Product Description

Chain Pulley Gearbox Wood Garden Wall Crankshaft Plant Km Series Belt Flat Taper Lock Cable Machine Tensioner PRO Fitness Attachment System Arm Tricep Suppliers

Application of Chain Pulley

Chain pulleys are a type of pulley that uses a chain instead of a rope or cable. They are typically used in applications where a high lifting capacity is required, such as in construction and manufacturing.

Chain pulleys work by using the chain to wrap around a wheel or drum. When you pull on the chain, it turns the wheel or drum, which in turn lifts the load. Chain pulleys can be used to lift heavy loads with less effort than if you were to lift them manually.

Chain pulleys are available in a variety of sizes and capacities. The size of the pulley will depend on the weight of the load that you need to lift. The capacity of the pulley will depend on the amount of force that you can apply to the chain.

Chain pulleys are a versatile tool that can be used in a variety of applications. They are typically used in construction and manufacturing, but they can also be used in other applications, such as:

- Agriculture

- Mining

- Logistics

- Warehousing

- Marine

Chain pulleys are a safe and reliable way to lift heavy loads. They are easy to use and maintain, and they can be used in a variety of applications.

Here are some of the advantages of using a chain pulley:

- High lifting capacity. Chain pulleys can lift heavy loads with less effort than if you were to lift them manually.

- Durability. Chain pulleys are made from high-quality materials that can withstand heavy use.

- Versatility. Chain pulleys can be used in a variety of applications.

- Ease of use. Chain pulleys are easy to use and maintain.

If you are looking for a way to lift heavy loads with less effort, then a chain pulley is a great option.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

How do flat belt pulleys affect the performance of textile manufacturing machinery?

Flat belt pulleys have a significant impact on the performance of textile manufacturing machinery. Here’s a detailed explanation:

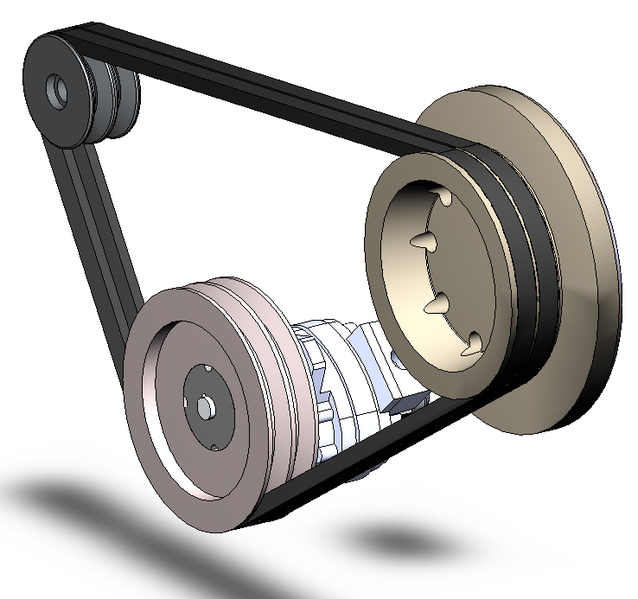

1. Power Transmission:

Flat belt pulleys are essential for transmitting power from the motor or engine to various components within textile manufacturing machinery. They serve as driving pulleys, connecting the power source to critical machine parts, such as spindles, rollers, and looms. The efficient power transmission facilitated by flat belt pulleys ensures the smooth operation of these components, enabling the production of high-quality textiles.

2. Speed Control:

Textile manufacturing machinery often requires precise speed control for different processes, such as spinning, weaving, or knitting. Flat belt pulleys, when used in conjunction with adjustable speed drives, allow operators to control the rotational speed of the driven components. By selecting pulleys of different sizes or adjusting the pulley positions, the speed ratios can be modified, enabling optimal machine performance and ensuring the production of textiles with consistent quality.

3. Tensioning and Tracking:

Flat belts in textile manufacturing machinery need to be properly tensioned and tracked to ensure smooth and reliable operation. Flat belt pulleys are equipped with tensioning mechanisms and tracking features to maintain the appropriate belt tension and alignment. Proper tensioning and tracking, facilitated by the pulleys, prevent belt slippage, reduce wear and tear, and minimize the occurrence of defects in textile production.

4. Belt Longevity:

Flat belt pulleys, when designed and maintained correctly, contribute to the longevity of the belts used in textile manufacturing machinery. The pulleys should have smooth surfaces and edges, minimizing friction and wear on the belts. Additionally, regular inspection and maintenance of the pulleys, including checking for proper alignment and cleaning, help prevent belt damage and extend their lifespan.

5. Noise and Vibration Reduction:

Textile manufacturing machinery often operates at high speeds, leading to noise and vibration. Properly balanced and aligned flat belt pulleys help reduce these undesirable effects by ensuring smooth and stable power transmission. Minimizing noise and vibration improves the working environment for operators and helps maintain the integrity of the textile manufacturing process.

6. Maintenance and Replacement:

Flat belt pulleys in textile manufacturing machinery are relatively easy to maintain and replace. Regular inspection and lubrication of the pulleys, along with routine belt tension checks, contribute to efficient operation and prevent unexpected breakdowns. When replacement is necessary, flat belts and pulleys are readily available, minimizing downtime and optimizing overall machine performance.

7. Cost-effectiveness:

Flat belt pulleys offer a cost-effective solution for power transmission in textile manufacturing machinery. They are relatively simple in design, require minimal maintenance, and have lower initial costs compared to alternative transmission systems. The cost-effectiveness of flat belt pulleys makes them a preferred choice in the textile industry.

Overall, flat belt pulleys play a vital role in textile manufacturing machinery by ensuring efficient power transmission, enabling speed control, maintaining belt tension and tracking, enhancing belt longevity, reducing noise and vibration, facilitating maintenance and replacement, and providing a cost-effective solution. Their proper selection, installation, and maintenance are crucial for optimal performance and productivity in textile manufacturing processes.

What types of materials are commonly used for flat belt pulley components?

Flat belt pulleys are typically composed of various materials for different components to meet specific requirements. Here’s a detailed explanation:

1. Pulley Body:

The main body of a flat belt pulley is commonly made of durable and rigid materials such as:

- Steel: Steel pulleys offer excellent strength, durability, and resistance to wear. They are commonly used in heavy-duty applications where high load capacities and long service life are required.

- Cast Iron: Cast iron pulleys are known for their high strength and resistance to wear. They are often used in industrial applications where durability and reliability are essential.

- Aluminum: Aluminum pulleys are lightweight and have good corrosion resistance. They are commonly used in applications where weight reduction is a priority or in environments where corrosion is a concern.

- Plastics: Certain types of plastics, such as nylon or polyurethane, are used in pulleys where low weight, noise reduction, or chemical resistance is required. Plastic pulleys are often used in applications that involve delicate or sensitive machinery.

2. Hub:

The hub of a flat belt pulley, which connects the pulley to the shaft, is typically made of:

- Steel: Steel hubs offer high strength and reliable connection to the shaft. They are commonly used in heavy-duty applications.

- Aluminum: Aluminum hubs are lightweight and provide good corrosion resistance. They are often used in applications where weight reduction is important.

3. Surface Coating:

To enhance the performance and durability of flat belt pulleys, surface coatings or treatments may be applied. Some common coatings include:

- Zinc or Nickel Plating: These coatings provide corrosion resistance and improve the pulley’s appearance.

- Anodizing: Anodized coatings on aluminum pulleys increase their resistance to wear and corrosion.

- Powder Coating: Powder coating provides a durable and protective layer on the pulley surface, offering improved aesthetics and resistance to corrosion, chemicals, and abrasion.

It’s important to select the appropriate materials for flat belt pulleys based on factors such as the application’s load requirements, environmental conditions, desired lifespan, and cost considerations. Consulting with pulley manufacturers or suppliers can help in determining the most suitable materials for specific pulley components.

How do flat belt pulleys differ from other types of pulleys?

Flat belt pulleys have distinct characteristics that set them apart from other types of pulleys. Here’s a detailed explanation:

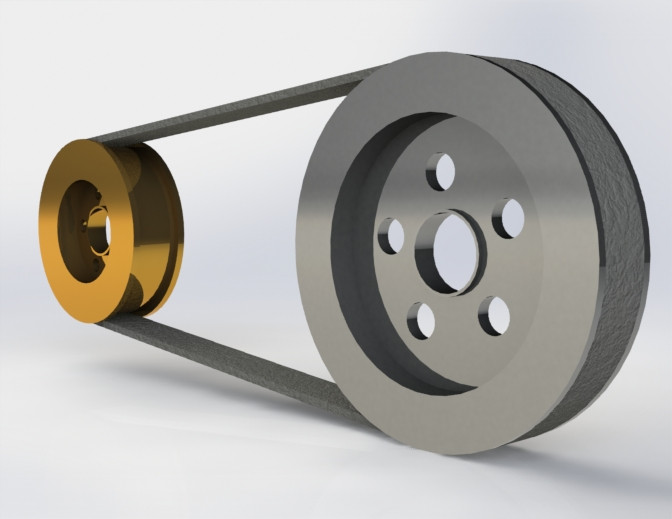

1. Belt Type:

The major difference lies in the type of belt used. Flat belt pulleys are specifically designed to work with flat belts, which are flexible and have a rectangular cross-section. In contrast, other types of pulleys, such as V-belt pulleys or timing belt pulleys, are designed for different belt profiles, such as V-shaped belts or toothed belts.

2. Belt Engagement:

Flat belt pulleys engage with the belt differently compared to other pulley types. The flat belt wraps around the pulley’s flat or slightly concave surface and relies on friction to transmit power. Other pulley types, like V-belt pulleys, have grooves that match the shape of the belt, providing positive engagement by fitting into the belt’s grooves.

3. Power Transmission:

Each pulley type is optimized for specific power transmission requirements. Flat belt pulleys are often used for applications that require relatively low power and moderate speeds. They are suitable for machinery that needs flexibility and ease of installation, making them commonly used in older machinery and certain industrial applications. Other pulley types, like V-belt pulleys or timing belt pulleys, offer advantages for high-power transmission, increased efficiency, or precise timing in applications such as automotive engines or industrial machinery.

4. Pulley Design:

Flat belt pulleys have a simple design, typically consisting of a cylindrical or disk-shaped body with a flat or slightly concave surface. Other pulley types may have more complex designs to accommodate specific belt profiles. For example, V-belt pulleys have grooves that match the V-shaped belts, while timing belt pulleys have toothed profiles that match the teeth on the timing belts.

5. Speed and Torque Conversion:

The design and configuration of pulleys, including flat belt pulleys, allow for speed and torque conversion. By varying the sizes of the pulleys, the speed and torque can be adjusted to meet the requirements of the machinery. However, the specific mechanisms for speed and torque conversion may differ between pulley types. For example, V-belt pulleys rely on the varying diameters of the pulleys to achieve speed conversion, while timing belt pulleys use the toothed profiles to ensure precise timing and synchronization.

6. Belt Tension and Alignment:

The methods used to maintain belt tension and alignment can also differ between pulley types. Flat belt pulleys often rely on adjustable pulley positions or tensioning mechanisms to achieve proper tension and alignment. Other pulley types may incorporate features like automatic tensioners or specialized tensioning systems to maintain optimal belt performance.

In conclusion, flat belt pulleys differ from other types of pulleys in terms of the belt type, engagement method, power transmission capabilities, design, speed and torque conversion mechanisms, as well as belt tension and alignment methods. Understanding these differences is crucial for selecting the appropriate pulley type for a given application.

editor by CX

2024-05-06