Product Description

Product Description

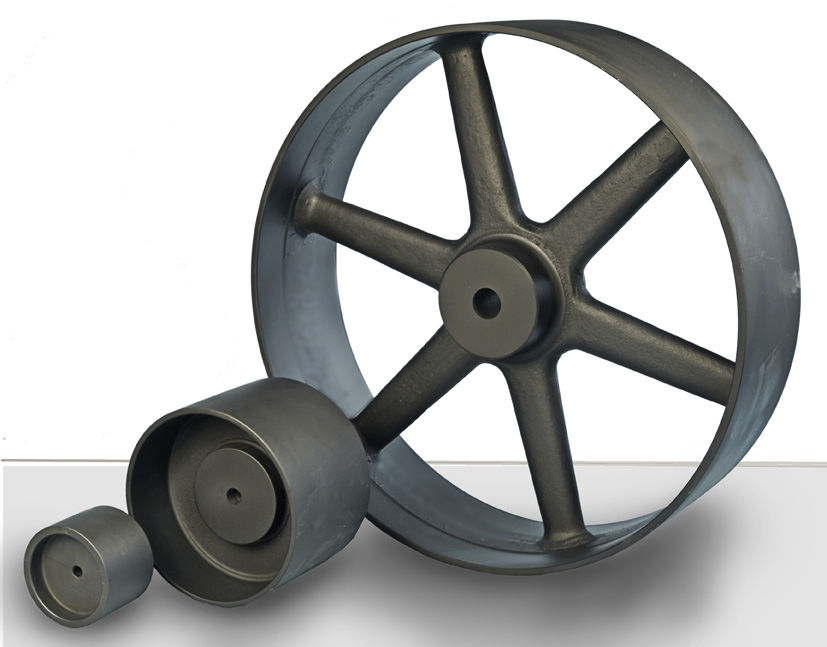

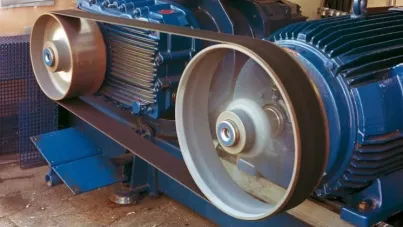

A conveyor will always consist of at least 2 pulleys, head pulley and tail pulley, with additional pulleys used depending on the configuration. Standard-duty pulleys are usually adequate for simple applications, but mine-duty and engineered pulleys are also available where heavy-duty pulleys are required.

Different kinds of conveyor pulleys

KONWEYOUR sells conveyor pulleys in all the following sub-categories:

Head pulleys

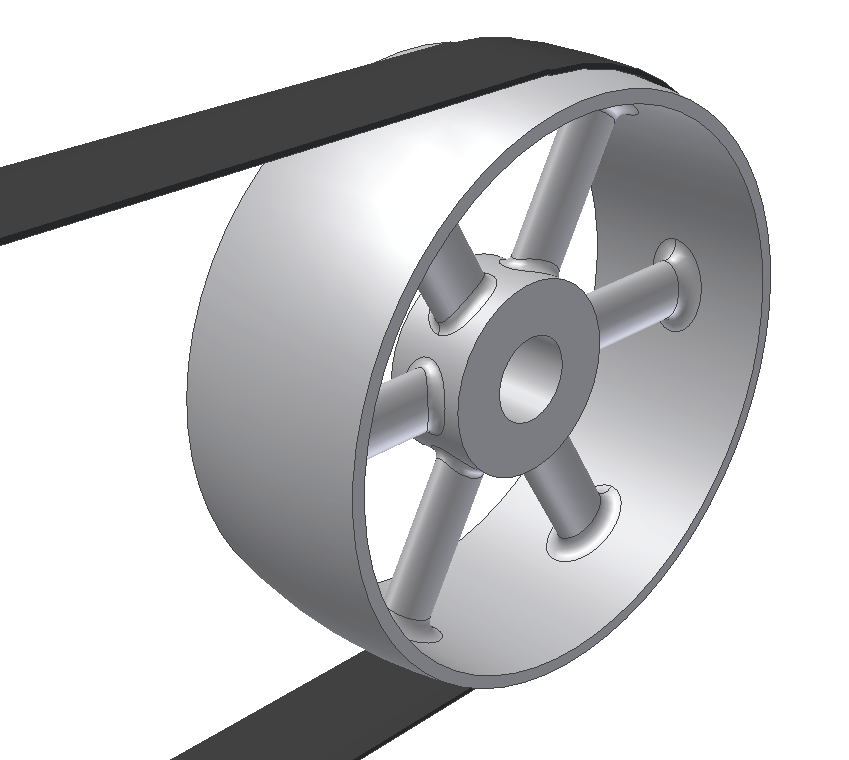

The head pulley is located at the discharge point of the conveyor. It usually drives the conveyor and often has a larger diameter than other pulleys. For better traction, the head pulley is usually lagged (with either rubber or ceramic lagging material).

Tail and CHINAMFG pulleys

The tail pulley is located at the loading end of the belt. It comes with either a flat face or a slatted profile (wing pulley), which cleans the belt by allowing material to fall between the support members.

Snub pulleys

A snub pulley improves the traction of the drive pulley, by increasing its belt wrap angle.

Drive pulleys

Drive pulleys, which can also be the head pulley, are driven by a motor and power transmission unit to propel the belt and material to the discharge.

Bend pulleys

A bend pulley is used for changing the direction of the belt.

Take-up pulley

A take-up pulley is used to provide the belt with the proper amount of tension. Its position is adjustable.

Product Parameters

| Type | Belt width(mm) | Standard Diameter(mm) | Length(mm) |

| Drive Pulley | 500 | 500 |

Length of the pulley depends on the belt width of the conveyor |

| 650 | 500~630 | ||

| 800 | 630~1000 | ||

| 1000 | 800~1150 | ||

| 1200 | 800~1150 | ||

| 1400 | 1000~1350 | ||

| 1600 | 1150~1600 | ||

| 1800 | 1150~1800 | ||

| 2000 | 1350~2000 | ||

| 2200 | 1600~2200 | ||

| 2400 | 1800~2400 | ||

| Bend Pully | 500 | 250~500 | |

| 650 | 250~630 | ||

| 800 | 250~1000 | ||

| 1000 | 250~1600 | ||

| 1200 | 250~1600 | ||

| 1400 | 315~1600 | ||

| 1600 | 400~1600 | ||

| 1800 | 400~1600 | ||

| 2000 | 500~1600 | ||

| 2200 | 630~1600 | ||

| 2400 | 800~1600 |

Packaging & Shipping

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Surface Treatment: | Baking Paint |

| Motor Type: | Frequency Control Motor |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can belt pulleys be part of HVAC systems and air conditioning units?

Yes, belt pulleys can indeed be part of HVAC (Heating, Ventilation, and Air Conditioning) systems and air conditioning units. They play a crucial role in the operation of these systems, contributing to the movement of air, power transmission, and controlling the functionality of various components. Here’s a detailed explanation of how belt pulleys are involved in HVAC systems and air conditioning units:

1. Air Handling Units: Belt pulleys are commonly used in air handling units (AHUs) of HVAC systems. AHUs are responsible for circulating and conditioning air within buildings. Belt-driven AHUs employ pulleys to drive the fans or blowers that move air through the system. The rotation of the pulleys drives the fan blades, creating airflow and facilitating the exchange of heat or coolness in the air conditioning process.

2. Cooling Towers: Cooling towers, a key component of HVAC systems, are used to remove heat from the building. Belt pulleys are employed in cooling towers to drive the fan systems that enhance the cooling process. The pulleys drive the cooling tower fans, which draw in ambient air and facilitate the evaporation of water, effectively dissipating heat and lowering the temperature of the circulated water.

3. Fan Coil Units: Fan coil units are part of HVAC systems and provide localized heating or cooling to specific areas within a building. Belt pulleys can be used in fan coil units to drive the fans that distribute conditioned air. The rotation of the pulleys drives the fan blades, enabling the movement of air through the unit and delivering heating or cooling to the desired space.

4. Compressors: In air conditioning units, belt pulleys are employed in the compressor system. The compressor is responsible for compressing the refrigerant, which enables the cooling process. Belt-driven compressors use pulleys to drive the compressor’s motor, which pressurizes the refrigerant and facilitates its movement through the air conditioning system. The pulleys ensure the efficient operation of the compressor, which is essential for the cooling function.

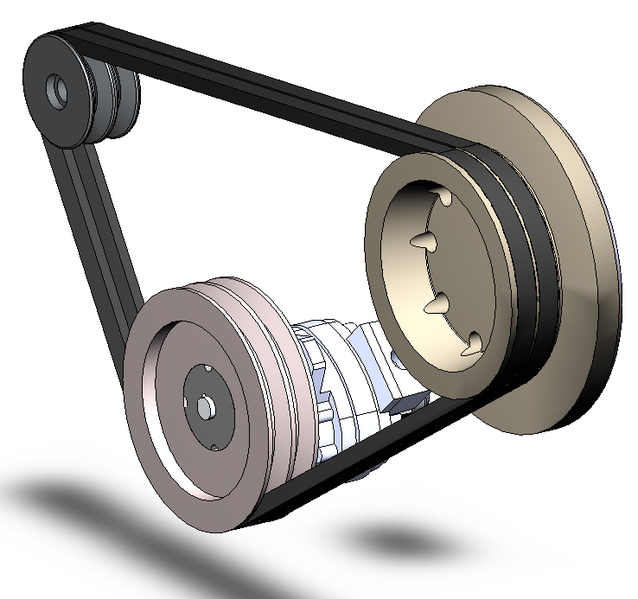

5. Power Transmission: Belt pulleys are essential for power transmission in HVAC systems and air conditioning units. They are used to transmit power from the motor or engine to various components, such as fans, compressors, pumps, and other mechanical parts. The rotation of the pulleys transfers power and enables the operation of these components, ensuring the functionality of the HVAC system or air conditioning unit.

6. Variable Speed Control: Belt pulleys can also be utilized for variable speed control in HVAC systems. By using pulleys of different sizes or incorporating variable speed pulley systems, the rotational speed of fans or other driven components can be adjusted. This allows for precise control over airflow, temperature, and overall system performance, optimizing energy efficiency and comfort levels in the building.

7. Maintenance and Serviceability: Belt pulleys in HVAC systems and air conditioning units are designed for easy maintenance and serviceability. They allow for straightforward belt replacement or adjustment, ensuring that the system can be properly maintained and serviced to maintain optimal performance and reliability.

In summary, belt pulleys are integral components of HVAC systems and air conditioning units. They are involved in power transmission, driving fans and blowers, controlling compressors, and facilitating the movement of air for heating, cooling, and ventilation. Belt pulleys contribute to the overall functionality, energy efficiency, and serviceability of HVAC systems, playing a vital role in providing comfortable and controlled environments in residential, commercial, and industrial buildings.

Can belt pulleys be used in both simple and complex mechanical systems?

Yes, belt pulleys can be used in both simple and complex mechanical systems. Belt pulleys are versatile components that are widely employed in various applications across different industries. They offer several advantages, such as reliable power transmission, flexibility in speed adjustment, and ease of installation. Here’s a detailed explanation of how belt pulleys can be utilized in both simple and complex mechanical systems:

1. Simple Mechanical Systems: Belt pulleys are commonly used in simple mechanical systems where power needs to be transmitted between two shafts. These systems typically involve straightforward power transmission requirements and relatively uncomplicated machinery. Examples of simple mechanical systems where belt pulleys are utilized include small appliances like fans or blenders, exercise equipment, and simple conveyor systems. In these cases, belt pulleys provide an efficient and cost-effective solution for transmitting power from a motor or engine to drive a specific component or perform a specific task.

2. Complex Mechanical Systems: Belt pulleys are also extensively used in complex mechanical systems that involve multiple components, intricate power transmission requirements, and advanced machinery. These systems often require precise speed control, synchronization of multiple shafts, and the ability to transmit power over long distances. Examples of complex mechanical systems where belt pulleys are employed include large-scale manufacturing machinery, printing presses, industrial robots, and automotive engine systems. In these applications, belt pulleys are crucial in achieving accurate power transmission, maintaining synchronization, and enabling efficient operation of the complex machinery.

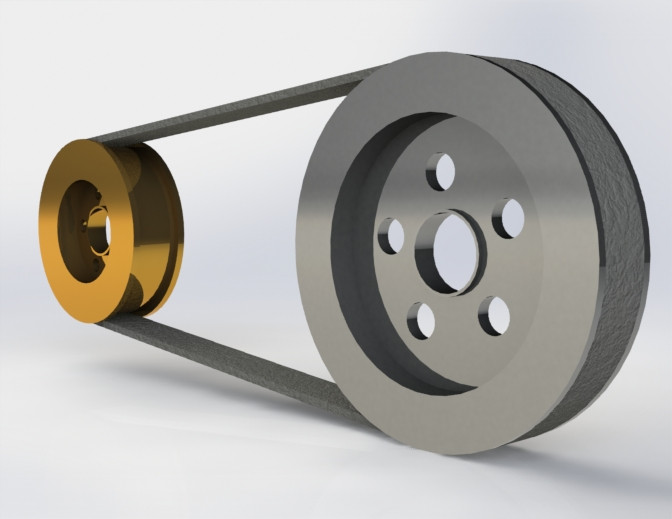

3. Speed Adjustment and Variable Power Transmission: Belt pulleys are particularly advantageous in systems that require speed adjustment or variable power transmission. By using pulleys of different sizes or adjusting the position of the belt on the pulleys, the speed and power transmission characteristics can be modified. This flexibility is beneficial in both simple and complex mechanical systems. For example, in a simple mechanical system like a drill press, a belt pulley system allows for speed adjustment to accommodate different drilling requirements. In a complex mechanical system like an assembly line, belt pulleys enable variable speed control to synchronize the movement of multiple components.

4. Adaptability and Customization: Belt pulleys can be easily adapted and customized to suit the specific requirements of both simple and complex mechanical systems. They can be designed and manufactured in various sizes, materials, and configurations to accommodate different shaft diameters, space restrictions, power transmission needs, and environmental conditions. This adaptability makes belt pulleys highly versatile components that can be integrated into diverse mechanical systems, regardless of their complexity.

5. Reliability and Maintenance: Belt pulleys offer reliable and efficient power transmission in both simple and complex mechanical systems. They have a long service life when properly installed and maintained, making them a dependable choice for various applications. Regular maintenance, such as checking for proper tension, alignment, and lubrication, ensures optimal performance and prolongs the lifespan of the belt pulleys in any mechanical system.

In summary, belt pulleys are suitable for use in both simple and complex mechanical systems. They provide efficient power transmission, speed adjustment capabilities, adaptability, and reliability. Whether it’s in a small appliance or a sophisticated industrial machine, belt pulleys play a vital role in transmitting power and enabling the smooth operation of mechanical systems across a wide range of applications and industries.

Can you explain the different types of belt pulleys and their applications?

There are several different types of belt pulleys, each designed for specific applications and requirements. The choice of pulley type depends on factors such as the power transmission needs, speed control requirements, space limitations, and the type of belt or rope used. Here’s an overview of some common types of belt pulleys and their applications:

1. V-Belt Pulleys: V-belt pulleys are one of the most widely used types of pulleys. They have a trapezoidal groove profile and are designed to accommodate V-belts, which have a corresponding cross-sectional shape. V-belt pulleys are commonly used in applications that require high torque transmission, such as in industrial machinery, automotive engines, and HVAC systems.

2. Flat Belt Pulleys: Flat belt pulleys have a flat or slightly crowned surface without any grooves. They are used with flat belts, which have a rectangular cross-section. Flat belt pulleys are suitable for applications that require high-speed power transmission, such as in textile machines, printing presses, and conveyor systems.

3. Timing Belt Pulleys: Timing belt pulleys, also known as synchronous pulleys, have teeth or grooves that mesh with the teeth of a timing belt. This design provides precise and synchronous power transmission, making them suitable for applications that require accurate positioning and timing, such as in robotics, CNC machines, and automotive engines.

4. Variable Speed Pulleys: Variable speed pulleys, also called adjustable or variable pitch pulleys, allow for continuous speed control by adjusting the effective diameter of the pulley. They feature movable pulley halves or arms that change the distance between the grooves, altering the speed ratio. Variable speed pulleys are used in applications where adjustable speed control is required, such as in machinery with variable loads or in variable speed drives.

5. Step Pulleys: Step pulleys have multiple grooves of different diameters arranged on the same pulley. By changing the belt position between these different grooves, the speed ratio can be adjusted. Step pulleys are commonly used in machines such as drill presses, lathes, and milling machines, where a range of predetermined speeds is required for different operations.

6. Idler Pulleys: Idler pulleys are not directly involved in power transmission but are used to redirect and tension the belt. They help maintain proper belt tension, improve belt wrap around the pulleys, and assist in achieving the desired belt path. Idler pulleys are commonly used in automotive engines, HVAC systems, and other belt-driven systems.

7. Clutch Pulleys: Clutch pulleys are specialized pulleys that incorporate a clutch mechanism. They allow for on-demand engagement and disengagement of the pulley from the driven shaft. Clutch pulleys are commonly used in automotive applications, such as in alternators, where they enable efficient power generation while reducing drag during idle or deceleration.

It’s important to note that these are just a few examples of belt pulley types, and there may be other specialized designs based on specific application requirements. The selection of the appropriate belt pulley type depends on factors such as the power transmission needs, speed control requirements, load capacity, and the type of belt or rope used.

In summary, different types of belt pulleys, such as V-belt pulleys, flat belt pulleys, timing belt pulleys, variable speed pulleys, step pulleys, idler pulleys, and clutch pulleys, are designed for specific applications and requirements. Understanding the characteristics and applications of these pulley types allows for the proper selection and utilization of belt pulleys in various mechanical systems.

editor by CX

2024-05-09