Product Description

Conveyor Pulley is manufactured as per customer requirement,with main design under national standard,quality inspection focusing on shaft core,welded joint,rubber material and hardness,dynamic balance and so on for longer product life time.

| Drive/Head Pulley – A conveyor pulley used for the purpose of driving a conveyor belt. Typically mounted in external bearings and driven by an external drive source. |

| Return/Tail Pulley – A conveyor pulley used for the purpose of redirecting a conveyor belt back to the drive pulley. Tail pulleys can utilize internal bearings or can be mounted in external bearings and are typically located at the end of the conveyor bed. Tail pulleys commonly serve the purpose of a Take-Up pulley on conveyors of shorter lengths. |

| Snub Pulley – A conveyor pulley used to increase belt wrap around a drive pulley, typically for the purpose of improving traction. |

| Take-Up Pulley – A conveyor pulley used to remove slack and provide tension to a conveyor belt. Take-Up pulleys are more common to conveyors of longer lengths. |

| Bend Pulley – A conveyor pulley used to redirect the belt and provide belt tension where bends occur in the conveyor system. |

The specification of pulley:

Drive Drum: is the main component of power transmission. The drum can be divided into single drum (the angle of the belt to the drum is 210 ° ~ 230 °) , Double Drum (the angle of the belt to the drum is up to 350 °) and

multi-drum (used for high power) .

Bend Drum: is used for changing the running direction of the conveyor belt or increasing the surrounding angle of the conveyor belt on the driving roller, and the roller adopts a smooth rubber surface . The drum shaft shall be forgings and shall be nondestructive tested and the inspection report shall be provided.

The Various Surface of Pulley:

Conveyor pulley lagging is essential to improve conveyor belt performance, the combination of our pulley lagging can reduces belt slippage, improve tracking and extends life of belt, bearing & other components.

| PLAIN LAGGING:This style of finish is suitable for any pulley in the conveyor system where watershed is not necessary. It provides additional protection against belt wear, therefore, increasing the life of the pulley. |

| DIAMOND GROOVE LAGGING:This is the standard pattern on all Specdrum lagged conveyor pulleys. It is primarily used for reversing conveyor drive pulleys. It is also often used to allow bi-directional pulley rotation, and the pattern allows water to be dispersed away from the belt. |

| HERRINGBONE LAGGING:The herringbone pattern’s grooves are in the direction of rotation, and offers superior tractive properties. Each groove allows water and other liquids to escape between the face of the drum pulley and the belt. Herringbone grooved pulleys are directional and should be applied to the conveyor in a manner in which the grooves point toward the direction of the belt travel. |

| CHEVRON LAGGING:Some customers specify that the points of the groove should meet – as done in Chevron styled lagging. As before with the herringbone style, this would be used on drive drum pulleys and should be fitted in the correct manner, so as to allow proper use of the pattern and water dispersion also. |

| CERAMIC LAGGING:The Ceramic tiles are moulded into the lagging which is then cold bonded to the drum pulley. This style of finish allows excellent traction and reduces slippage, meaning that the belt tension is lower and, therefore as a result, increases the life of the pulley. |

| WELD-ON STRIP LAGGING: Weld-On Strip Lagging can be applied to bi-directional pulleys, and also has a finish to allow the easy dispersion of water or any fluids between the drum pulley and the belt. |

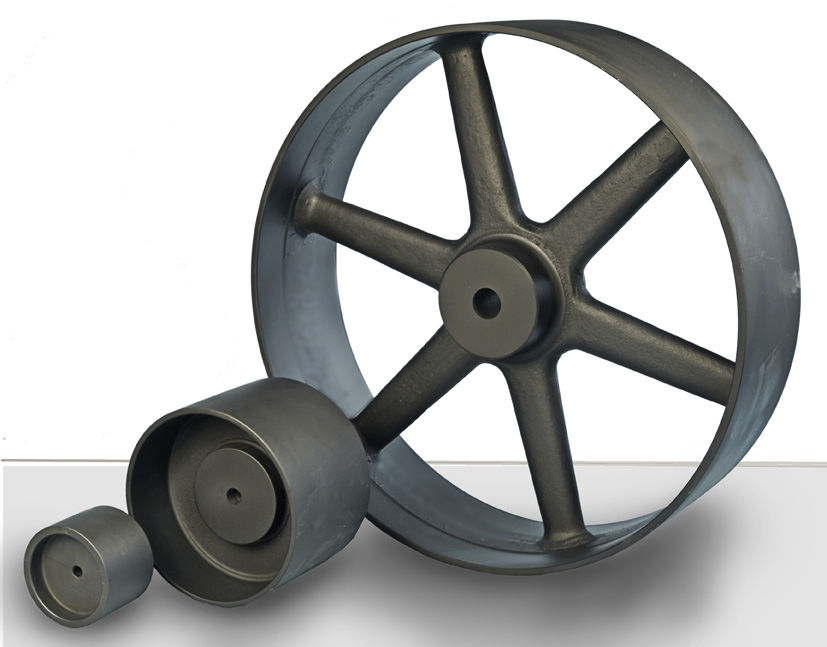

The Components of Pulley:

| 1. Drum or Shell:The drum is the portion of the pulley in direct contact with the belt. The shell is fabricated from either a rolled sheet of steel or from hollow steel tubing. |

| 2.Diaphragm Plates: The diaphragm or end plates of a pulley are circular discs which are fabricated from thick steel plate and which are welded into the shell at each end, to strengthen the drum.The end plates are bored in their centre to accommodate the pulley Shaft and the hubs for the pulley locking elements. |

| 3.Shaft :The shaft is designed to accommodate all the applied forces from the belt and / or the drive unit, with minimum deflection. The shaft is located and locked to the hubs of the end discs by means of a locking elements. The shaft and hence pulley shafts are often stepped. |

| 4.Locking Elements:These are high-precision manufactured items which are fitted over the shaft and into the pulley hubs. The locking elements attach the pulley firmly to the shaft via the end plates. |

| 5.Hubs:The hubs are fabricated and machined housings which are welded into the end plates. |

| 6.Lagging: It is sometimes necessary or desirable to improve the friction between the conveyor belt and the pulley in order to improve the torque that can be transmitted through a drive pulley. Improved traction over a pulley also assists with the training of the belt. In such cases pulley drum surfaces are `lagged` or covered in a rubberized material. |

| 7.Bearing: Bearings used for conveyor pulleys are generally spherical roller bearings, chosen for their radial and axial load supporting characteristics. The bearings are self-aligning relative to their raceways, which means that the bearings can be ‘misaligned’ relative to the shaft and plummer blocks, to a certain degree. In practical terms this implies that the bending of the shaft under loaded conditions as well as minor misalignment of the pulley support structure, can be accommodated by the bearing. |

The Production Process of Pulley:

Our Products:

| 1.Different types of Laggings can meet all kinds of complex engineering requirements. |

| 2.Advanced welding technology ensures the connection strength between Shell and End-Disk. |

| 3.High-strength Locking Elements can satisfy torque and bending requirements. |

| 4.T-shape End-Discs provide highest performance and reliability. |

| 5.The standardized Bearing Assembly makes it more convenient for the end user to replace it. |

| 6.Excellent raw material and advanced processing technology enable the shaft can withstand enough torque. |

| 7.Low maintenance for continued operation and low total cost of ownership. |

| 8.Scientific design process incorporating Finite Element Analysis. |

Our Workshop:

| MACHINE:We have advanced laser cutting machines, a complete set of intelligent sheet metal forming equipment, robot welding and other processing and testing equipment. |

| PAINTING: We use electrostatic spraying to ensure variety, model and quality of coatings, thinners and curing agents should meet the design requirements and the current relevant national standards. The steel surface should be free of welding slag, welding scars, dust, oil, water and burrs before painting. No mispainting or omission, and the coating should be free of peeling and rust. Inspection method: observation and inspection. Uniform brushing, consistent color, no wrinkles,sagging and bubbles, good adhesion, and the color separation line should be clear and neat. |

| DELIVERY:The goods and product factory certificate, installation and use instructions and drawings, a full set of connectors. After the equipment arrives at the site, the company immediately arranges professional and technical personnel to guide the installation on site to provide customers with satisfactory services. |

| PACKAGE:Packed with steel frame or wooden box, according to the standardfor trade export or according to the special requirements of customers. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Surface Treatment: | Baking Paint |

| Motor Type: | Frequency Control Motor |

| Installation: | Horizontal |

| Carrying Type: | Light, Medium, Heavy |

| Light Bearing Aperture: | 80-100mm |

| Samples: |

US$ 40/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How are belt pulleys employed in agricultural machinery and equipment?

Belt pulleys play a crucial role in agricultural machinery and equipment, contributing to various functions and operations in the agricultural industry. They are used in a wide range of applications, from power transmission and driving different agricultural implements to controlling the speed and functionality of various systems. Here’s a detailed explanation of how belt pulleys are employed in agricultural machinery and equipment:

1. Power Transmission: Belt pulleys are extensively used for power transmission in agricultural machinery. They serve as the driving force to transfer power from the tractor’s power take-off (PTO) to different agricultural implements. The PTO pulley, connected to the tractor’s PTO shaft, drives the belt, which, in turn, drives the pulleys on the implements, such as mowers, balers, harvesters, and seeders. This power transmission enables the implements to perform their specific functions effectively.

2. Crop Harvesting and Processing: Belt pulleys are employed in various agricultural machinery involved in crop harvesting and processing. For example, in combine harvesters, belt pulleys are used to drive the cutting mechanism, threshing drum, and grain conveyors. The rotation of the pulleys enables the harvesting and separation of crops from the fields. In processing equipment like grain elevators and conveyors, belt pulleys facilitate the movement of harvested crops for storage or further processing.

3. Irrigation Systems: Belt pulleys are utilized in irrigation systems in agriculture. In irrigation pumps, belt pulleys connect the pump’s drive shaft to the power source, such as an electric motor or a tractor’s PTO. The rotation of the pulleys drives the pump, which boosts water pressure and facilitates irrigation by distributing water to crops through sprinklers, drip lines, or other irrigation methods.

4. Feed and Forage Processing: Belt pulleys are employed in machinery used for feed and forage processing in the agricultural industry. For instance, in feed mixers, belt pulleys drive the mixing auger or paddle mechanism, ensuring thorough blending of different feed ingredients. In forage choppers or silage harvesters, belt pulleys drive the cutting mechanism and the feed rollers, enabling the efficient harvesting and chopping of forage crops.

5. Livestock Equipment: Belt pulleys are used in various livestock equipment and machinery. In milking machines, belt pulleys drive the vacuum pump, creating suction for milking cows. Conveyor systems for livestock feed or manure management also employ belt pulleys to transport feed or handle manure efficiently. Additionally, in barn ventilation systems, belt pulleys drive the fans, facilitating air circulation and maintaining optimal environmental conditions for livestock.

6. Speed Control and Functionality: Belt pulleys are utilized to control the speed and functionality of different agricultural machinery. By using pulleys of varying sizes or adjusting the pulley arrangement, the speed of the driven implements or systems can be modified to suit specific agricultural operations. This allows for customization and adaptability in tasks such as soil cultivation, planting, spraying, and material handling.

7. Custom Applications: Belt pulleys are also employed in custom applications in agriculture, depending on specific requirements. Farmers and equipment manufacturers may design and incorporate belt pulleys in unique ways to drive specialized equipment, such as conveyor systems, grain cleaners, hay baling systems, or other agricultural machinery tailored to their specific needs.

In summary, belt pulleys have diverse applications in agricultural machinery and equipment. From power transmission and driving agricultural implements to controlling speed, facilitating crop harvesting and processing, supporting irrigation systems, and enabling functionality in various equipment, belt pulleys play a vital role in optimizing agricultural operations and enhancing productivity in the agricultural industry.

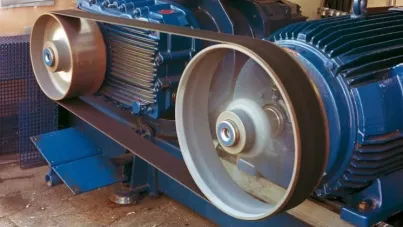

How do belt pulleys contribute to the operation of conveyor systems for material handling?

Belt pulleys play a crucial role in the operation of conveyor systems for material handling. Conveyor systems are widely used in industries such as manufacturing, mining, logistics, and agriculture to transport bulk materials or goods from one location to another. The belt pulleys in these systems contribute significantly to their functionality, efficiency, and reliability. Here’s a detailed explanation of how belt pulleys contribute to the operation of conveyor systems for material handling:

1. Power Transmission: Belt pulleys serve as the driving force for conveyor systems, transmitting power from an electric motor or engine to move the conveyor belt. The pulley is typically connected to the motor or engine shaft, and as it rotates, it drives the belt, which in turn transports the materials along the conveyor. The size and design of the pulley, along with the tension in the belt, determine the power transmission efficiency and the capacity of the conveyor system to handle different load weights and volumes.

2. Belt Tension and Tracking: Belt pulleys help maintain proper tension and tracking of the conveyor belt. Tensioning pulleys are used to adjust and maintain the tension in the belt, ensuring it remains taut and properly engaged with the pulleys. Tracking pulleys, also known as snub or bend pulleys, are strategically positioned to guide the belt and keep it centered on the pulley system. Proper tension and tracking prevent belt slippage, misalignment, and material spillage, ensuring smooth and reliable operation of the conveyor system.

3. Speed Control: Belt pulleys enable speed control in conveyor systems. By using different-sized pulleys or adjusting the pulley arrangement, the speed of the conveyor belt can be modified to suit specific material handling requirements. Speed control is essential for optimizing production processes, accommodating different material characteristics, and ensuring efficient material flow along the conveyor system.

4. Directional Changes: Belt pulleys facilitate directional changes in conveyor systems. By incorporating various pulley configurations, such as drive pulleys, idler pulleys, and bend pulleys, the conveyor belt can be guided around curves or redirected to different paths. This allows for flexible routing and layout of the conveyor system to adapt to space constraints or specific material flow patterns in material handling operations.

5. Load Distribution: Belt pulleys contribute to the even distribution of the load on the conveyor belt. As the belt wraps around the pulleys, the contact area between the belt and pulley surface spreads the load across a larger surface area. This load distribution minimizes stress concentration, reduces belt wear, and extends the operational life of the conveyor system.

6. Maintenance and Safety: Belt pulleys play a role in the maintenance and safety of conveyor systems. Accessible pulleys allow for easy inspection, cleaning, and maintenance of the conveyor belt. Pulley guards and covers provide protection against accidental contact with moving parts, enhancing the safety of personnel working around the conveyor system.

7. Customization and Adaptability: Belt pulleys can be customized and designed to meet specific material handling requirements. They can be manufactured in various sizes, materials, and configurations to accommodate different belt widths, load capacities, and environmental conditions. This customization ensures that the belt pulleys are optimized for the specific needs of the material handling application.

In summary, belt pulleys are integral components of conveyor systems for material handling. They contribute to power transmission, belt tensioning, speed control, directional changes, load distribution, and overall system maintenance and safety. By utilizing appropriately sized and designed belt pulleys, conveyor systems can efficiently and reliably transport bulk materials or goods, enhancing productivity and streamlining material handling operations in various industries.

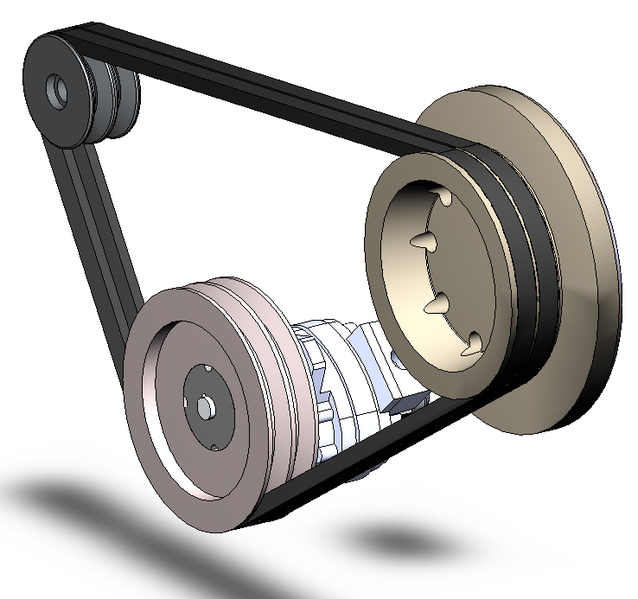

How does a belt pulley function in power transmission?

A belt pulley plays a crucial role in power transmission by enabling the transfer of rotational motion and torque between rotating shafts. It functions as a mechanical device that connects the driving shaft to the driven shaft through a belt or a rope. The rotational motion of the driving shaft is transmitted to the driven shaft via the belt pulley, allowing power to be transferred from one shaft to another. Here’s a detailed explanation:

A belt pulley functions in power transmission through the following process:

- The driving shaft, which is typically connected to a motor or an engine, rotates and generates rotational motion and torque.

- The belt pulley is mounted on the driving shaft, and its grooved rim is designed to engage with a belt or a rope.

- A belt or a rope is wrapped around the groove of the belt pulley, creating a secure connection between the pulley and the belt.

- As the driving shaft rotates, the belt or rope, in contact with the grooved rim of the pulley, starts to move.

- The movement of the belt or rope causes the belt pulley to rotate.

- Since the belt pulley is connected to the driven shaft, which is the output shaft of the system, the rotational motion of the pulley is transferred to the driven shaft.

- Consequently, the driven shaft starts to rotate at the same speed and direction as the driving shaft.

- The rotational motion and torque generated by the driving shaft are effectively transmitted to the driven shaft through the belt pulley and the belt or rope.

It’s important to note that the design and configuration of the belt pulley, along with the belt or rope, are essential for efficient power transmission. The groove profile of the pulley should match the belt or rope profile to ensure proper engagement and prevent slippage. The tension in the belt or rope should be appropriately adjusted to maintain a secure connection between the pulley and the belt. Additionally, the size and ratio of the pulleys connected by the belt can be adjusted to control the speed and torque output, providing flexibility in power transmission.

In summary, a belt pulley functions in power transmission by connecting the driving shaft to the driven shaft through a belt or a rope. It transfers the rotational motion and torque generated by the driving shaft to the driven shaft, allowing power to be transmitted between the two shafts. The design, configuration, and tensioning of the belt and the pulley are crucial for efficient and reliable power transmission in mechanical systems.

editor by CX

2024-03-29