Product Description

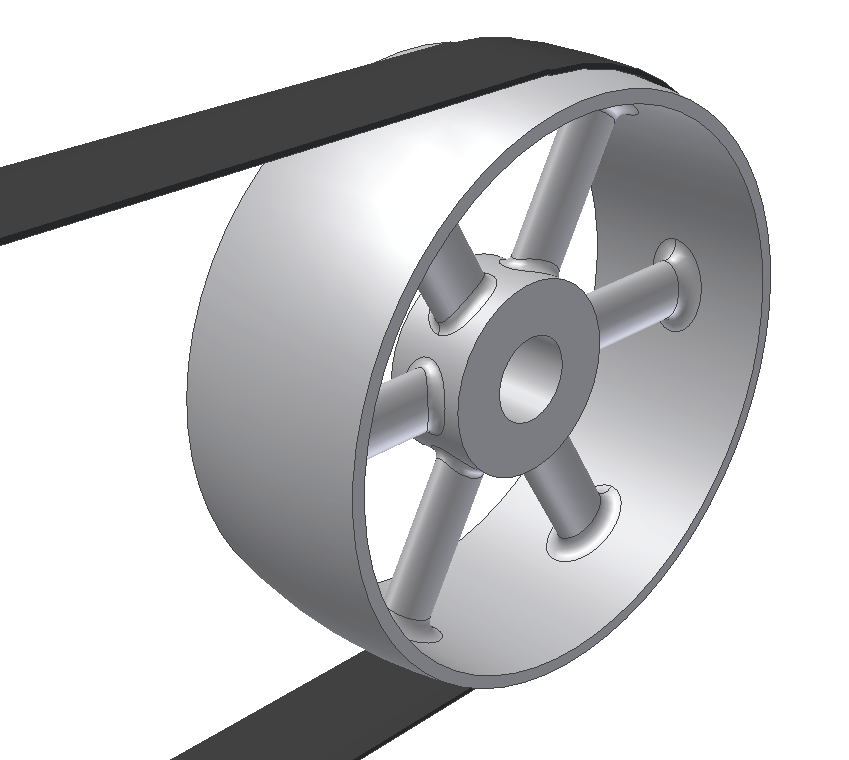

Drawings Custom 2GT 3GT 5GT 8YU Steel Synchronous Flat Timing Belt Idler Pulleys

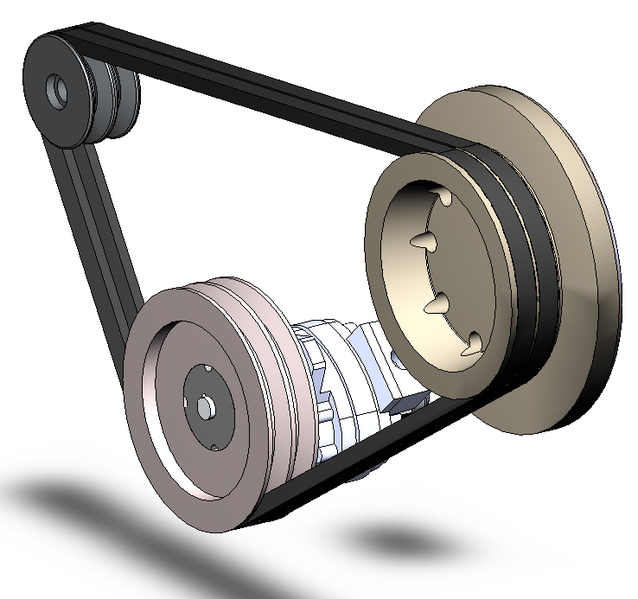

Synchronous belt pulley transmission is composed of an annular belt with equidistant teeth on the inner peripheral surface and a belt pulley with corresponding teeth. During operation, the belt teeth mesh with the tooth slots of the belt pulley to transmit motion and power. It is a new belt transmission that integrates the respective advantages of belt transmission, chain transmission and gear transmission.

Product Description

| Product | standard timing belt pulley & idler pulley |

| Customized | OEM, drawings or samples customized |

| Teeth type | Normal Torque Drive Type:MXL,XL,L,H,XH,XXH High Torque Drive Type:S2M,S3M,S5M,S8M,HTD2M,HTD3M,HTD5M,HTD8M,P2M,P3M,P5M,P8M High Precision Position Drive Type:2GT,3GT,5GT,8YU Light Load Drive Type:T5,T10,T20 Heavy Load Drive Type:AT5,AT10,AT20 |

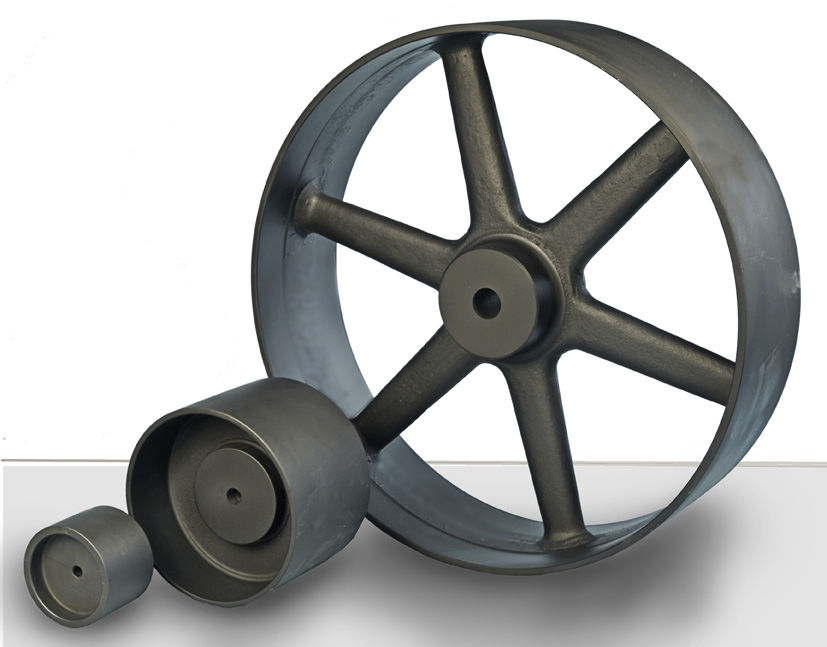

| Basic shape | Type A,Type B,Type D,Type E,Type F,Type K |

| Adaption | Adapt to 1/4 inch,5/16 inch,1/2 inch, 3/8inch, 2/25inch, 1/5inch belt |

| surface treatment | Natural color anodizing,Black anodizing,Hard anodizing,Ni-plating,Blackening |

| Material | 6061(aluminum),S45C(45# steel),SUS304(Stainless steel) |

| Bore | Pilot bore, Taper bore and Customized bore. |

| Tolerance Control | Outer diameter ±0.005mm Length dimension ±0.05mm |

| Standard | DIN, ISO/GB, AGMA, JIS |

| Teeth Accuracy | DIN Class 4, ISO/GB Classs 4, AGMA Class 13, JIS Class 0 |

| Weight | Max 15Tons |

| testing equipment | projecting apparatus,salt spray test,durometer,and coating thickness tester,2D projector |

| producing equipment | CNC machine,automatic lathe machine,stamping machine,CNC milling machine,rolling machine,lasering,tag grinding machine etc. |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching,Gear Shaving, Gear Grinding and Gear Lapping |

| Application industry | Robot industry,Medical industry,Making machine industry,Automation industry,3C industry equipment,Packaging industry,UAV industry,New energy industry. |

Company Profile

Packaging & Shipping

FAQ

| Main Markets | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| How to order | * You send us drawing or sample |

| * We carry through project assessment | |

| * We give you our design for your confirmation | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you!! |

If you are interested in our products, please tell us which materials, type, width, length u want. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type A |

| Manufacturing Process: | Forging |

| Material: | Stainless Steel |

| Surface Treatment: | Polishing |

| Application: | Machinery Parts |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do flat belt pulleys affect the performance of textile manufacturing machinery?

Flat belt pulleys have a significant impact on the performance of textile manufacturing machinery. Here’s a detailed explanation:

1. Power Transmission:

Flat belt pulleys are essential for transmitting power from the motor or engine to various components within textile manufacturing machinery. They serve as driving pulleys, connecting the power source to critical machine parts, such as spindles, rollers, and looms. The efficient power transmission facilitated by flat belt pulleys ensures the smooth operation of these components, enabling the production of high-quality textiles.

2. Speed Control:

Textile manufacturing machinery often requires precise speed control for different processes, such as spinning, weaving, or knitting. Flat belt pulleys, when used in conjunction with adjustable speed drives, allow operators to control the rotational speed of the driven components. By selecting pulleys of different sizes or adjusting the pulley positions, the speed ratios can be modified, enabling optimal machine performance and ensuring the production of textiles with consistent quality.

3. Tensioning and Tracking:

Flat belts in textile manufacturing machinery need to be properly tensioned and tracked to ensure smooth and reliable operation. Flat belt pulleys are equipped with tensioning mechanisms and tracking features to maintain the appropriate belt tension and alignment. Proper tensioning and tracking, facilitated by the pulleys, prevent belt slippage, reduce wear and tear, and minimize the occurrence of defects in textile production.

4. Belt Longevity:

Flat belt pulleys, when designed and maintained correctly, contribute to the longevity of the belts used in textile manufacturing machinery. The pulleys should have smooth surfaces and edges, minimizing friction and wear on the belts. Additionally, regular inspection and maintenance of the pulleys, including checking for proper alignment and cleaning, help prevent belt damage and extend their lifespan.

5. Noise and Vibration Reduction:

Textile manufacturing machinery often operates at high speeds, leading to noise and vibration. Properly balanced and aligned flat belt pulleys help reduce these undesirable effects by ensuring smooth and stable power transmission. Minimizing noise and vibration improves the working environment for operators and helps maintain the integrity of the textile manufacturing process.

6. Maintenance and Replacement:

Flat belt pulleys in textile manufacturing machinery are relatively easy to maintain and replace. Regular inspection and lubrication of the pulleys, along with routine belt tension checks, contribute to efficient operation and prevent unexpected breakdowns. When replacement is necessary, flat belts and pulleys are readily available, minimizing downtime and optimizing overall machine performance.

7. Cost-effectiveness:

Flat belt pulleys offer a cost-effective solution for power transmission in textile manufacturing machinery. They are relatively simple in design, require minimal maintenance, and have lower initial costs compared to alternative transmission systems. The cost-effectiveness of flat belt pulleys makes them a preferred choice in the textile industry.

Overall, flat belt pulleys play a vital role in textile manufacturing machinery by ensuring efficient power transmission, enabling speed control, maintaining belt tension and tracking, enhancing belt longevity, reducing noise and vibration, facilitating maintenance and replacement, and providing a cost-effective solution. Their proper selection, installation, and maintenance are crucial for optimal performance and productivity in textile manufacturing processes.

What safety considerations should be kept in mind when working with flat belt pulleys?

Working with flat belt pulleys involves certain safety considerations to prevent accidents and ensure safe operation. Here’s a detailed explanation:

1. Machine Guarding:

It is important to ensure that flat belt pulleys are properly guarded to prevent accidental contact with rotating parts. Guards should be in place to cover the pulley and belt, minimizing the risk of entanglement or entrapment of clothing, body parts, or tools.

2. Lockout/Tagout Procedures:

Prior to performing any maintenance or servicing tasks on machinery equipped with flat belt pulleys, proper lockout/tagout procedures should be followed. This involves isolating the power source, locking out the equipment, and clearly tagging it to indicate that maintenance work is in progress. This helps to prevent inadvertent startup of the machinery, which could cause serious injuries.

3. Personal Protective Equipment (PPE):

When working with flat belt pulleys, appropriate Personal Protective Equipment (PPE) should be worn. This may include safety glasses or goggles to protect the eyes from debris or flying particles, gloves to protect hands from sharp edges or pinch points, and hearing protection if the machinery generates excessive noise.

4. Training and Education:

Operators and maintenance personnel should receive proper training and education on the safe operation and maintenance of machinery with flat belt pulleys. They should be familiar with the potential hazards associated with these systems and understand the correct procedures for installation, tensioning, and adjustment of the belts.

5. Regular Inspections and Maintenance:

Flat belt pulleys should be regularly inspected for signs of wear, damage, or misalignment. Any issues should be addressed promptly to prevent further damage or potential accidents. Routine maintenance, including belt replacement, lubrication, and tension adjustments, should be performed according to the manufacturer’s recommendations.

6. Handling Heavy Loads:

When working with machinery that utilizes flat belt pulleys for heavy load transmission, proper lifting techniques should be employed to prevent strains or injuries. Mechanical lifting aids or equipment should be used as necessary to safely handle heavy loads.

7. Risk Assessment:

A thorough risk assessment should be conducted to identify and mitigate potential hazards associated with flat belt pulleys. This includes evaluating the layout of the machinery, the positioning of pulleys and belts, and any other factors that may pose a risk to the safety of operators or maintenance personnel.

By adhering to these safety considerations, the risk of accidents or injuries when working with flat belt pulleys can be significantly reduced. It is essential to follow industry best practices, manufacturer’s guidelines, and applicable safety regulations to ensure the safe operation of machinery equipped with flat belt pulleys.

How do flat belt pulleys differ from other types of pulleys?

Flat belt pulleys have distinct characteristics that set them apart from other types of pulleys. Here’s a detailed explanation:

1. Belt Type:

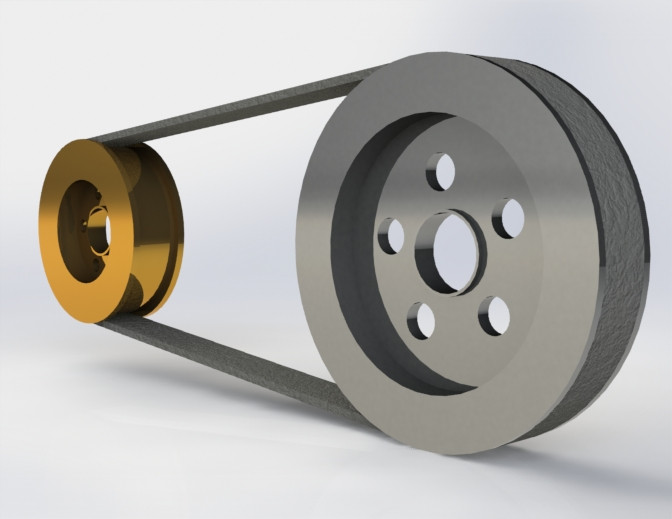

The major difference lies in the type of belt used. Flat belt pulleys are specifically designed to work with flat belts, which are flexible and have a rectangular cross-section. In contrast, other types of pulleys, such as V-belt pulleys or timing belt pulleys, are designed for different belt profiles, such as V-shaped belts or toothed belts.

2. Belt Engagement:

Flat belt pulleys engage with the belt differently compared to other pulley types. The flat belt wraps around the pulley’s flat or slightly concave surface and relies on friction to transmit power. Other pulley types, like V-belt pulleys, have grooves that match the shape of the belt, providing positive engagement by fitting into the belt’s grooves.

3. Power Transmission:

Each pulley type is optimized for specific power transmission requirements. Flat belt pulleys are often used for applications that require relatively low power and moderate speeds. They are suitable for machinery that needs flexibility and ease of installation, making them commonly used in older machinery and certain industrial applications. Other pulley types, like V-belt pulleys or timing belt pulleys, offer advantages for high-power transmission, increased efficiency, or precise timing in applications such as automotive engines or industrial machinery.

4. Pulley Design:

Flat belt pulleys have a simple design, typically consisting of a cylindrical or disk-shaped body with a flat or slightly concave surface. Other pulley types may have more complex designs to accommodate specific belt profiles. For example, V-belt pulleys have grooves that match the V-shaped belts, while timing belt pulleys have toothed profiles that match the teeth on the timing belts.

5. Speed and Torque Conversion:

The design and configuration of pulleys, including flat belt pulleys, allow for speed and torque conversion. By varying the sizes of the pulleys, the speed and torque can be adjusted to meet the requirements of the machinery. However, the specific mechanisms for speed and torque conversion may differ between pulley types. For example, V-belt pulleys rely on the varying diameters of the pulleys to achieve speed conversion, while timing belt pulleys use the toothed profiles to ensure precise timing and synchronization.

6. Belt Tension and Alignment:

The methods used to maintain belt tension and alignment can also differ between pulley types. Flat belt pulleys often rely on adjustable pulley positions or tensioning mechanisms to achieve proper tension and alignment. Other pulley types may incorporate features like automatic tensioners or specialized tensioning systems to maintain optimal belt performance.

In conclusion, flat belt pulleys differ from other types of pulleys in terms of the belt type, engagement method, power transmission capabilities, design, speed and torque conversion mechanisms, as well as belt tension and alignment methods. Understanding these differences is crucial for selecting the appropriate pulley type for a given application.

editor by CX

2024-04-16