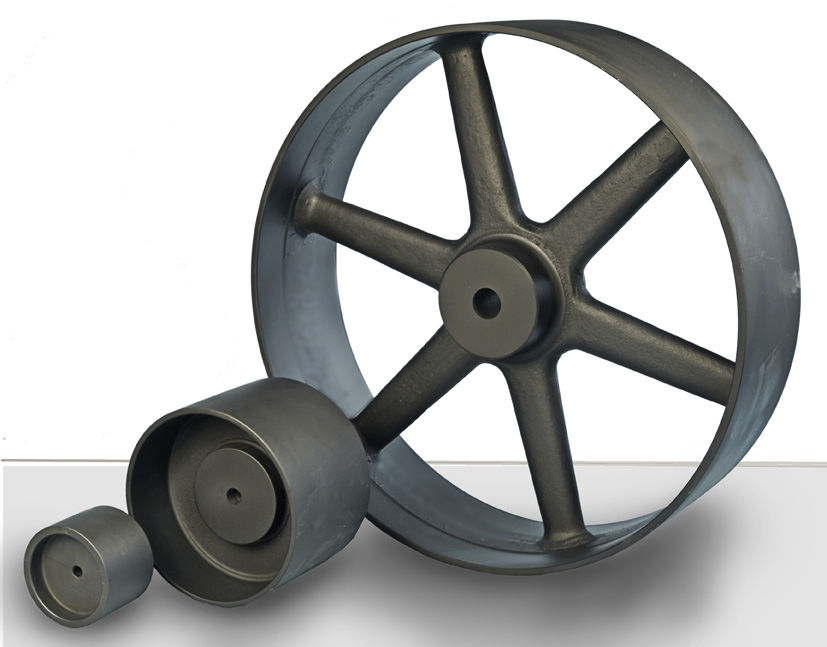

Product Description

multiple pulleys stainless steel flat mount nylon pulley v belt wheels flat wire rope sheave aluminum bearing Oversized Ceramic Electromagnetic Clutch Metal

Application of multiple pulleys

Multiple pulleys are a type of simple machine that can be used to lift heavy objects or to change the direction of a force. When multiple pulleys are used together, they can be used to increase the mechanical advantage of the system.

The mechanical advantage of a pulley system is the ratio of the force that is applied to the system to the force that is required to lift the load. For example, a system with 2 pulleys has a mechanical advantage of 2. This means that if you apply 100 pounds of force to the system, the load will be lifted with a force of 200 pounds.

Multiple pulleys are used in a variety of applications, including:

- Cranes: Cranes use multiple pulleys to lift heavy objects.

- Winches: Winches use multiple pulleys to pull or lift objects.

- Flagpoles: Flagpoles use multiple pulleys to raise and lower flags.

- Sails: Sails use multiple pulleys to control the direction of a boat.

- Lifts: Lifts use multiple pulleys to move people and objects between floors.

- Elevators: Elevators use multiple pulleys to move people and objects between floors.

- Bicycles: Bicycles use multiple pulleys to change the gears and to brake.

- Sewing machines: Sewing machines use multiple pulleys to move the needle and the fabric.

- Welding machines: Welding machines use multiple pulleys to move the welding torch.

- Grinders: Grinders use multiple pulleys to move the grinding wheel.

Multiple pulleys are a versatile and reliable type of simple machine that can be used in a variety of applications. They are easy to use and maintain, and they can help to make work easier and safer.

Here are some of the benefits of using multiple pulleys:

- They can increase the mechanical advantage of a system.

- They can be used to lift heavy objects.

- They can be used to change the direction of a force.

- They are easy to use and maintain.

- They can help to make work easier and safer.

If you are looking for a way to lift heavy objects or to change the direction of a force, a multiple pulley system is a great option.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Can flat belt pulleys be integrated into conveyor systems for material handling?

Yes, flat belt pulleys can be effectively integrated into conveyor systems for material handling. Here’s a detailed explanation:

Conveyor systems are widely used in industries for the efficient movement of materials from one location to another. Flat belt pulleys offer several advantages when incorporated into conveyor systems:

1. Power Transmission:

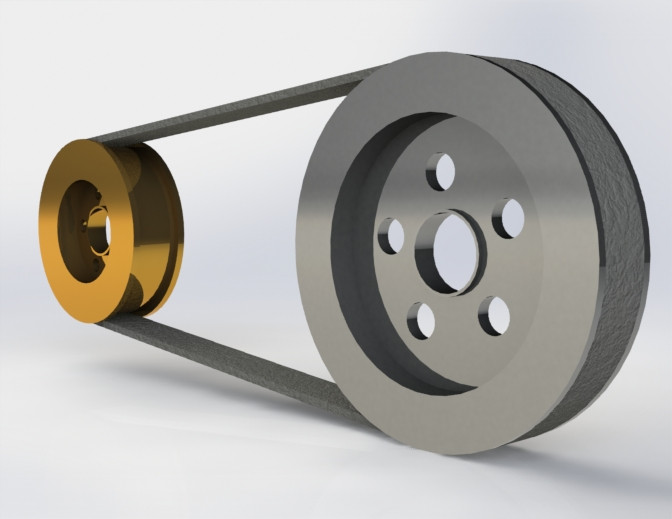

Flat belt pulleys are used as the driving pulleys in conveyor systems. They transmit power from a motor or an engine to the belt, enabling the movement of materials along the conveyor. The large contact area and grip between the pulleys and the belt ensure efficient power transfer, allowing for the transportation of various types of materials.

2. Load Capacity:

Flat belt pulleys are designed to handle different load capacities. They can be selected based on the specific requirements of the conveyor system, such as the weight and type of materials being transported. The pulley’s diameter and width are chosen to provide adequate support and load-bearing capacity for the belt.

3. Belt Tracking:

Proper belt tracking is crucial in conveyor systems to prevent belt misalignment and ensure smooth operation. Flat belt pulleys are designed with features such as flanges or guides to help keep the belt centered and aligned. This ensures that the materials are conveyed along the desired path without any disruptions or spillage.

4. Belt Tensioning and Adjustability:

Flat belt pulleys in conveyor systems are equipped with tensioning mechanisms to maintain the appropriate belt tension. These mechanisms, such as idler pulleys or tensioning screws, allow for easy adjustment of the belt tension to accommodate variations in load or belt stretch over time. Proper tensioning ensures efficient power transmission and prevents belt slippage.

5. Versatility:

Flat belt pulleys offer versatility in conveyor system design. They can be used in straight conveyors, curved conveyors, or inclined conveyors, allowing for the transportation of materials in various directions and angles. The flexibility of flat belts also enables efficient movement around pulleys of different sizes and configurations.

6. Maintenance and Replacement:

Flat belt pulleys in conveyor systems are relatively easy to maintain and replace. Regular inspection and maintenance of the pulleys, including checking for proper alignment and tension, can help prevent issues and ensure efficient operation. When replacement is necessary, flat belts and pulleys are readily available, minimizing downtime and optimizing material handling efficiency.

Consequently, flat belt pulleys are commonly integrated into conveyor systems for material handling due to their efficient power transmission, load capacity, versatility, and ease of maintenance. They are widely used in industries such as manufacturing, warehousing, mining, agriculture, and logistics.

Can flat belt pulleys be customized for specific machinery and equipment?

Yes, flat belt pulleys can be customized to suit specific machinery and equipment requirements. Here’s a detailed explanation:

1. Pulley Dimensions:

Flat belt pulleys can be customized in terms of their dimensions to fit the specific space and clearance constraints of the machinery or equipment. The outer diameter, inner diameter, and width of the pulley can be adjusted to ensure proper alignment and fit within the system.

2. Shaft Compatibility:

Customized flat belt pulleys can be designed to match the shaft size and configuration of the machinery or equipment. This ensures a secure and accurate connection between the pulley and the shaft, minimizing any potential slippage or misalignment issues.

3. Material Selection:

The choice of material for the pulley can be customized based on the specific requirements of the machinery or equipment. Different materials, such as steel, aluminum, or plastic, offer varying levels of strength, durability, and corrosion resistance. The material selection can be tailored to suit factors such as the operating environment, load capacity, and desired longevity of the pulley.

4. Keyways and Set Screw Holes:

Customized flat belt pulleys can be manufactured with keyways or set screw holes to enhance the connection and torque transfer between the pulley and the shaft. Keyways provide a positive locking mechanism, preventing rotational slippage, while set screw holes allow for secure fastening using set screws.

5. Surface Coatings:

In certain cases, customized flat belt pulleys can be coated or treated with specific surface finishes or coatings. These coatings can provide benefits such as improved wear resistance, reduced friction, or enhanced corrosion protection, depending on the operating conditions and requirements of the machinery or equipment.

6. Special Features:

Customized flat belt pulleys can incorporate special features or modifications based on the unique needs of the machinery or equipment. This may include additional mounting holes, balancing adjustments, or specific groove profiles to accommodate different belt types or configurations.

By working with pulley manufacturers or suppliers, machinery or equipment manufacturers can collaborate to design and produce customized flat belt pulleys that precisely meet the requirements of their specific applications.

It’s important to note that the customization process will depend on factors such as the complexity of the pulley design, production feasibility, and any minimum order quantities that may be required by the manufacturer.

In which industries are flat belt pulleys commonly used?

Flat belt pulleys are commonly utilized in various industries where power transmission using flat belts is required. Here’s a detailed explanation:

1. Manufacturing Industry:

The manufacturing industry extensively uses flat belt pulleys in various applications. They are employed in machinery for processes such as material handling, assembly lines, packaging, and cutting operations. Flat belt pulleys enable power transmission to drive conveyor belts, rollers, robotic arms, and other components, facilitating the movement, manipulation, and processing of materials in manufacturing facilities.

2. Textile Industry:

In the textile industry, flat belt pulleys play a crucial role in powering machinery used in textile manufacturing processes. They are used in equipment such as spinning machines, weaving looms, knitting machines, and textile printing machines. These pulleys transmit power to drive spindles, loom mechanisms, rollers, and printing cylinders, enabling efficient production of textiles.

3. Woodworking Industry:

Flat belt pulleys find wide application in the woodworking industry. They are used in various woodworking machinery such as table saws, band saws, planers, jointers, and sanders. Flat belt pulleys power components like blades, cutter heads, feeders, and sanding drums, allowing for precise cutting, shaping, and finishing of wood materials.

4. Packaging Industry:

In the packaging industry, flat belt pulleys are commonly used in packaging machinery. They transmit power to drive components like conveyor belts, rotary tables, fillers, and labelers. Flat belt pulleys enable smooth and efficient packaging processes, such as sorting, filling, sealing, and labeling of products.

5. Agricultural Industry:

Flat belt pulleys have applications in the agricultural industry, particularly in equipment used for crop processing and handling. They are used in machinery such as threshers, combines, grain elevators, and feed processing equipment. Flat belt pulleys power components like augers, conveyors, fans, and pumps, facilitating operations such as harvesting, grain transportation, and feed processing.

6. Printing Industry:

The printing industry utilizes flat belt pulleys in printing presses and other printing machinery. These pulleys transmit power to drive the printing cylinders, paper feeders, and other moving parts, ensuring precise paper movement and ink application during the printing process.

7. Automotive Industry:

In certain applications within the automotive industry, flat belt pulleys can be found. They may be used in specialized machinery or equipment for tasks such as engine testing, component manufacturing, or assembly line operations.

8. Other Industries:

Flat belt pulleys can also be found in other industries such as mining, food processing, paper mills, construction, and power generation. They are used in specific equipment or machinery where flat belt power transmission offers advantages such as simplicity, cost-effectiveness, and compatibility with existing systems.

It’s important to note that while flat belt pulleys continue to be used in various industries, advancements in technology have led to the adoption of alternative power transmission systems, such as V-belts, timing belts, or direct drives, in many applications.

editor by CX

2024-04-12