Product Description

We can produce conveyor rollers of various standards, diameters, lengths, and types

Welcome to write to us

Product Description

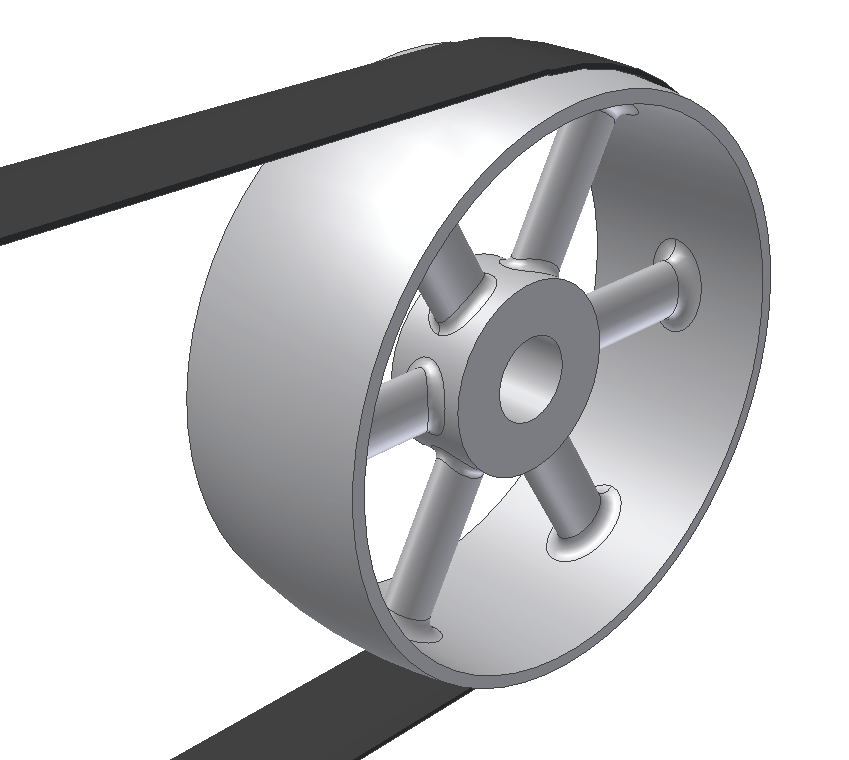

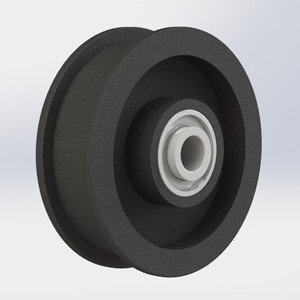

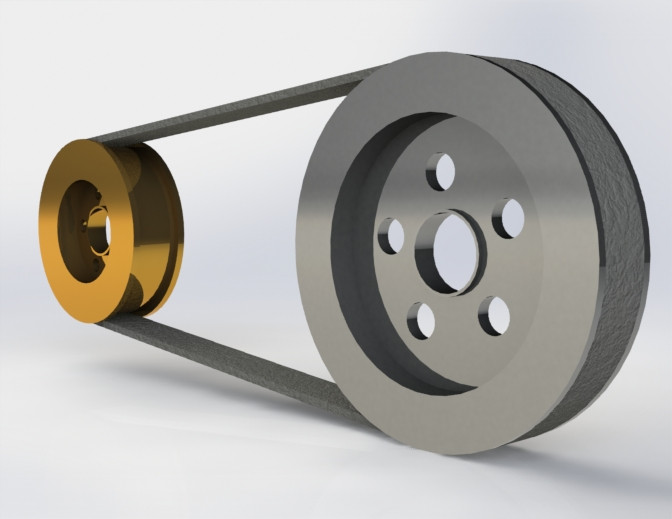

| Description | Fabrication Services flat belt idler pulley for belt conveyor |

| Application | Used in electric power, metallurgy,mine,coal, cement,steel,chemical, port, hydroelectric power and grain industries |

| Pipe/Tube/Shell | 1)Material:Q235 Steel 2)Diameter:219mm-3000mm 3)Length:500mm-5000mm,depends on the belt width of the conveyor |

| Shaft/Axis | Material:#45 Steel |

| Bearing | Big roving crack, deep groove ball with double sealing |

| Welding | Pipe and bearing housing with automatic welding |

| Surface | Smooth steel color surface, rubber lagging surface |

| Color | Red,green,blue or as require |

| Service life | More than 30,000 hours |

| Standard | GB,ISO,DIN,CEMA,JIS |

Our Pulley Features:

| Conveyor Pulley Test | 1. All butt welds shall be full Penetration 2. All welds to be full seal welds to prevent rust 3. Shell seam welds are submerged arc (SAW) 4. Includes stress relieving of shell prior to machining 5. Ultrasonic testing of all shafts 6. Drillings for Temperature probe / vibration analysis device 7. Remove all butts and sharp edges |

| Conveyor Pulley Shaft Selection | The major cause of conveyor pulley failure is excessive shaft deflection. The Conveyor Pulleys – ZheJiang HSCD Engineering department can perform Stress Analysis and Finite Element Analysis to maximize your conveyor pulley performance. |

| Conveyor Pulley Shell Material | Q345B Carbon Steel GR350 Carbon Steel ANSI 4140 Alloy Steel ASTM A514B Stainless Steel |

| Bearing House | SKF/NSK/ /HRB/LYC, as customer request. |

| Conveyor Pulley Lagging | Plain rubber lagging, Herringbone and CHINAMFG grooves are all available . Hot Vulcanised Durometer . Hardness 50-55-65 Shore A, M Grade . Oil Resistant, Heat Resistant FRAS |

| Comprising | •Drive pulley, Head pulley and Tail Pulleys •Take-Up Pulleys, •Snub pulley & Bend Pulleys •Self Cleaning Spiral CHINAMFG pulley & Drum Pulleys |

| Significant advantages | • The thick pulley shell absorbs more stress. • The large CHINAMFG angle provides superior belt tracking capabilities. • True concentric machining provides: • maximum contact with the belt, • consistent belt content discharge, • less deflection of shaft, • less stress on the bearings |

| Available Conveyor Pulley Designs |

•Liveshaft or Deadshaft types. •Flat or crowned shell. •Taconite, labyrinth or speciality seals. •Oil or grease lubricated. •Self centering or low pressure lock element designs. |

Our workshop

Our packaging

our products

Our certificate

Packaging & Shipping

Company Profile

ITALY CHINAMFG OU GROUP is a CHINAMFG international companies in the world advanced level . REAL is a registered trademark of CHINAMFG OU GROUP , designed and manufactured REAL brand roller, roller , large belt conveyors in Italy, Germany, Turkey and other countries have extensive influence , by customers alike. CHINAMFG OU GROUP valued Chinese market there is huge potential, has been dedicated to the development of China ‘s roller market. In order to meet the needs of the customers , after many visits screening, HangZhou CHINAMFG Conveying Machinery Co.,Ltd, advanced production technology and years of quality customers as a platform , has won REAL directors unanimously approved, CHINAMFG OU GROUP authorized HangZhou CHINAMFG Conveying Machinery Co.,Ltd REAL brand for the Chinese region specified design and development, production and sales, service as 1 of the company, CHINAMFG OU GROUP, with its strong technical foundation, rich belt conveyor production experience and the international influence of the brand as a backup support, REALwith CHINAMFG joint venture together to open up the Chinese market a variety of mine roller, belt conveyors businesses together to provide our customers with quality services. HangZhou CHINAMFG Conveying Machinery Co.,Ltd was founded in May 2 thousand and five. It’s a private enterprise of stock-holding system .It was located in the economic and technological development zone of Xihu (West Lake) Dis. town, HangZhou city. ZheJiang province .This place is beautiful and CHINAMFG ,and the transport is very convenient.On November 18, 2013, joint venture with the ITALY CHINAMFG OU GROUP, specializes in producing REAL brand TD75, DTII, DTIIA type fixed conveyor, mobile elevating conveyors, roller and roller.The products have gained various patents . We have got the national industrial products production license issued by the state administration of quality supervision, inspection and quarantine of the People’s Republic of China , the company has been identified as CHINAMFG trademarks in dHangZhou city committee. Enhance the brand of ‘YI LUN’.Our company has the right of exportation and the products are sold to Middle East ,Africa ,Australia ,Europe ,Southeast Asia ,Russia and some other countries and regions. The company has large lathe, numerical control, double pressing machine, double welding machine, double boring lathe, milling machine, sawing machine and so on .The company produces more than 2 thousand rollers a day and over 7 hundred thousand a year .We choose and use the special tube ,cold-drawing shaft and famous bearing to make the rollers ,and the rollers were sealed by nylon .The professional inspectors used testing equipments to examine waterproof , preventing static electricity ,sideways ,moving up and down ,revolving resistance and falling of the rollers .The examine result is that the qualified rate of the rollers is over 98%. The noise of the rollers is very low and its turning is very nimble .The life of the rollers is over 30000 hours ,and the products were praised by all the customers .The products were widely used for mine ,coal mine ,port ,steel plant ,electric plant ,feed-processing plant ,cement plant and some other enterprises. This company pursues that credit is as aim and puts the quality above all else .We request to live and develop with quality and credit .Strengthen the inner management and improve the quality of the products constantly .Offer the best products for customers from the beginning to the end .At the same time ,provide quality service for the customers ,because serving the customers well is also the aim of our enterprise.

| HangZhou CHINAMFG Conveying Co., Ltd | |

| Name | roller,idler,pulley |

| Material | Stainless Steelseamless pipe, welded pipe |

| Size | Any size as your demand |

| Color | Red, yellow,any color as your demand |

| Standard | ISO 9001:2000 , BV Certificate |

| MOQ | 10-50 pcs |

| Bearing | 6204,6205,6206,6305 ect |

| Shaft diameter | 20-40 mm |

| Pipe diameter | 60-219 mm |

| Type | DT75,DTII,DTIIA,TK,TKII |

| OEM | Welcome |

| Lifetime | At least 5000 hours |

| Material for transport | Coal,Ore,Clinker,grain,plant,fertilizer,ect |

| Paint | Common paint and baking varnish |

| Producing capacity | 1500pcs per day |

| Payment Term | TT, L/C |

| Loading port | ZheJiang ,HangZhou |

| Production Time | 7-15days after getting the deposite |

| Specifications | 1.Large capacity,2.High speed.3.Easy to install,repaire and maintenance.4.High output,efficiency,low noise. |

| Advantage | 1.Best price.2.Quality control whole process.3.Quick,efficient,comprehensive service. |

FAQ

1. who are we?

We are based in ZheJiang , China, start from 2005,sell to Mid East(64.00%),Eastern Asia(16.00%),South America(7.00%),Southeast Asia(7.00%),Africa(6.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Alway

s final Inspection before shipment;

3.what can you buy from us?

Belt Conveyor,Conveyor Spare Parts,Conveyor Pulley,roller brackets,belts

4. why should you buy from us not from other suppliers?

We have a professional team with rich experience in conveyor industry at CHINAMFG Our team will provide first-class service to you.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,FCA,Express Delivery;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Russian /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Surface Treatment: | Polishing |

| Motor Type: | Frequency Control Motor |

| Installation: | Turning |

| Thickness of Rubber Surface: | 8mm 10mm 12mm 15mm 20mm |

| Diameter: | 159—2000mm |

| Customization: |

Available

| Customized Request |

|---|

How are belt pulleys utilized in the production of electronics and semiconductors?

In the production of electronics and semiconductors, belt pulleys play a crucial role in various manufacturing processes. They are utilized in different stages of production to facilitate precision, efficiency, and reliability. Here’s a detailed explanation of how belt pulleys are utilized in the production of electronics and semiconductors:

1. Conveyor Systems: Belt pulleys are commonly used in conveyor systems within electronics and semiconductor manufacturing facilities. These conveyor systems transport components, products, or wafers between different stages of production, such as assembly, testing, and packaging. Belt pulleys are utilized to drive the conveyor belts, ensuring smooth and controlled movement of the materials or products. They contribute to the efficient flow of production, allowing for continuous and automated handling of electronic components and semiconductor wafers.

2. Wafer Handling: Belt pulley systems are employed in the handling and processing of semiconductor wafers. These wafers, which serve as the base material for electronic devices, need to be transferred between various equipment and processing stations. Belt pulleys, along with precision belts, are used to grip and transport the delicate and flat wafers. The pulleys ensure accurate positioning and controlled movement of the wafers, essential for precise alignment during processes such as etching, deposition, and lithography.

3. Robotics and Automation: Belt pulleys are integral components in robotics and automation systems utilized in electronics and semiconductor production. These systems often involve robotic arms or gantries that handle and manipulate components or equipment. Belt pulleys are employed in the motorization and control mechanisms of these robotic systems, enabling precise and repeatable movements. They contribute to the accuracy, speed, and reliability required in tasks such as pick-and-place operations, soldering, and inspection processes.

4. Precision Machining: Belt pulleys are used in precision machining operations within electronics and semiconductor production. They are incorporated into milling machines, lathes, and other machining equipment that fabricate electronic components and semiconductor parts. Belt pulleys drive the cutting tools or spindles, providing the necessary rotational motion for precise material removal and shaping. The speed control and torque conversion capabilities of belt pulleys ensure the optimal performance and accuracy required for manufacturing intricate electronic and semiconductor components.

5. Testing and Inspection Equipment: Belt pulleys are utilized in testing and inspection equipment within the electronics and semiconductor industry. These machines perform various tests, measurements, and inspections to ensure the quality and functionality of electronic components and semiconductor devices. Belt pulleys drive the mechanisms that move the components or devices through different testing or inspection stations. They contribute to the controlled and synchronized movement required for accurate measurements, functional tests, and quality checks.

6. Packaging and Labeling: Belt pulleys are employed in packaging and labeling systems for electronics and semiconductor products. These systems handle the final packaging of electronic components, devices, or integrated circuits. Belt pulleys drive the conveyor belts that transport the packaged products, ensuring their smooth and efficient movement through the packaging and labeling processes. They contribute to the automated and streamlined packaging operations, allowing for high-speed production and consistent product presentation.

7. Maintenance and Serviceability: Belt pulleys contribute to the maintenance and serviceability of equipment used in electronics and semiconductor production. They are designed for easy replacement, adjustment, or inspection, allowing for quick and straightforward maintenance tasks. Properly maintained belt pulleys ensure the reliability and uptime of production equipment, minimizing downtime and optimizing the overall manufacturing process.

In summary, belt pulleys are utilized in the production of electronics and semiconductors for conveyor systems, wafer handling, robotics and automation, precision machining, testing and inspection equipment, packaging and labeling systems, as well as maintenance and serviceability. They contribute to the efficient flow of production, precise positioning of components, accurate machining, reliable testing and inspection, streamlined packaging, and ease of equipment maintenance. Belt pulleys play a vital role in enhancing the precision, efficiency, and reliability of the manufacturing processes involved in electronics and semiconductor production.

Can belt pulleys be customized for specific machinery and equipment?

Yes, belt pulleys can be customized to meet the specific requirements of machinery and equipment in various applications. Customization allows for the adaptation of belt pulleys to specific dimensions, performance characteristics, and operational needs. Here’s a detailed explanation of how belt pulleys can be customized for specific machinery and equipment:

1. Dimensional Customization: Belt pulleys can be customized to match the dimensional requirements of the machinery and equipment they will be installed in. This includes customizing the diameter, width, and groove dimensions of the pulleys to ensure proper fit and alignment with the system. Customization ensures that the belt pulleys integrate seamlessly into the machinery, optimizing performance and reliability.

2. Material Selection: Depending on the specific requirements of the machinery and equipment, belt pulleys can be customized with different materials. The choice of materials can be based on factors such as load capacity, environmental conditions, chemical resistance, and operating temperature. Common materials used for customized belt pulleys include steel, aluminum, cast iron, and various composites. Custom material selection ensures that the pulleys can withstand the demands of the application.

3. Specialized Coatings and Finishes: In certain applications, customized belt pulleys may require specialized coatings or finishes to enhance their performance. For example, pulleys used in food processing or pharmaceutical industries may require coatings that comply with specific safety and hygiene standards. Customized coatings can also provide corrosion resistance or reduce friction, improving the overall efficiency and longevity of the pulleys.

4. Groove Profiles: Belt pulleys can be customized with specific groove profiles to match the type of belt being used. Different belts, such as V-belts, timing belts, or flat belts, have varying groove requirements. Customizing the groove profiles ensures optimal belt engagement, maximizing power transmission efficiency and preventing belt slippage.

5. Special Features: In some cases, customized belt pulleys may require additional features or modifications to meet specific operational needs. This can include the incorporation of keyways, set screws, flanges, or other attachments to ensure proper alignment and secure mounting. Customized pulleys can also be designed with specific hub configurations or balancing requirements to achieve smooth and balanced operation in the machinery and equipment.

6. Performance Optimization: Customized belt pulleys can be tailored to optimize performance in specific applications. This may involve adjusting the pulley design, such as modifying the number of grooves or altering the pitch diameter, to achieve the desired speed ratios or torque requirements. Performance optimization ensures that the customized pulleys contribute to the efficient and reliable operation of the machinery and equipment.

Overall, belt pulleys can be customized to match the dimensional requirements, material specifications, coating needs, groove profiles, special features, and performance optimization of specific machinery and equipment. Customization ensures that the pulleys seamlessly integrate into the system, providing efficient power transmission and meeting the unique operational needs of the application.

Can you explain the different types of belt pulleys and their applications?

There are several different types of belt pulleys, each designed for specific applications and requirements. The choice of pulley type depends on factors such as the power transmission needs, speed control requirements, space limitations, and the type of belt or rope used. Here’s an overview of some common types of belt pulleys and their applications:

1. V-Belt Pulleys: V-belt pulleys are one of the most widely used types of pulleys. They have a trapezoidal groove profile and are designed to accommodate V-belts, which have a corresponding cross-sectional shape. V-belt pulleys are commonly used in applications that require high torque transmission, such as in industrial machinery, automotive engines, and HVAC systems.

2. Flat Belt Pulleys: Flat belt pulleys have a flat or slightly crowned surface without any grooves. They are used with flat belts, which have a rectangular cross-section. Flat belt pulleys are suitable for applications that require high-speed power transmission, such as in textile machines, printing presses, and conveyor systems.

3. Timing Belt Pulleys: Timing belt pulleys, also known as synchronous pulleys, have teeth or grooves that mesh with the teeth of a timing belt. This design provides precise and synchronous power transmission, making them suitable for applications that require accurate positioning and timing, such as in robotics, CNC machines, and automotive engines.

4. Variable Speed Pulleys: Variable speed pulleys, also called adjustable or variable pitch pulleys, allow for continuous speed control by adjusting the effective diameter of the pulley. They feature movable pulley halves or arms that change the distance between the grooves, altering the speed ratio. Variable speed pulleys are used in applications where adjustable speed control is required, such as in machinery with variable loads or in variable speed drives.

5. Step Pulleys: Step pulleys have multiple grooves of different diameters arranged on the same pulley. By changing the belt position between these different grooves, the speed ratio can be adjusted. Step pulleys are commonly used in machines such as drill presses, lathes, and milling machines, where a range of predetermined speeds is required for different operations.

6. Idler Pulleys: Idler pulleys are not directly involved in power transmission but are used to redirect and tension the belt. They help maintain proper belt tension, improve belt wrap around the pulleys, and assist in achieving the desired belt path. Idler pulleys are commonly used in automotive engines, HVAC systems, and other belt-driven systems.

7. Clutch Pulleys: Clutch pulleys are specialized pulleys that incorporate a clutch mechanism. They allow for on-demand engagement and disengagement of the pulley from the driven shaft. Clutch pulleys are commonly used in automotive applications, such as in alternators, where they enable efficient power generation while reducing drag during idle or deceleration.

It’s important to note that these are just a few examples of belt pulley types, and there may be other specialized designs based on specific application requirements. The selection of the appropriate belt pulley type depends on factors such as the power transmission needs, speed control requirements, load capacity, and the type of belt or rope used.

In summary, different types of belt pulleys, such as V-belt pulleys, flat belt pulleys, timing belt pulleys, variable speed pulleys, step pulleys, idler pulleys, and clutch pulleys, are designed for specific applications and requirements. Understanding the characteristics and applications of these pulley types allows for the proper selection and utilization of belt pulleys in various mechanical systems.

editor by CX

2024-02-05