Product Description

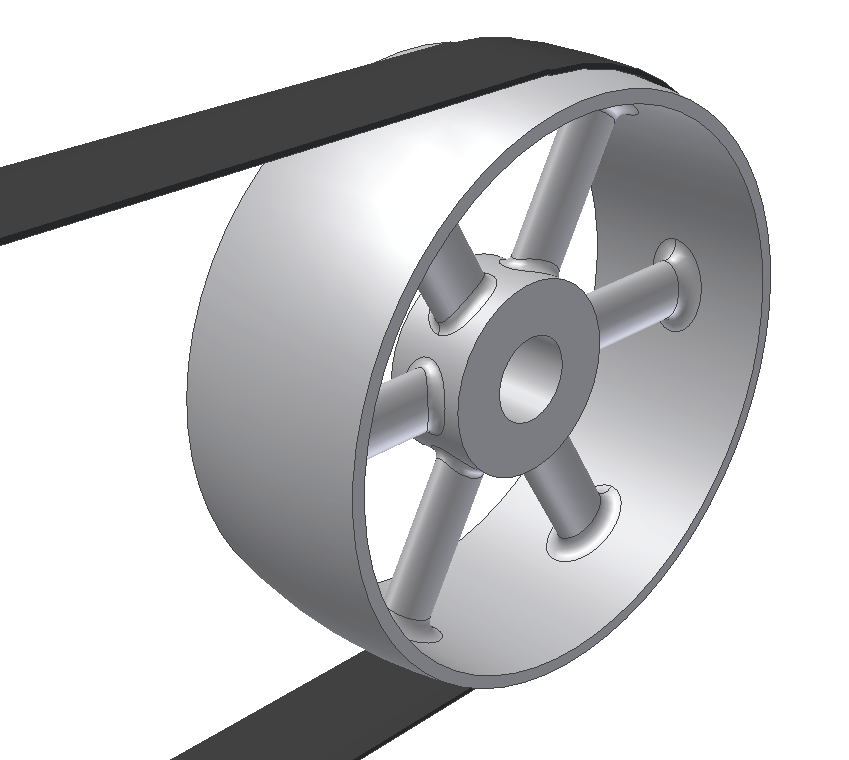

Grooved Sheave Wheel Aluminum Plastic Taper Lock Bush Idler Flat Poly V belt Adjustable Crankshaft Alternator Tension Agricultural Synchronous Timing Pulley

Timing pulley

V- belt pulley

V- belt pulley of different types ( according to type and width of belts). The material used is cast iron EN-GJL-250 CHINAMFG EN 1561, and for only a few types it is steel C45 E CHINAMFG EN 10083-1. They have a small prebore that can be machined according to customers’ requirements. Moreover the most common types are available also with taperlock bore.

V belt pulley specifications

·

European standards :

a) V-belt pulley for taper bushing: SPZ, SPA, SPB, SPC, up to 10 grooves

b) Adjustable speed V-belt pulleys and variable speed pulleys

c) Flat belt pulleys and conveyor belt pulleys

· American standard:

a) Sheaves for taper bushing: 3V, 5V, 8V

b) Sheaves for QD bushings: 3V, 5V, 8V

c) Sheaves for split taper bushing: 3V, 5V, 8V

d) Sheaves for 3L, 4L or A, and 5L or B belts: AK, AKH,2AK, 2AKH, BK, BKH,2BK, 2BKH, 3BK

e) Adjustable sheaves: poly V-pulley, multi-pitch H, L, J, K and M

· Bore: pilot bore, finish bore, taper bore, bore for QD bushing

– Parts can be made according to drawings and/or samples

· we can offer the rang size diameter 62MM~2000MM

Agricultural pulleys

If the belt pulley of your agricultural machinery is damaged or aged, you can buy a perfectly matched replacement here. Our belt pulley can adapt to the following brands:jo hn dee re, ca se-IH, Kub ota, welger, MTZ…

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type A |

| Manufacturing Process: | Casting |

| Material: | Iron |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Standards: | European American Standards |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

Can flat belt pulleys be used in both simple and complex mechanical systems?

Flat belt pulleys are versatile components that can be used in both simple and complex mechanical systems. Here’s a detailed explanation:

1. Simple Mechanical Systems:

In simple mechanical systems, flat belt pulleys are often employed for basic power transmission tasks. These systems typically involve a single pulley or a few pulleys connected by a flat belt. Simple systems may include applications such as:

- Driving conveyor belts in industrial settings

- Powering agricultural machinery

- Operating fans and blowers

- Driving pumps and compressors

- Transferring power in basic mechanical assemblies

Flat belt pulleys are well-suited for these applications due to their simplicity, ease of installation, and cost-effectiveness. They provide reliable power transmission and can handle moderate loads and speeds.

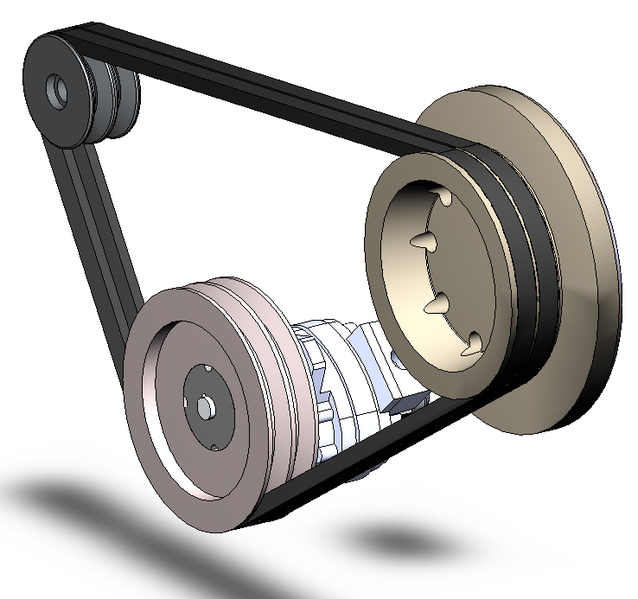

2. Complex Mechanical Systems:

In complex mechanical systems, flat belt pulleys can be integrated into more intricate setups involving multiple pulleys, shafts, and various components. These systems may have additional features such as:

- Multiple belts and pulley sets for increased power transmission capacity

- Tensioning mechanisms for maintaining proper belt tension

- Idler pulleys for belt routing and improved belt contact

- Clutches or variable speed drives for adjustable power transmission

- Overload protection mechanisms

Complex mechanical systems that utilize flat belt pulleys can be found in a wide range of industries and applications. Some examples include:

- Manufacturing and production lines

- Automotive assembly plants

- Printing and packaging machinery

- Textile manufacturing equipment

- Material handling systems

- Industrial automation systems

Flat belt pulleys in complex systems provide precise and efficient power transmission, allowing for the synchronization of multiple components and the control of various operating parameters.

Whether in simple or complex mechanical systems, flat belt pulleys offer advantages such as smooth operation, high efficiency, and the ability to transmit power over long distances. Their versatility makes them suitable for a wide range of applications, from basic setups to advanced and sophisticated machinery.

What types of materials are commonly used for flat belt pulley components?

Flat belt pulleys are typically composed of various materials for different components to meet specific requirements. Here’s a detailed explanation:

1. Pulley Body:

The main body of a flat belt pulley is commonly made of durable and rigid materials such as:

- Steel: Steel pulleys offer excellent strength, durability, and resistance to wear. They are commonly used in heavy-duty applications where high load capacities and long service life are required.

- Cast Iron: Cast iron pulleys are known for their high strength and resistance to wear. They are often used in industrial applications where durability and reliability are essential.

- Aluminum: Aluminum pulleys are lightweight and have good corrosion resistance. They are commonly used in applications where weight reduction is a priority or in environments where corrosion is a concern.

- Plastics: Certain types of plastics, such as nylon or polyurethane, are used in pulleys where low weight, noise reduction, or chemical resistance is required. Plastic pulleys are often used in applications that involve delicate or sensitive machinery.

2. Hub:

The hub of a flat belt pulley, which connects the pulley to the shaft, is typically made of:

- Steel: Steel hubs offer high strength and reliable connection to the shaft. They are commonly used in heavy-duty applications.

- Aluminum: Aluminum hubs are lightweight and provide good corrosion resistance. They are often used in applications where weight reduction is important.

3. Surface Coating:

To enhance the performance and durability of flat belt pulleys, surface coatings or treatments may be applied. Some common coatings include:

- Zinc or Nickel Plating: These coatings provide corrosion resistance and improve the pulley’s appearance.

- Anodizing: Anodized coatings on aluminum pulleys increase their resistance to wear and corrosion.

- Powder Coating: Powder coating provides a durable and protective layer on the pulley surface, offering improved aesthetics and resistance to corrosion, chemicals, and abrasion.

It’s important to select the appropriate materials for flat belt pulleys based on factors such as the application’s load requirements, environmental conditions, desired lifespan, and cost considerations. Consulting with pulley manufacturers or suppliers can help in determining the most suitable materials for specific pulley components.

How do flat belt pulleys handle variations in load capacity and speed?

Flat belt pulleys are designed to handle variations in load capacity and speed in power transmission systems. Here’s a detailed explanation:

1. Load Capacity:

Flat belt pulleys can accommodate variations in load capacity by adjusting the tension in the flat belt. Increasing the tension in the belt helps to transmit higher loads, while reducing the tension allows for lower loads. The tension can be adjusted by adjusting the position of the pulleys or by using tensioning devices such as idler pulleys or tensioning screws. By properly tensioning the belt, flat belt pulleys can efficiently transmit power and handle different load capacities.

2. Speed Variation:

Flat belt pulleys can handle variations in speed by adjusting the pulley diameters. The speed ratio between the driving pulley and the driven pulley determines the speed at which power is transmitted. By using pulleys with different diameters, the rotational speed can be adjusted accordingly. For example, a larger pulley on the driving shaft and a smaller pulley on the driven shaft will result in increased speed, while a smaller driving pulley and a larger driven pulley will reduce the speed. By selecting the appropriate pulley sizes, flat belt pulleys can accommodate different speed requirements in power transmission systems.

3. Variable Speed Pulleys:

In applications where continuous speed variation is required, variable speed pulleys can be used. These pulleys, also known as stepless or variable pitch pulleys, consist of two conical pulleys that can move axially, changing the effective diameter of the pulley. By adjusting the position of the conical pulleys, the speed ratio can be continuously varied, allowing for precise control of the transmitted speed. Variable speed pulleys are commonly used in applications such as conveyors, fans, and certain types of machinery that require adjustable speeds.

4. Belt Material Selection:

The choice of belt material can also contribute to handling variations in load capacity and speed. Different belt materials possess varying levels of strength, flexibility, and wear resistance. By selecting the appropriate belt material based on the specific application requirements, flat belt pulleys can effectively handle variations in load capacity and speed. For example, high-strength materials may be chosen for heavy-duty applications, while more flexible materials may be suitable for applications with high-speed variations.

It’s important to note that while flat belt pulleys can handle variations in load capacity and speed to a certain extent, there are practical limits based on the design and capabilities of the specific pulley system. It’s crucial to consider the manufacturer’s specifications, operating conditions, and safety factors when determining the suitable load capacity and speed requirements for a flat belt pulley system.

editor by CX

2024-03-02