should have high reliability. Our company’s R&D center has improved the pulley structure, reduced structural stress, and increased the lifespan and reliability of the pulley group through finite element analysis and optimization calculations. Our company’s pulley is manufactured from specialized high-end manufacturing equipment and has achieved serialized and large-scale production.

We have produced conveyor pulleys for belt width up to 2.4 m, pulley diameter up to 1.8 m, and maximum tension up to 300 tons.

PRODUCT INFORMAITON

| Product Name | Pulley |

| Adhesive Material | smooth, ordinary rubber, wear-resistant rubber, UHMW-PE, rubber ceramic, etc.. |

| Adehensive Treatment | glued or casted |

| Carrying Capacity | light, medium and heavy type |

| Connection Mode | Shafts and wheels of the medium and heavy-duty pulley are connected by expansion sleeves. |

| Pulley Pipe | made of Q235B carbon steel, with high roundness and straightness ensuring rotation balance |

| Shaft | 45 # round steel or according to your requirements; ultrasonic inspection, quenching and tempering treatment, strict control of key fit size tolerances, greatly extending service life. |

| Bearing Brands | Havalo, SKF, FAG, SNK or according to your requirements |

| Bear Seat | Integral bearing seat, partial bearing seat |

| Color | bright red paint or according to your requirements |

VARIOUS TYPES OF PULLEY ADHESIVE SURFACE

BEARING SEAT MODE

TECHNICAL SPECIFICATIONS & PARAMETERS

| Technical Parameters for Belt Conveyor Pulley | ||||||

| Belt Width (mm) | Pulley Standard Diameter without Adhesive Layer(mm) | |||||

| 650 | 200,250,320,400,500,630 | |||||

| 800 | 200,250,320,400,500,630,800,1000,1250 | |||||

| 1000 | 250,320,400,500,630,800,1000,1250,1400,1600 | |||||

| 1200 | 250,320,400,500,630,800,1000,1250,1400,1600 | |||||

| 1400 | 320,400,500,630,800,1000,1250,1400,1600 | |||||

| 1600 | 400,500,630,800,1000,1250,1400,1600 | |||||

| 1800 | 250,400,500,630,800,1000,1250,1400,1600 | |||||

| 2000 | 400,500,630,800,1000,1250,1400,1600 | |||||

| Technical Parameters | ||

| 1 | Outer Circle Diameter D Deviation | 200 ≤ 1.5 400 ≤ 2.0 1000 ≤ 2.5 |

| 2 | Radial Runout of Outer Circle | D ≤ 200 ; without adhesive 0.3 ;with adhesive 0.5 200 < D ≤ 800 ; without adhesive 0.6; with adhesive 1.1 800 < D ≤ 1600 ; without adhesive 1.0; with adhesive 1.5 1600 < D ≤ 1800 ; without adhesive 1.5; with adhesive 2.0 |

| 3 | Static Balance Accuracy | G40 |

PROCESS FLOW OF PULLEY

Our company is equipped with necessary equipment for processing pulleys, such as large oil pressure machines, rolling machines, specialized pulley automatic explosive welding operators, large diameter lathes, boring machines, ultrasonic flaw detectors, static balancing devices, pressure casting machines, etc. Due to the special correction process adopted by the company, the pulley pipe skin is rounded before processing, and the pulley pipe wall is uniform after processing, thereby ensuring that the pulley has high static balance performance and high mechanical performance.

PRODUCT FEATURES

For pulleys with complex forces, large loads and used in heavy working conditions, they all adopt a cast welded structure and expansion sleeve connection. Compared with traditional drums in China, this type of drum mainly has the following characteristics :

(1) The structural parameters of the pulley are advanced and reasonable, and there is a dedicated computer calculation program to determine the shaft diameter, cylinder skin thickness, wheel amplitude plate shape and spacing, as well as the position of the circumferential weld seam set at the position where the stress is minimum and the number of cycles is minimum.

(2) The key technology of using single sided welding and double sided forming ensures the quality of the weld seam.

(3) The expansion sleeve connection is used between the drum hub and shaft, which not only solves the problem of key connection stress concentration that has been existing for many years and the technical difficulties of manufacturing and installing axial double keyways, but also achieves overall quenching and eliminates welding internal stress.

(4) The circumferential and longitudinal welds of the pulley have undergone non-destructive testing, and the casting quality of the wheel hub has undergone magnetic particle or ultrasonic testing.

(5) The total radial runout of the outer circle after roller casting is less than 1mm.

(6) All drums undergo static balance tests before leaving the factory to achieve G40 accuracy.

(7) All driving pulley and directional pulley with high stress have undergone finite element analysis to ensure that the stress and strain of the rollers meet the requirements.

Due to a series of measures taken, the pulley group produced by SK has a reasonable structure, large bearing capacity, and reliable performance. And it overcomes the problem of fatigue fracture at the welding seam of the existing pulley plate in China. The pullley (including the welding part) is guaranteed to have a rotational fatigue strength of over 108°.

WORKSHOP OF FINISHED PULLEIES

PACKAGE AND DELIVEYR

APPLICATION INDUSTRIES

CONVEYORS EPC/BOT CONTRACTING CAPABILITY

VARIOUS CONVEYOR SPARE PARTS SUPPLY

AERIAL VIEW OF OUR FACTORY

INTELLIGENT PRODUCTION & TESTING

CERTIFICATES & HORNORS

BRANCHES & OFFICES

TEAM BUILDING

LONG-TERM STRATEGIC COOPEATORS

MAIN CUSTOMERS

CUSTOMERS VISITS

DOMESTIC & OVERSEAS EXHIBITIONS

SINGING CEREMONY

GLOBAL BUSINESS NETWORK

B /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Kk |

| Manufacturing Process: | Forging, Casting |

| Material: | Carbon Steel |

| Surface Treatment: | Smooth, Rubber or Ceramics |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant, Port, Dock, Energy, Cement, Metallurgy, Steel |

| Samples: |

US$ 7/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can belt pulleys be part of HVAC systems and air conditioning units?

Yes, belt pulleys can indeed be part of HVAC (Heating, Ventilation, and Air Conditioning) systems and air conditioning units. They play a crucial role in the operation of these systems, contributing to the movement of air, power transmission, and controlling the functionality of various components. Here’s a detailed explanation of how belt pulleys are involved in HVAC systems and air conditioning units:

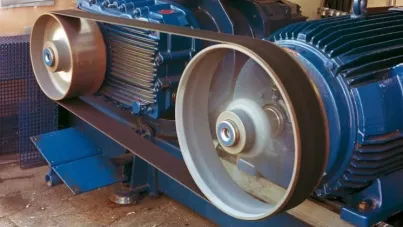

1. Air Handling Units: Belt pulleys are commonly used in air handling units (AHUs) of HVAC systems. AHUs are responsible for circulating and conditioning air within buildings. Belt-driven AHUs employ pulleys to drive the fans or blowers that move air through the system. The rotation of the pulleys drives the fan blades, creating airflow and facilitating the exchange of heat or coolness in the air conditioning process.

2. Cooling Towers: Cooling towers, a key component of HVAC systems, are used to remove heat from the building. Belt pulleys are employed in cooling towers to drive the fan systems that enhance the cooling process. The pulleys drive the cooling tower fans, which draw in ambient air and facilitate the evaporation of water, effectively dissipating heat and lowering the temperature of the circulated water.

3. Fan Coil Units: Fan coil units are part of HVAC systems and provide localized heating or cooling to specific areas within a building. Belt pulleys can be used in fan coil units to drive the fans that distribute conditioned air. The rotation of the pulleys drives the fan blades, enabling the movement of air through the unit and delivering heating or cooling to the desired space.

4. Compressors: In air conditioning units, belt pulleys are employed in the compressor system. The compressor is responsible for compressing the refrigerant, which enables the cooling process. Belt-driven compressors use pulleys to drive the compressor’s motor, which pressurizes the refrigerant and facilitates its movement through the air conditioning system. The pulleys ensure the efficient operation of the compressor, which is essential for the cooling function.

5. Power Transmission: Belt pulleys are essential for power transmission in HVAC systems and air conditioning units. They are used to transmit power from the motor or engine to various components, such as fans, compressors, pumps, and other mechanical parts. The rotation of the pulleys transfers power and enables the operation of these components, ensuring the functionality of the HVAC system or air conditioning unit.

6. Variable Speed Control: Belt pulleys can also be utilized for variable speed control in HVAC systems. By using pulleys of different sizes or incorporating variable speed pulley systems, the rotational speed of fans or other driven components can be adjusted. This allows for precise control over airflow, temperature, and overall system performance, optimizing energy efficiency and comfort levels in the building.

7. Maintenance and Serviceability: Belt pulleys in HVAC systems and air conditioning units are designed for easy maintenance and serviceability. They allow for straightforward belt replacement or adjustment, ensuring that the system can be properly maintained and serviced to maintain optimal performance and reliability.

In summary, belt pulleys are integral components of HVAC systems and air conditioning units. They are involved in power transmission, driving fans and blowers, controlling compressors, and facilitating the movement of air for heating, cooling, and ventilation. Belt pulleys contribute to the overall functionality, energy efficiency, and serviceability of HVAC systems, playing a vital role in providing comfortable and controlled environments in residential, commercial, and industrial buildings.

Can belt pulleys be customized for specific machinery and equipment?

Yes, belt pulleys can be customized to meet the specific requirements of machinery and equipment in various applications. Customization allows for the adaptation of belt pulleys to specific dimensions, performance characteristics, and operational needs. Here’s a detailed explanation of how belt pulleys can be customized for specific machinery and equipment:

1. Dimensional Customization: Belt pulleys can be customized to match the dimensional requirements of the machinery and equipment they will be installed in. This includes customizing the diameter, width, and groove dimensions of the pulleys to ensure proper fit and alignment with the system. Customization ensures that the belt pulleys integrate seamlessly into the machinery, optimizing performance and reliability.

2. Material Selection: Depending on the specific requirements of the machinery and equipment, belt pulleys can be customized with different materials. The choice of materials can be based on factors such as load capacity, environmental conditions, chemical resistance, and operating temperature. Common materials used for customized belt pulleys include steel, aluminum, cast iron, and various composites. Custom material selection ensures that the pulleys can withstand the demands of the application.

3. Specialized Coatings and Finishes: In certain applications, customized belt pulleys may require specialized coatings or finishes to enhance their performance. For example, pulleys used in food processing or pharmaceutical industries may require coatings that comply with specific safety and hygiene standards. Customized coatings can also provide corrosion resistance or reduce friction, improving the overall efficiency and longevity of the pulleys.

4. Groove Profiles: Belt pulleys can be customized with specific groove profiles to match the type of belt being used. Different belts, such as V-belts, timing belts, or flat belts, have varying groove requirements. Customizing the groove profiles ensures optimal belt engagement, maximizing power transmission efficiency and preventing belt slippage.

5. Special Features: In some cases, customized belt pulleys may require additional features or modifications to meet specific operational needs. This can include the incorporation of keyways, set screws, flanges, or other attachments to ensure proper alignment and secure mounting. Customized pulleys can also be designed with specific hub configurations or balancing requirements to achieve smooth and balanced operation in the machinery and equipment.

6. Performance Optimization: Customized belt pulleys can be tailored to optimize performance in specific applications. This may involve adjusting the pulley design, such as modifying the number of grooves or altering the pitch diameter, to achieve the desired speed ratios or torque requirements. Performance optimization ensures that the customized pulleys contribute to the efficient and reliable operation of the machinery and equipment.

Overall, belt pulleys can be customized to match the dimensional requirements, material specifications, coating needs, groove profiles, special features, and performance optimization of specific machinery and equipment. Customization ensures that the pulleys seamlessly integrate into the system, providing efficient power transmission and meeting the unique operational needs of the application.

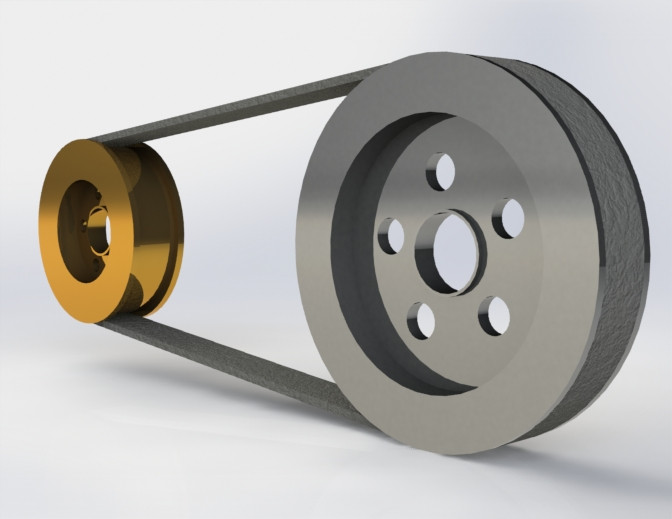

What is a belt pulley, and how is it used in mechanical systems?

A belt pulley is a mechanical device used in various systems to transmit power and motion between rotating shafts. It consists of a wheel with a grooved rim, known as the pulley, that is connected to a shaft. The pulley is typically made of materials such as cast iron, steel, or aluminum. It is used in conjunction with a belt or a rope to transfer rotational motion from one shaft to another. Here’s a detailed explanation:

A belt pulley is essential in mechanical systems for the following purposes:

- Power Transmission: The primary function of a belt pulley is to transmit power between rotating shafts. It connects the driving shaft (input) to the driven shaft (output) through a belt or a rope. When the driving shaft rotates, the belt or rope engages with the grooves on the pulley, causing the pulley and the driven shaft to rotate. This allows power to be transferred from the driving shaft to the driven shaft, enabling the operation of various mechanical components or systems.

- Speed Control: Belt pulleys are used to control the rotational speed of driven shafts. By varying the size or ratio of the pulleys connected by the belt, the rotational speed can be adjusted. Using different-sized pulleys, it is possible to increase or decrease the speed of the driven shaft compared to the driving shaft. This speed control capability is beneficial in applications where different rotational speeds are required for specific operations or to match the requirements of different components in a system.

- Directional Change: Belt pulleys also enable the change of direction in mechanical systems. By arranging multiple pulleys with belts or ropes in a system, the rotational motion can be redirected. For example, a system with two pulleys connected by a belt can change the direction of the driven shaft compared to the driving shaft. This directional change allows for the transmission of power and motion in desired orientations, enabling the operation of mechanical components or systems in different directions.

- Tension Control: Belt pulleys play a role in maintaining proper tension in belt-driven systems. The tension in the belt is important to ensure a secure and reliable connection between the pulleys. Pulleys with adjustable features, such as tensioning systems or idler pulleys, help maintain the optimal tension in the belt. Proper tension control prevents belt slippage, ensures efficient power transmission, and reduces wear on the belt and pulley surfaces.

- Noise and Vibration Reduction: Belt pulleys contribute to noise and vibration reduction in mechanical systems. The design of the pulley, including the groove profile and surface finish, can help minimize noise and vibration generated during operation. Additionally, proper alignment and tensioning of the belt ensure smoother engagement with the pulley, reducing noise and vibration levels. This is particularly important in applications that require quiet operation or where excessive vibrations can affect system performance or operator comfort.

- Compatibility and Interchangeability: Belt pulleys offer compatibility and interchangeability benefits in mechanical systems. They provide a flexible and modular approach to power transmission, allowing different pulleys to be easily interchanged or replaced based on specific requirements. This versatility enables system designers and operators to adapt and modify mechanical systems more efficiently, making it easier to accommodate changes in load, speed, or other operational parameters.

In summary, a belt pulley is a mechanical device used for power transmission and motion control in various mechanical systems. It connects rotating shafts through belts or ropes, allowing power to be transmitted from one shaft to another. Belt pulleys provide speed control, directional change, tension control, noise and vibration reduction, as well as compatibility and interchangeability benefits. By utilizing belt pulleys, mechanical systems can efficiently transfer power, control speeds, and enable the operation of different components or systems in desired directions.

editor by CX

2024-05-17