Product Description

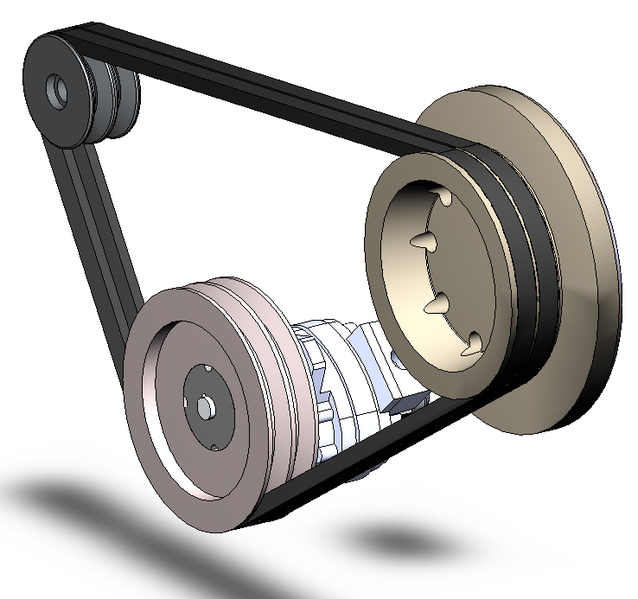

Aluminum Synchronous Flat Belt Custom Pulley

Introduction for custom pulley:

Xihu (West Lake) Dis. CHINAMFG CHINAMFG Precision Machining Co., ltd, which is a manufacturer specializing in the machining parts with rich manufacturing and design experience.

Our products include: gringing parts, machining parts, turning parts, lathe parts, milling parts, CNC milling parts, CNC machining parts, CNC turning parts, CNC lathe parts, CNC metal parts, stamping parts, casting and forging parts, assembly service, laser cutting parts, flange and fitting, die casting parts, metal stamping parts, gear and transmission, aluminum profile, automation group, punch parts, and all kinds of custom/customize parts.

Welcome to send us your drawing for CNC parts machining service, we can customize as your requirement.

Our Company for custom pulley:

Technical parameter of custom pulley:

| 1. Material | Aluminum, Brass, Bronze, Copper, Hardened Metals |

| 2. Tolerance | +/-0.05mm |

| 3. Finishing | anodizing, polishing, plating, blacken ect |

| 4. Edges and holes | debarred |

| 5. Surfaces | free of scratches |

| 6. Material capabilities | aluminum, stainless steel, copper, plastic and more |

| 7. Various materials and finishing ways are available | |

| 8. Non-standard aluminum product | |

| 9. Material and finishing comply with RoHS Directive | |

| 10. Small orders are welcome | |

Payment and shipping for custom pulley:

After Service for custom pulley:

Welcome consult with us, we service:

1. Best Solution for your production.

2. Fast delivery for your urgent order.

3. 24Hour online

Surface treatment for custom pulley:

| 1 | Zinc/nickel/chrome plating |

| 2 | hot galvanized |

| 3 | painting |

| 4 | powder coating |

| 5 | Anodize Oxidation, or with colors: like silver, blue, red, etc. |

| 6 | plating, silver-plated, Gold-plated, etc |

| 7 | polishing |

| 8 | electrolytic polishing |

| 9 | sank without electricity nickel |

| etc | etc. |

Detail material sheet for custom pulley:

| Aluminum | 6061-T6, 6063-T5, 7075-T6, 2011, 2017, 2571, 5052, 5083, 6082, etc |

| Stainless steel | SUS303, SUS304, SUS316, SUS316L, SUS430, SUS440, SUS420, SUS201, etc. |

| Steel | Q235, 20#, 45#, Cr12, SKD11, A2, 40Cr, 16Mn, Cr12Mov, etc. |

| Carbon Steel | 1571, 1015, 1571, 1030, 1035, 1040, 1045, etc. |

| Free Cutting Steel | 1211, 12L13, 12L14, 1215, etc. |

| Brass | C11000, C15710, C12000, C26000(HPb59), C36000(C26800), C38500(HPb58, C27200(CuZn37), C28000(CuZn4 |

| Plastic | PVC, PE, PMMA, POM, Telfon, Delrin, PEEK, Nylon, ABS, PC, PP, PA6, PA66, etc. |

Our Experience for custom pulley:

We are with rich experience in processing of various materials,

such as AL6061/7075, SUS303, 304, ESD225/420, DERLIN, SI36H, SS440C, 17-4 ph, Ceramic, Carbide, Engineering Plastics such as PEEK and so on. In addition, we can also provide some special processing, special heat treatment and special electroplating, surface treatment for customer, such as optical grinding, honing, precision EDM specialshaped processing, carburizing, nitriding, vacuum heat treatment and cryogenic treatment, the hard anodized aluminum, steel blue, electrolytic polishing, nickel sank without electricity, silver-plated, gold-plated and so on.

Material: Copper, iron, aluminum, stainless steel, alloy steel, plastic. etc. Which we usually processing are as following show.

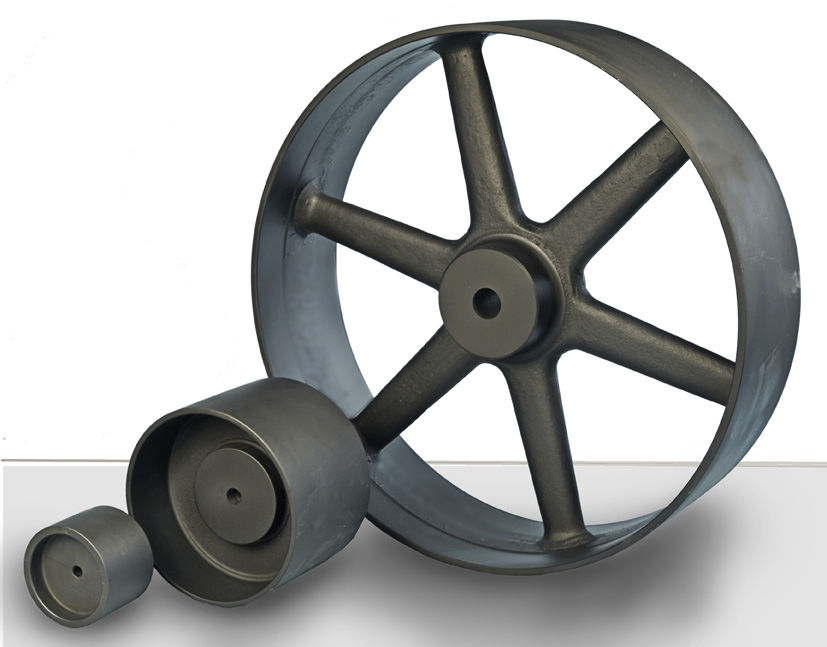

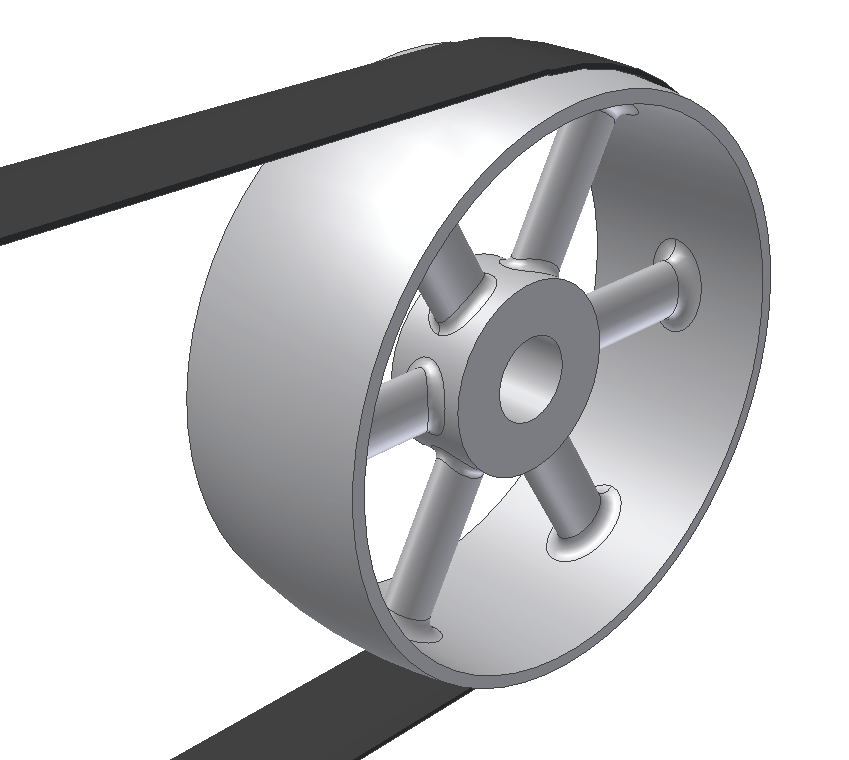

More pictures of custom pulley with different material:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Certification: | ISO9001 |

| Standard: | GB |

| Customized: | Customized |

| Material: | Aluminum |

| Application: | Metal Recycling Machine, Metal Casting Machinery |

| Samples: |

US$ 80/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

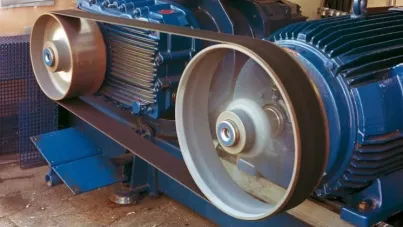

Can flat belt pulleys be integrated into conveyor systems for material handling?

Yes, flat belt pulleys can be effectively integrated into conveyor systems for material handling. Here’s a detailed explanation:

Conveyor systems are widely used in industries for the efficient movement of materials from one location to another. Flat belt pulleys offer several advantages when incorporated into conveyor systems:

1. Power Transmission:

Flat belt pulleys are used as the driving pulleys in conveyor systems. They transmit power from a motor or an engine to the belt, enabling the movement of materials along the conveyor. The large contact area and grip between the pulleys and the belt ensure efficient power transfer, allowing for the transportation of various types of materials.

2. Load Capacity:

Flat belt pulleys are designed to handle different load capacities. They can be selected based on the specific requirements of the conveyor system, such as the weight and type of materials being transported. The pulley’s diameter and width are chosen to provide adequate support and load-bearing capacity for the belt.

3. Belt Tracking:

Proper belt tracking is crucial in conveyor systems to prevent belt misalignment and ensure smooth operation. Flat belt pulleys are designed with features such as flanges or guides to help keep the belt centered and aligned. This ensures that the materials are conveyed along the desired path without any disruptions or spillage.

4. Belt Tensioning and Adjustability:

Flat belt pulleys in conveyor systems are equipped with tensioning mechanisms to maintain the appropriate belt tension. These mechanisms, such as idler pulleys or tensioning screws, allow for easy adjustment of the belt tension to accommodate variations in load or belt stretch over time. Proper tensioning ensures efficient power transmission and prevents belt slippage.

5. Versatility:

Flat belt pulleys offer versatility in conveyor system design. They can be used in straight conveyors, curved conveyors, or inclined conveyors, allowing for the transportation of materials in various directions and angles. The flexibility of flat belts also enables efficient movement around pulleys of different sizes and configurations.

6. Maintenance and Replacement:

Flat belt pulleys in conveyor systems are relatively easy to maintain and replace. Regular inspection and maintenance of the pulleys, including checking for proper alignment and tension, can help prevent issues and ensure efficient operation. When replacement is necessary, flat belts and pulleys are readily available, minimizing downtime and optimizing material handling efficiency.

Consequently, flat belt pulleys are commonly integrated into conveyor systems for material handling due to their efficient power transmission, load capacity, versatility, and ease of maintenance. They are widely used in industries such as manufacturing, warehousing, mining, agriculture, and logistics.

How do flat belt pulleys handle different belt sizes and materials?

Flat belt pulleys are designed to accommodate different belt sizes and materials to ensure efficient power transmission. Here’s a detailed explanation:

1. Belt Sizes:

Flat belt pulleys are available in various sizes to match different belt widths and thicknesses. The width of the pulley’s groove is designed to provide proper contact and grip with the belt. Pulleys with wider grooves are used for wider belts, while narrower grooves are used for narrower belts. The pulley’s diameter may also vary depending on the specific application and power requirements.

2. Belt Materials:

Flat belt pulleys can handle a wide range of belt materials, including:

- Rubber: Rubber belts are commonly used due to their flexibility, high friction coefficient, and resistance to wear. They provide good grip and are suitable for most general-purpose applications.

- Polyurethane: Polyurethane belts offer high resistance to abrasion, oil, and chemicals. They are often used in applications that require superior performance and durability.

- Leather: Leather belts are known for their high strength and flexibility. They are used in applications where a certain level of slip is required or to transmit power in antique or vintage machinery.

- Nylon: Nylon belts are lightweight, have high tensile strength, and offer good resistance to wear and moisture. They are commonly used in applications that require low noise and high load capacity.

3. Belt Tensioning:

Flat belt pulleys should be designed with a tensioning mechanism to accommodate different belt sizes and maintain proper tension. This mechanism, such as an idler pulley or tensioning screw, allows for easy adjustment of the belt tension to ensure optimal power transmission and prevent slippage.

4. Belt Tracking:

To handle different belt sizes and materials, flat belt pulleys should be designed to provide proper belt tracking. This ensures that the belt stays within the pulley’s groove and maintains alignment during operation. Proper flanges or guides are often incorporated into the pulley design to prevent the belt from slipping off or wandering.

5. Material Compatibility:

The materials used in flat belt pulleys should be selected to be compatible with the specific belt materials. For example, if using a rubber belt, the pulley material should not cause excessive wear or damage to the belt’s surface. Compatibility between the pulley and the belt material helps ensure optimal performance and longevity.

By considering these factors, flat belt pulleys can effectively handle different belt sizes and materials, providing reliable power transmission in a wide range of applications.

What is a flat belt pulley, and how does it function in machinery?

A flat belt pulley is a type of pulley used in machinery that utilizes a flat belt for power transmission. Here’s a detailed explanation:

1. Design and Construction:

A flat belt pulley consists of a cylindrical or disk-shaped body with a flat or slightly concave surface. It is typically made of durable materials such as cast iron, steel, or aluminum. The pulley may have one or more grooves or channels on its surface to accommodate the flat belt, ensuring proper engagement and power transfer.

2. Power Transmission:

The primary function of a flat belt pulley is to transmit power from a driving source, such as an engine or motor, to a driven component in machinery. The flat belt connects the driving pulley (also known as the driver) to the driven pulley (also known as the driven). As the driving pulley rotates, it imparts rotational motion to the flat belt, which in turn transfers the power to the driven pulley. This enables the driven component to perform its intended function.

3. Belt Grip and Traction:

A flat belt pulley provides grip and traction on the flat belt, ensuring efficient power transfer and minimizing slippage. The design of the pulley surface, including any grooves or channels, helps maintain proper belt engagement and prevents the belt from slipping or coming off the pulley during operation. The pulley’s material and surface finish are chosen to optimize friction and traction between the pulley and the belt.

4. Speed and Torque Conversion:

By varying the size of the flat belt pulleys in a machinery system, the rotational speed and torque can be converted according to the desired requirements. The ratio of the pulley diameters determines the speed ratio between the driving and driven components. For example, a larger pulley on the driving side and a smaller pulley on the driven side will result in increased speed at the driven component but reduced torque. This allows for the customization and adaptation of machinery to different operational needs.

5. Tension and Alignment:

A flat belt pulley aids in maintaining proper tension and alignment of the flat belt. Tensioning mechanisms, such as adjustable pulley positions or tensioners, are utilized to ensure optimal tension in the belt. Proper tension prevents slippage and ensures the belt remains tightly engaged with the pulleys. Additionally, flat belt pulleys may incorporate features like crowned surfaces or tracking guides to aid in belt alignment, reducing the risk of misalignment and optimizing power transmission.

6. Maintenance and Replacement:

Regular maintenance and inspection of flat belt pulleys are essential for their proper functioning. It is important to check for wear, damage, or misalignment of the pulley and the flat belt. Any worn or damaged pulleys should be replaced promptly to prevent performance issues and potential failures in the machinery.

In summary, a flat belt pulley is a key component in machinery for power transmission using flat belts. It provides grip and traction, facilitates speed and torque conversion, aids in tension and alignment, and requires regular maintenance to ensure optimal performance.

editor by CX

2024-04-29