Product Description

Essential details

Condition:

New

Warranty:

6 Months

Shape:

Spur

Applicable Industries:

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Home Use, Retail, Construction works , Energy & Mining

Showroom Location:

None

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

New Product 2571

Warranty of core components:

6 Months

Core Components:

Gear

Place of Origin:

HangZhou, China

Brand Name:

OEM/DOP

Material:

Steel

Application:

Transmission Parts

Tooth Profile:

Super Gear

Size:

8M-20T

Material Standard:

Ductile Iron

Processing:

CNC Machining

Surface treatment:

As customer request

Heat treatment:

High Frequency Induction Hardening

Quality:

100% Inspection

Standard:

DIN ANSI ISO

Keyword:

helical ring gear

After Warranty Service:

Online support

Local Service Location:

None

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Casting Method: | Special Casting |

|---|---|

| Casting Form Material: | Metal |

| Casting Metal: | Cast Iron |

| Casting Form Usage Count: | Semi-permanent |

| Surface Treatment: | Power Coat |

| Surface Roughness: | Ra0.8 |

| Samples: |

US$ 2.0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What is the importance of proper pulley alignment and tensioning in belt pulley systems?

Proper pulley alignment and tensioning are of utmost importance in belt pulley systems. They directly impact the efficiency, reliability, and longevity of the system. Here’s a detailed explanation of the importance of proper pulley alignment and tensioning:

1. Power Transmission Efficiency: Proper pulley alignment and tensioning ensure efficient power transmission in belt pulley systems. Misaligned pulleys or incorrect belt tension can lead to slippage, which results in power loss. When the belts slip on the pulleys, the intended power transfer from the driving pulley to the driven pulley is compromised. By aligning the pulleys correctly and maintaining proper tension, the belts grip the pulleys securely, allowing for efficient power transmission and maximizing the system’s overall efficiency.

2. Prevents Belt Wear and Damage: Improper pulley alignment and tensioning can cause excessive belt wear and damage. Misaligned pulleys can cause the belts to run at an angle, resulting in uneven wear on the belt’s edges. This can lead to premature belt failure and the need for frequent belt replacements. Insufficient or excessive belt tension can also cause accelerated wear, as it puts additional strain on the belts. Proper alignment and tensioning help distribute the load evenly across the belts, minimizing wear and extending their lifespan.

3. Reduces Noise and Vibration: Correct pulley alignment and tensioning contribute to reducing noise and vibration in belt pulley systems. Misaligned pulleys can cause the belts to vibrate and generate noise during operation. Excessive belt tension can lead to increased vibration as well. These vibrations and noise not only affect the comfort of operators but can also impact the overall stability and performance of the system. Proper alignment and tensioning help minimize vibration and noise levels, creating a smoother and quieter operation.

4. Improves System Reliability: Proper pulley alignment and tensioning enhance the reliability of belt pulley systems. Misalignment or improper tension can lead to unexpected belt failures, system downtime, and costly repairs. When the belts slip or wear unevenly, it can cause disruptions in power transmission, resulting in reduced system performance or complete failure. Proper alignment and tensioning minimize the risk of belt-related issues, ensuring the system operates reliably and consistently.

5. Enhances Component Life: Correct pulley alignment and tensioning contribute to the longevity of system components. When the belts run smoothly and grip the pulleys properly, it reduces stress on the pulleys, bearings, and other mechanical parts. Misalignment or excessive tension can cause unnecessary strain on these components, leading to premature wear and failure. Proper alignment and tensioning help distribute the load evenly, minimizing stress and extending the life of system components.

6. Facilitates Easy Maintenance: Proper pulley alignment and tensioning make maintenance tasks easier. When pulleys are aligned correctly, it simplifies belt replacement, adjustment, or inspection procedures. Easy access to the belts and pulleys allows for efficient maintenance and reduces downtime during servicing. Additionally, proper tensioning ensures that belts can be adjusted or replaced without difficulty, improving overall serviceability of the system.

7. Optimizes System Performance: Ultimately, proper pulley alignment and tensioning optimize the performance of belt pulley systems. When the belts are aligned correctly and tensioned properly, the power transmission is efficient, wear is minimized, and vibrations are reduced. This results in reliable and consistent system operation, allowing the system to perform at its intended level of efficiency and productivity.

In summary, proper pulley alignment and tensioning are essential for efficient power transmission, prevention of belt wear and damage, reduction of noise and vibration, and improvement of system reliability. They enhance the lifespan of system components, facilitate maintenance tasks, and optimize the overall performance of belt pulley systems. By ensuring correct alignment and tension, operators can maximize the efficiency, reliability, and longevity of their belt pulley systems.

Can belt pulleys be used in both simple and complex mechanical systems?

Yes, belt pulleys can be used in both simple and complex mechanical systems. Belt pulleys are versatile components that are widely employed in various applications across different industries. They offer several advantages, such as reliable power transmission, flexibility in speed adjustment, and ease of installation. Here’s a detailed explanation of how belt pulleys can be utilized in both simple and complex mechanical systems:

1. Simple Mechanical Systems: Belt pulleys are commonly used in simple mechanical systems where power needs to be transmitted between two shafts. These systems typically involve straightforward power transmission requirements and relatively uncomplicated machinery. Examples of simple mechanical systems where belt pulleys are utilized include small appliances like fans or blenders, exercise equipment, and simple conveyor systems. In these cases, belt pulleys provide an efficient and cost-effective solution for transmitting power from a motor or engine to drive a specific component or perform a specific task.

2. Complex Mechanical Systems: Belt pulleys are also extensively used in complex mechanical systems that involve multiple components, intricate power transmission requirements, and advanced machinery. These systems often require precise speed control, synchronization of multiple shafts, and the ability to transmit power over long distances. Examples of complex mechanical systems where belt pulleys are employed include large-scale manufacturing machinery, printing presses, industrial robots, and automotive engine systems. In these applications, belt pulleys are crucial in achieving accurate power transmission, maintaining synchronization, and enabling efficient operation of the complex machinery.

3. Speed Adjustment and Variable Power Transmission: Belt pulleys are particularly advantageous in systems that require speed adjustment or variable power transmission. By using pulleys of different sizes or adjusting the position of the belt on the pulleys, the speed and power transmission characteristics can be modified. This flexibility is beneficial in both simple and complex mechanical systems. For example, in a simple mechanical system like a drill press, a belt pulley system allows for speed adjustment to accommodate different drilling requirements. In a complex mechanical system like an assembly line, belt pulleys enable variable speed control to synchronize the movement of multiple components.

4. Adaptability and Customization: Belt pulleys can be easily adapted and customized to suit the specific requirements of both simple and complex mechanical systems. They can be designed and manufactured in various sizes, materials, and configurations to accommodate different shaft diameters, space restrictions, power transmission needs, and environmental conditions. This adaptability makes belt pulleys highly versatile components that can be integrated into diverse mechanical systems, regardless of their complexity.

5. Reliability and Maintenance: Belt pulleys offer reliable and efficient power transmission in both simple and complex mechanical systems. They have a long service life when properly installed and maintained, making them a dependable choice for various applications. Regular maintenance, such as checking for proper tension, alignment, and lubrication, ensures optimal performance and prolongs the lifespan of the belt pulleys in any mechanical system.

In summary, belt pulleys are suitable for use in both simple and complex mechanical systems. They provide efficient power transmission, speed adjustment capabilities, adaptability, and reliability. Whether it’s in a small appliance or a sophisticated industrial machine, belt pulleys play a vital role in transmitting power and enabling the smooth operation of mechanical systems across a wide range of applications and industries.

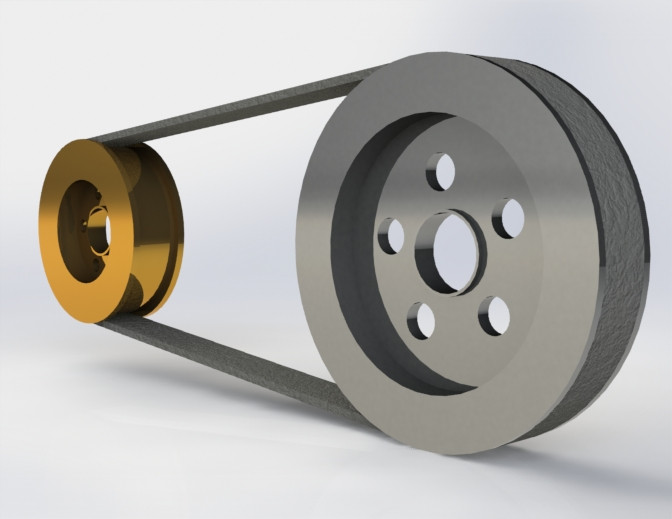

How does a belt pulley function in power transmission?

A belt pulley plays a crucial role in power transmission by enabling the transfer of rotational motion and torque between rotating shafts. It functions as a mechanical device that connects the driving shaft to the driven shaft through a belt or a rope. The rotational motion of the driving shaft is transmitted to the driven shaft via the belt pulley, allowing power to be transferred from one shaft to another. Here’s a detailed explanation:

A belt pulley functions in power transmission through the following process:

- The driving shaft, which is typically connected to a motor or an engine, rotates and generates rotational motion and torque.

- The belt pulley is mounted on the driving shaft, and its grooved rim is designed to engage with a belt or a rope.

- A belt or a rope is wrapped around the groove of the belt pulley, creating a secure connection between the pulley and the belt.

- As the driving shaft rotates, the belt or rope, in contact with the grooved rim of the pulley, starts to move.

- The movement of the belt or rope causes the belt pulley to rotate.

- Since the belt pulley is connected to the driven shaft, which is the output shaft of the system, the rotational motion of the pulley is transferred to the driven shaft.

- Consequently, the driven shaft starts to rotate at the same speed and direction as the driving shaft.

- The rotational motion and torque generated by the driving shaft are effectively transmitted to the driven shaft through the belt pulley and the belt or rope.

It’s important to note that the design and configuration of the belt pulley, along with the belt or rope, are essential for efficient power transmission. The groove profile of the pulley should match the belt or rope profile to ensure proper engagement and prevent slippage. The tension in the belt or rope should be appropriately adjusted to maintain a secure connection between the pulley and the belt. Additionally, the size and ratio of the pulleys connected by the belt can be adjusted to control the speed and torque output, providing flexibility in power transmission.

In summary, a belt pulley functions in power transmission by connecting the driving shaft to the driven shaft through a belt or a rope. It transfers the rotational motion and torque generated by the driving shaft to the driven shaft, allowing power to be transmitted between the two shafts. The design, configuration, and tensioning of the belt and the pulley are crucial for efficient and reliable power transmission in mechanical systems.

editor by CX

2024-03-30