Product Description

|

Spec |

|

|

Polymer |

NR/SBR |

|

Density |

1.246 |

|

Hardness (Shore A) |

60±5 |

|

Tensile strength (MPA) |

14(≥14) |

|

Elongation (%) |

640(≥400) |

|

Wear (mm3) |

178(≤200) |

|

Tearing strength (N/mm) |

51 |

|

Temp (ºC) |

-40-110 |

Note: Can be produce according the client’s requirement

|

Product No. |

Thickness |

Width |

Length |

|

6832501 |

12/15/20mm |

100-500mm |

1200mm |

|

6832450 |

12/15/20mm |

100-500mm |

1450mm |

|

6832451 |

12/15/20mm |

100-500mm |

1650mm |

|

6832783 |

12/15/20mm |

100-500mm |

1850mm |

|

6832258 |

12/15/20mm |

100-500mm |

2100mm |

|

6832452 |

12/15/20mm |

100-500mm |

10m |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Natural Rubber |

|---|---|

| Usage: | Industrial |

| Feature: | Wear-resistant, Heat-resistant, Corrosion-resistant, Cold-resistant |

| Raw Materials: | Natural Rubber, Pad |

| Medium: | Pure Gum Rubber Sheet and Fabric |

| Performance: | Insulating Rubber Slab |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

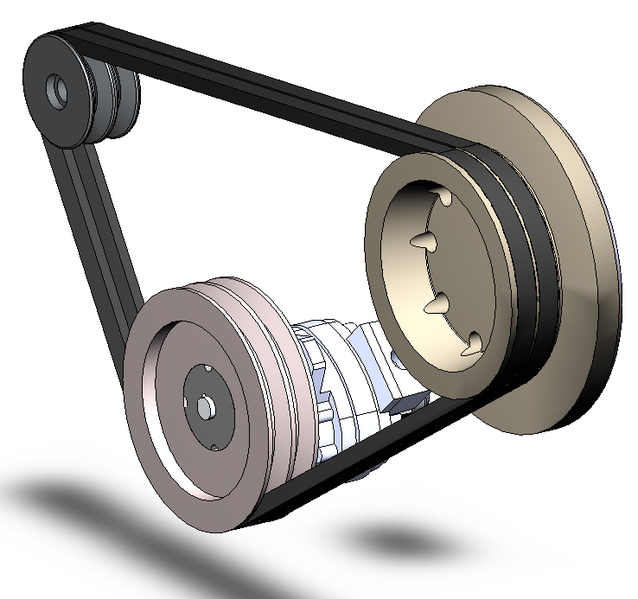

What is the role of flat belt pulleys in agricultural machinery and equipment?

Flat belt pulleys play a crucial role in agricultural machinery and equipment, contributing to various operations and functions. Here’s a detailed explanation:

1. Power Transmission:

Flat belt pulleys are commonly used in agricultural machinery to transmit power from an engine or motor to different components. They serve as driving pulleys, connecting the power source to various agricultural implements and equipment such as threshers, pumps, conveyors, and grain elevators. The efficient power transmission facilitated by flat belt pulleys enables the proper operation of these agricultural machines.

2. Belt-Driven Systems:

Many agricultural machines utilize belt-driven systems, where flat belts and pulleys are employed to transfer power. These systems are cost-effective, easy to maintain, and provide smooth power transmission. Flat belt pulleys are key components in these systems, ensuring reliable power transfer and facilitating the movement of materials or the operation of specific agricultural processes.

3. Threshing and Harvesting:

In agricultural machinery such as threshers, flat belt pulleys are integral to the threshing and harvesting process. They drive the rotating mechanisms that separate grain or seeds from the crop plants. The pulleys provide the necessary power to rotate the threshing drum or cylinder, facilitating the separation of grain or seeds from the harvested crop.

4. Irrigation and Water Pumps:

Flat belt pulleys are utilized in agricultural equipment for irrigation and water pumping applications. They drive water pumps that draw water from wells, rivers, or other sources and distribute it for irrigation purposes. The pulleys transmit power from the engine or motor to the pump, enabling efficient water pumping and irrigation operations in agricultural fields.

5. Conveyor Systems:

Agricultural conveyor systems, used for tasks such as transporting crops, seeds, or harvested produce, often incorporate flat belt pulleys. The pulleys drive the conveyor belts, facilitating the movement of agricultural materials within the farm or processing facility. These conveyor systems are crucial for efficient material handling and sorting in agricultural operations.

6. Equipment Adjustability:

Flat belt pulleys offer adjustability in agricultural machinery and equipment. By using pulleys of different sizes or adjusting the pulley positions, the speed ratios and power transmission characteristics can be modified. This adjustability allows farmers and operators to optimize the performance of agricultural machines based on specific requirements, crop conditions, or operational preferences.

7. Versatility and Durability:

Agricultural environments can be demanding, with exposure to dust, moisture, and other challenging conditions. Flat belt pulleys are designed to be versatile and durable, capable of withstanding the rigors of agricultural applications. They are often constructed from materials such as cast iron or steel, ensuring longevity and reliable performance even in harsh agricultural settings.

Overall, flat belt pulleys play a vital role in agricultural machinery and equipment by facilitating efficient power transmission, driving essential components and processes, enabling adjustability, and ensuring the smooth operation of various agricultural operations.

What types of materials are commonly used for flat belt pulley components?

Flat belt pulleys are typically composed of various materials for different components to meet specific requirements. Here’s a detailed explanation:

1. Pulley Body:

The main body of a flat belt pulley is commonly made of durable and rigid materials such as:

- Steel: Steel pulleys offer excellent strength, durability, and resistance to wear. They are commonly used in heavy-duty applications where high load capacities and long service life are required.

- Cast Iron: Cast iron pulleys are known for their high strength and resistance to wear. They are often used in industrial applications where durability and reliability are essential.

- Aluminum: Aluminum pulleys are lightweight and have good corrosion resistance. They are commonly used in applications where weight reduction is a priority or in environments where corrosion is a concern.

- Plastics: Certain types of plastics, such as nylon or polyurethane, are used in pulleys where low weight, noise reduction, or chemical resistance is required. Plastic pulleys are often used in applications that involve delicate or sensitive machinery.

2. Hub:

The hub of a flat belt pulley, which connects the pulley to the shaft, is typically made of:

- Steel: Steel hubs offer high strength and reliable connection to the shaft. They are commonly used in heavy-duty applications.

- Aluminum: Aluminum hubs are lightweight and provide good corrosion resistance. They are often used in applications where weight reduction is important.

3. Surface Coating:

To enhance the performance and durability of flat belt pulleys, surface coatings or treatments may be applied. Some common coatings include:

- Zinc or Nickel Plating: These coatings provide corrosion resistance and improve the pulley’s appearance.

- Anodizing: Anodized coatings on aluminum pulleys increase their resistance to wear and corrosion.

- Powder Coating: Powder coating provides a durable and protective layer on the pulley surface, offering improved aesthetics and resistance to corrosion, chemicals, and abrasion.

It’s important to select the appropriate materials for flat belt pulleys based on factors such as the application’s load requirements, environmental conditions, desired lifespan, and cost considerations. Consulting with pulley manufacturers or suppliers can help in determining the most suitable materials for specific pulley components.

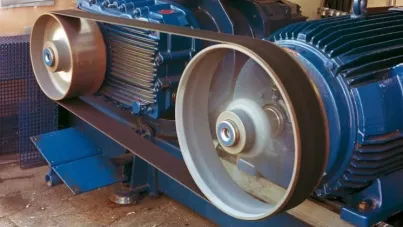

What advantages do flat belt pulleys offer for power transmission?

Flat belt pulleys offer several advantages for power transmission in various applications. Here’s a detailed explanation:

1. Simplicity:

Flat belt pulley systems are relatively simple in design and operation. They consist of a pulley and a flat belt, which are easy to install, maintain, and replace. The simplicity of the system makes it accessible and user-friendly, requiring minimal training or expertise to operate and maintain.

2. Cost-effectiveness:

Flat belt pulley systems are often cost-effective compared to other power transmission systems. The components, such as the pulleys and belts, are generally affordable and readily available. Additionally, the installation and maintenance costs are typically lower compared to more complex systems, making flat belt pulleys a cost-efficient choice for power transmission in certain applications.

3. High Speed Capability:

Flat belt pulleys can operate at high speeds, making them suitable for applications that require rapid power transmission. The flat belt design allows for smooth and efficient power transfer, reducing the risk of slippage or loss of power even at high rotational speeds.

4. Shock Absorption:

Flat belt pulleys offer good shock absorption properties due to the flexibility of the flat belt. The belt can absorb and dampen sudden shocks or vibrations, protecting the pulley system and the connected components from damage. This is particularly advantageous in applications where the machinery may experience variable or intermittent loads.

5. Compatibility:

Flat belt pulleys are compatible with a wide range of machinery and equipment. They can be easily integrated into existing systems without requiring significant modifications or adaptations. This compatibility makes flat belt pulleys a versatile choice for power transmission in various industries.

6. Misalignment Tolerance:

Flat belt pulleys can tolerate slight misalignments between the driving and driven shafts. The flexibility of the flat belt allows for some degree of deviation in alignment without affecting the overall performance or causing excessive wear on the components. This tolerance to misalignment can be beneficial in applications where precise alignment is challenging to achieve or maintain.

7. Smooth and Quiet Operation:

Flat belt pulleys provide smooth and quiet operation, contributing to a more comfortable and less noisy working environment. The flat belt design reduces vibrations and noise generated during power transmission, resulting in smoother machinery operation and reduced noise pollution.

8. Energy Efficiency:

The efficiency of power transmission in flat belt pulley systems can be quite high. With proper tensioning and adequate belt grip on the pulley, the system minimizes energy losses due to slippage or friction. This energy efficiency can lead to cost savings and improved overall equipment performance.

In summary, flat belt pulleys offer advantages such as simplicity, cost-effectiveness, high-speed capability, shock absorption, compatibility, misalignment tolerance, smooth and quiet operation, as well as energy efficiency. These advantages make flat belt pulleys suitable for various applications where these characteristics are desired or required.

editor by CX

2024-03-01