Product Description

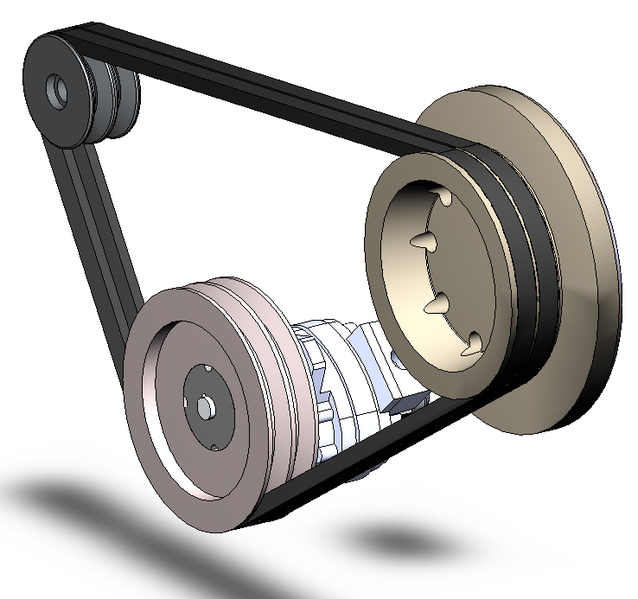

Grooved Sheave Wheel Aluminum Plastic Taper Lock Bush Idler Flat Poly V belt Adjustable Crankshaft Alternator Tension Agricultural Synchronous Timing Pulley

Timing pulley

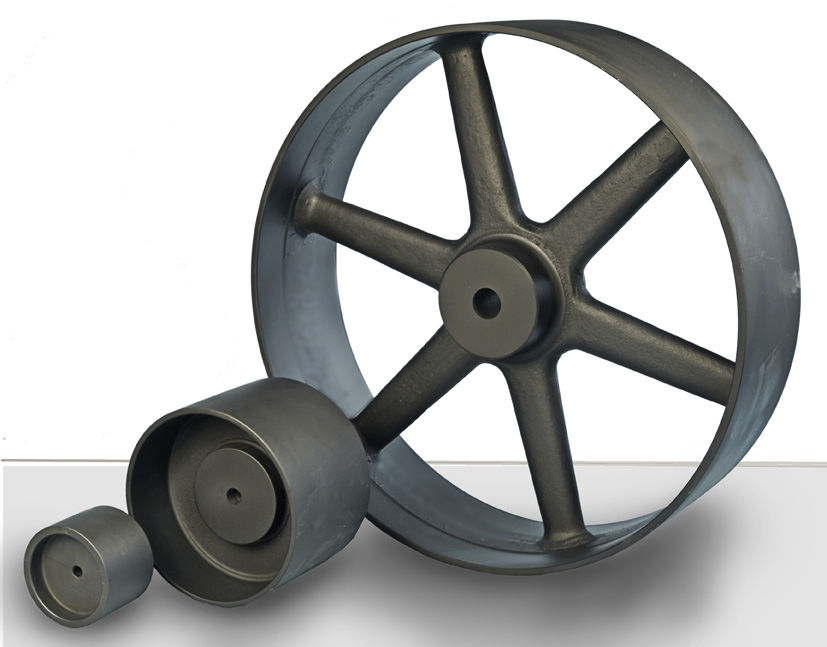

V- belt pulley

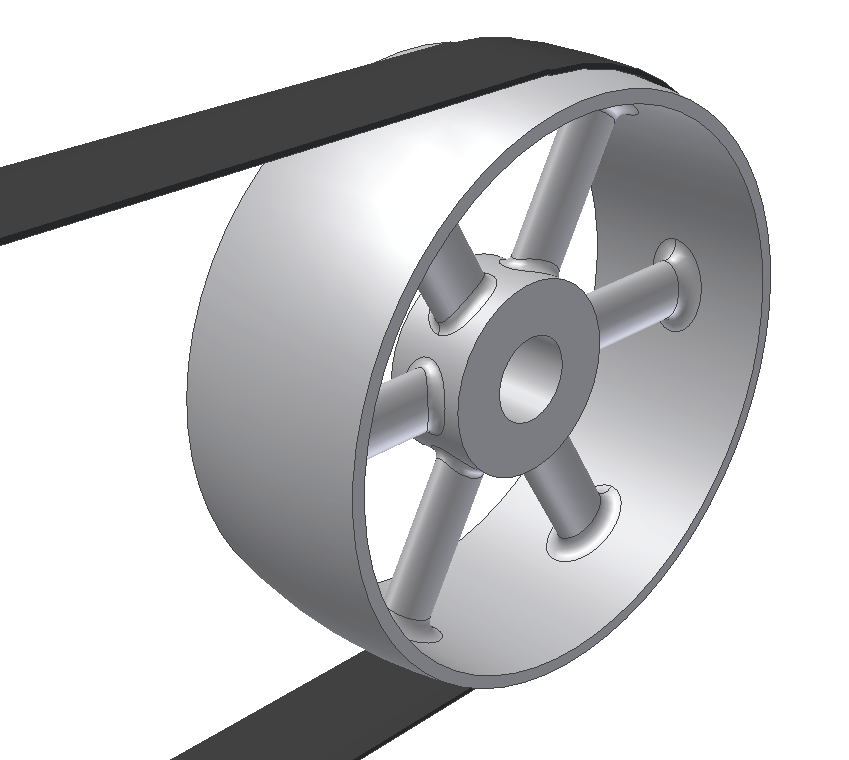

V- belt pulley of different types ( according to type and width of belts). The material used is cast iron EN-GJL-250 CHINAMFG EN 1561, and for only a few types it is steel C45 E CHINAMFG EN 10083-1. They have a small prebore that can be machined according to customers’ requirements. Moreover the most common types are available also with taperlock bore.

V belt pulley specifications

·

European standards :

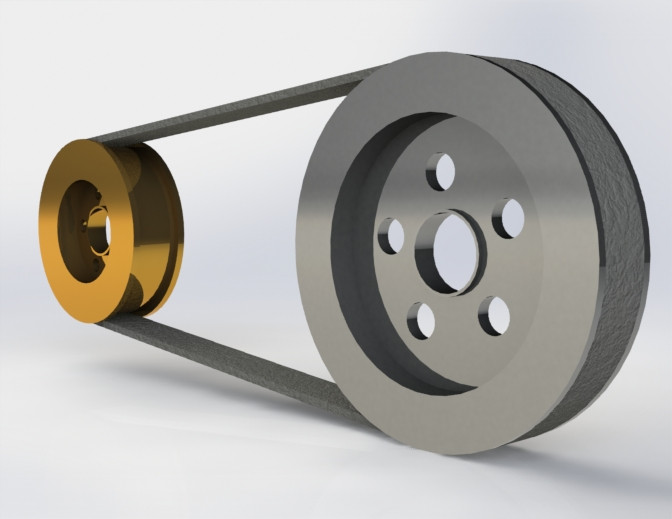

a) V-belt pulley for taper bushing: SPZ, SPA, SPB, SPC, up to 10 grooves

b) Adjustable speed V-belt pulleys and variable speed pulleys

c) Flat belt pulleys and conveyor belt pulleys

· American standard:

a) Sheaves for taper bushing: 3V, 5V, 8V

b) Sheaves for QD bushings: 3V, 5V, 8V

c) Sheaves for split taper bushing: 3V, 5V, 8V

d) Sheaves for 3L, 4L or A, and 5L or B belts: AK, AKH,2AK, 2AKH, BK, BKH,2BK, 2BKH, 3BK

e) Adjustable sheaves: poly V-pulley, multi-pitch H, L, J, K and M

· Bore: pilot bore, finish bore, taper bore, bore for QD bushing

– Parts can be made according to drawings and/or samples

· we can offer the rang size diameter 62MM~2000MM

Agricultural pulleys

If the belt pulley of your agricultural machinery is damaged or aged, you can buy a perfectly matched replacement here. Our belt pulley can adapt to the following brands:jo hn dee re, ca se-IH, Kub ota, welger, MTZ…

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type A |

| Manufacturing Process: | Casting |

| Material: | Iron |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Standards: | European American Standards |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

What is the role of flat belt pulleys in agricultural machinery and equipment?

Flat belt pulleys play a crucial role in agricultural machinery and equipment, contributing to various operations and functions. Here’s a detailed explanation:

1. Power Transmission:

Flat belt pulleys are commonly used in agricultural machinery to transmit power from an engine or motor to different components. They serve as driving pulleys, connecting the power source to various agricultural implements and equipment such as threshers, pumps, conveyors, and grain elevators. The efficient power transmission facilitated by flat belt pulleys enables the proper operation of these agricultural machines.

2. Belt-Driven Systems:

Many agricultural machines utilize belt-driven systems, where flat belts and pulleys are employed to transfer power. These systems are cost-effective, easy to maintain, and provide smooth power transmission. Flat belt pulleys are key components in these systems, ensuring reliable power transfer and facilitating the movement of materials or the operation of specific agricultural processes.

3. Threshing and Harvesting:

In agricultural machinery such as threshers, flat belt pulleys are integral to the threshing and harvesting process. They drive the rotating mechanisms that separate grain or seeds from the crop plants. The pulleys provide the necessary power to rotate the threshing drum or cylinder, facilitating the separation of grain or seeds from the harvested crop.

4. Irrigation and Water Pumps:

Flat belt pulleys are utilized in agricultural equipment for irrigation and water pumping applications. They drive water pumps that draw water from wells, rivers, or other sources and distribute it for irrigation purposes. The pulleys transmit power from the engine or motor to the pump, enabling efficient water pumping and irrigation operations in agricultural fields.

5. Conveyor Systems:

Agricultural conveyor systems, used for tasks such as transporting crops, seeds, or harvested produce, often incorporate flat belt pulleys. The pulleys drive the conveyor belts, facilitating the movement of agricultural materials within the farm or processing facility. These conveyor systems are crucial for efficient material handling and sorting in agricultural operations.

6. Equipment Adjustability:

Flat belt pulleys offer adjustability in agricultural machinery and equipment. By using pulleys of different sizes or adjusting the pulley positions, the speed ratios and power transmission characteristics can be modified. This adjustability allows farmers and operators to optimize the performance of agricultural machines based on specific requirements, crop conditions, or operational preferences.

7. Versatility and Durability:

Agricultural environments can be demanding, with exposure to dust, moisture, and other challenging conditions. Flat belt pulleys are designed to be versatile and durable, capable of withstanding the rigors of agricultural applications. They are often constructed from materials such as cast iron or steel, ensuring longevity and reliable performance even in harsh agricultural settings.

Overall, flat belt pulleys play a vital role in agricultural machinery and equipment by facilitating efficient power transmission, driving essential components and processes, enabling adjustability, and ensuring the smooth operation of various agricultural operations.

What safety considerations should be kept in mind when working with flat belt pulleys?

Working with flat belt pulleys involves certain safety considerations to prevent accidents and ensure safe operation. Here’s a detailed explanation:

1. Machine Guarding:

It is important to ensure that flat belt pulleys are properly guarded to prevent accidental contact with rotating parts. Guards should be in place to cover the pulley and belt, minimizing the risk of entanglement or entrapment of clothing, body parts, or tools.

2. Lockout/Tagout Procedures:

Prior to performing any maintenance or servicing tasks on machinery equipped with flat belt pulleys, proper lockout/tagout procedures should be followed. This involves isolating the power source, locking out the equipment, and clearly tagging it to indicate that maintenance work is in progress. This helps to prevent inadvertent startup of the machinery, which could cause serious injuries.

3. Personal Protective Equipment (PPE):

When working with flat belt pulleys, appropriate Personal Protective Equipment (PPE) should be worn. This may include safety glasses or goggles to protect the eyes from debris or flying particles, gloves to protect hands from sharp edges or pinch points, and hearing protection if the machinery generates excessive noise.

4. Training and Education:

Operators and maintenance personnel should receive proper training and education on the safe operation and maintenance of machinery with flat belt pulleys. They should be familiar with the potential hazards associated with these systems and understand the correct procedures for installation, tensioning, and adjustment of the belts.

5. Regular Inspections and Maintenance:

Flat belt pulleys should be regularly inspected for signs of wear, damage, or misalignment. Any issues should be addressed promptly to prevent further damage or potential accidents. Routine maintenance, including belt replacement, lubrication, and tension adjustments, should be performed according to the manufacturer’s recommendations.

6. Handling Heavy Loads:

When working with machinery that utilizes flat belt pulleys for heavy load transmission, proper lifting techniques should be employed to prevent strains or injuries. Mechanical lifting aids or equipment should be used as necessary to safely handle heavy loads.

7. Risk Assessment:

A thorough risk assessment should be conducted to identify and mitigate potential hazards associated with flat belt pulleys. This includes evaluating the layout of the machinery, the positioning of pulleys and belts, and any other factors that may pose a risk to the safety of operators or maintenance personnel.

By adhering to these safety considerations, the risk of accidents or injuries when working with flat belt pulleys can be significantly reduced. It is essential to follow industry best practices, manufacturer’s guidelines, and applicable safety regulations to ensure the safe operation of machinery equipped with flat belt pulleys.

Can you explain the typical applications of flat belt pulleys in machinery?

Flat belt pulleys are utilized in various machinery applications where power transmission using flat belts is required. Here’s a detailed explanation of their typical applications:

1. Industrial Machinery:

Flat belt pulleys find extensive use in industrial machinery across different sectors. They are commonly employed in machinery such as conveyor systems, manufacturing equipment, packaging machines, textile machinery, and woodworking machinery. These pulleys enable power transmission to drive various components, such as rollers, gears, cutting tools, and conveyor belts, facilitating the processing, movement, and manipulation of materials in industrial processes.

2. Agricultural Equipment:

In the agricultural sector, flat belt pulleys are used in machinery like threshers, combines, grain elevators, and hay balers. They play a crucial role in powering components such as fans, augers, pumps, and feeders. Flat belt pulleys provide a cost-effective and reliable solution for power transmission in agricultural equipment, allowing for efficient crop processing, harvesting, and handling operations.

3. Vintage Machinery:

Flat belt pulleys have historical significance and are often associated with vintage machinery. Before the widespread adoption of modern power transmission systems, such as V-belts or chains, flat belts and flat belt pulleys were commonly used. Therefore, flat belt pulleys can be found in antique or vintage machinery, including old lathes, milling machines, printing presses, and other early industrial equipment.

4. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems utilize flat belt pulleys in certain applications. These pulleys are used to transmit power to components like fans, blowers, and pumps in HVAC units. They help in ensuring efficient air circulation, temperature control, and fluid movement within HVAC systems, contributing to the overall performance and functionality of the systems.

5. Exercise Equipment:

Flat belt pulleys are also employed in exercise equipment such as treadmills, rowing machines, and stationary bikes. These pulleys assist in transferring power from the motor to the various moving parts of the exercise equipment, allowing for smooth and controlled movements during workouts.

6. Garage Door Openers:

Flat belt pulleys are used in garage door opener systems to transmit power from the motor to the pulley on the garage door shaft. The rotational motion of the pulley is transferred to the door’s lifting mechanism, enabling the smooth and automatic opening and closing of garage doors.

7. Other Applications:

Flat belt pulleys can be found in a range of other applications, including printing machines, paper mills, sewing machines, power tools, and various mechanical systems that require power transmission using flat belts.

It’s important to note that with advancements in technology, other types of power transmission systems, such as V-belts, timing belts, or direct drives, have gained popularity in many applications. However, flat belt pulleys continue to be used in specific machinery and industries where they offer advantages such as simplicity, cost-effectiveness, and compatibility with existing equipment.

editor by CX

2024-05-16