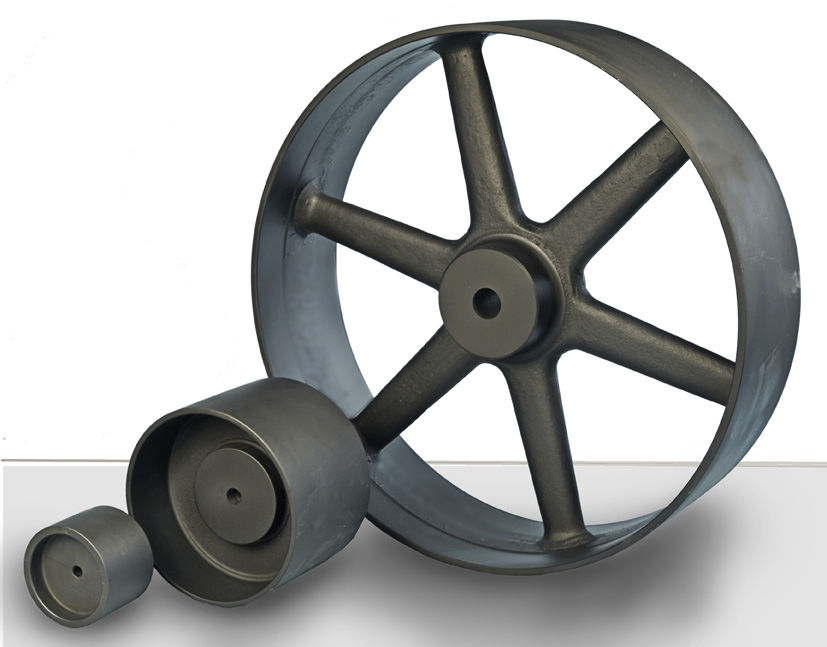

Product Description

Timing belt pulley

Teeth profile: MXL/XL/L/H/T2.5/T5/T10/AT5/AT10/HTD 3m 5m 8m 14m

Teeth Nomber: 12 ~ 144 available

Material: C45, aluminum

Surface treatment:

For C45: Black, Zinc plated, phosphated , Nature ( rust protection)

For Aluminum: anodize (clear and hard anodize)

Bore type: Pilot bore and taper bore

Our main customers:

Good quality, factory price, fast delivery!!!

For power transmission spare parts, REACH XIHU (WEST LAKE) DIS.AN will be your best choice.

Please contact me for more information:

| Certification: | ISO |

|---|---|

| Color: | Silver |

| Customized: | Customized |

| Standard: | National |

| Type: | Transmission |

| Material: | Aluminum |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How are belt pulleys utilized in the production of electronics and semiconductors?

In the production of electronics and semiconductors, belt pulleys play a crucial role in various manufacturing processes. They are utilized in different stages of production to facilitate precision, efficiency, and reliability. Here’s a detailed explanation of how belt pulleys are utilized in the production of electronics and semiconductors:

1. Conveyor Systems: Belt pulleys are commonly used in conveyor systems within electronics and semiconductor manufacturing facilities. These conveyor systems transport components, products, or wafers between different stages of production, such as assembly, testing, and packaging. Belt pulleys are utilized to drive the conveyor belts, ensuring smooth and controlled movement of the materials or products. They contribute to the efficient flow of production, allowing for continuous and automated handling of electronic components and semiconductor wafers.

2. Wafer Handling: Belt pulley systems are employed in the handling and processing of semiconductor wafers. These wafers, which serve as the base material for electronic devices, need to be transferred between various equipment and processing stations. Belt pulleys, along with precision belts, are used to grip and transport the delicate and flat wafers. The pulleys ensure accurate positioning and controlled movement of the wafers, essential for precise alignment during processes such as etching, deposition, and lithography.

3. Robotics and Automation: Belt pulleys are integral components in robotics and automation systems utilized in electronics and semiconductor production. These systems often involve robotic arms or gantries that handle and manipulate components or equipment. Belt pulleys are employed in the motorization and control mechanisms of these robotic systems, enabling precise and repeatable movements. They contribute to the accuracy, speed, and reliability required in tasks such as pick-and-place operations, soldering, and inspection processes.

4. Precision Machining: Belt pulleys are used in precision machining operations within electronics and semiconductor production. They are incorporated into milling machines, lathes, and other machining equipment that fabricate electronic components and semiconductor parts. Belt pulleys drive the cutting tools or spindles, providing the necessary rotational motion for precise material removal and shaping. The speed control and torque conversion capabilities of belt pulleys ensure the optimal performance and accuracy required for manufacturing intricate electronic and semiconductor components.

5. Testing and Inspection Equipment: Belt pulleys are utilized in testing and inspection equipment within the electronics and semiconductor industry. These machines perform various tests, measurements, and inspections to ensure the quality and functionality of electronic components and semiconductor devices. Belt pulleys drive the mechanisms that move the components or devices through different testing or inspection stations. They contribute to the controlled and synchronized movement required for accurate measurements, functional tests, and quality checks.

6. Packaging and Labeling: Belt pulleys are employed in packaging and labeling systems for electronics and semiconductor products. These systems handle the final packaging of electronic components, devices, or integrated circuits. Belt pulleys drive the conveyor belts that transport the packaged products, ensuring their smooth and efficient movement through the packaging and labeling processes. They contribute to the automated and streamlined packaging operations, allowing for high-speed production and consistent product presentation.

7. Maintenance and Serviceability: Belt pulleys contribute to the maintenance and serviceability of equipment used in electronics and semiconductor production. They are designed for easy replacement, adjustment, or inspection, allowing for quick and straightforward maintenance tasks. Properly maintained belt pulleys ensure the reliability and uptime of production equipment, minimizing downtime and optimizing the overall manufacturing process.

In summary, belt pulleys are utilized in the production of electronics and semiconductors for conveyor systems, wafer handling, robotics and automation, precision machining, testing and inspection equipment, packaging and labeling systems, as well as maintenance and serviceability. They contribute to the efficient flow of production, precise positioning of components, accurate machining, reliable testing and inspection, streamlined packaging, and ease of equipment maintenance. Belt pulleys play a vital role in enhancing the precision, efficiency, and reliability of the manufacturing processes involved in electronics and semiconductor production.

How do belt pulleys contribute to the operation of conveyor systems for material handling?

Belt pulleys play a crucial role in the operation of conveyor systems for material handling. Conveyor systems are widely used in industries such as manufacturing, mining, logistics, and agriculture to transport bulk materials or goods from one location to another. The belt pulleys in these systems contribute significantly to their functionality, efficiency, and reliability. Here’s a detailed explanation of how belt pulleys contribute to the operation of conveyor systems for material handling:

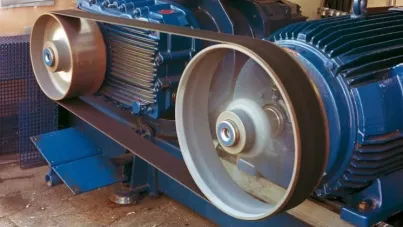

1. Power Transmission: Belt pulleys serve as the driving force for conveyor systems, transmitting power from an electric motor or engine to move the conveyor belt. The pulley is typically connected to the motor or engine shaft, and as it rotates, it drives the belt, which in turn transports the materials along the conveyor. The size and design of the pulley, along with the tension in the belt, determine the power transmission efficiency and the capacity of the conveyor system to handle different load weights and volumes.

2. Belt Tension and Tracking: Belt pulleys help maintain proper tension and tracking of the conveyor belt. Tensioning pulleys are used to adjust and maintain the tension in the belt, ensuring it remains taut and properly engaged with the pulleys. Tracking pulleys, also known as snub or bend pulleys, are strategically positioned to guide the belt and keep it centered on the pulley system. Proper tension and tracking prevent belt slippage, misalignment, and material spillage, ensuring smooth and reliable operation of the conveyor system.

3. Speed Control: Belt pulleys enable speed control in conveyor systems. By using different-sized pulleys or adjusting the pulley arrangement, the speed of the conveyor belt can be modified to suit specific material handling requirements. Speed control is essential for optimizing production processes, accommodating different material characteristics, and ensuring efficient material flow along the conveyor system.

4. Directional Changes: Belt pulleys facilitate directional changes in conveyor systems. By incorporating various pulley configurations, such as drive pulleys, idler pulleys, and bend pulleys, the conveyor belt can be guided around curves or redirected to different paths. This allows for flexible routing and layout of the conveyor system to adapt to space constraints or specific material flow patterns in material handling operations.

5. Load Distribution: Belt pulleys contribute to the even distribution of the load on the conveyor belt. As the belt wraps around the pulleys, the contact area between the belt and pulley surface spreads the load across a larger surface area. This load distribution minimizes stress concentration, reduces belt wear, and extends the operational life of the conveyor system.

6. Maintenance and Safety: Belt pulleys play a role in the maintenance and safety of conveyor systems. Accessible pulleys allow for easy inspection, cleaning, and maintenance of the conveyor belt. Pulley guards and covers provide protection against accidental contact with moving parts, enhancing the safety of personnel working around the conveyor system.

7. Customization and Adaptability: Belt pulleys can be customized and designed to meet specific material handling requirements. They can be manufactured in various sizes, materials, and configurations to accommodate different belt widths, load capacities, and environmental conditions. This customization ensures that the belt pulleys are optimized for the specific needs of the material handling application.

In summary, belt pulleys are integral components of conveyor systems for material handling. They contribute to power transmission, belt tensioning, speed control, directional changes, load distribution, and overall system maintenance and safety. By utilizing appropriately sized and designed belt pulleys, conveyor systems can efficiently and reliably transport bulk materials or goods, enhancing productivity and streamlining material handling operations in various industries.

How does a belt pulley function in power transmission?

A belt pulley plays a crucial role in power transmission by enabling the transfer of rotational motion and torque between rotating shafts. It functions as a mechanical device that connects the driving shaft to the driven shaft through a belt or a rope. The rotational motion of the driving shaft is transmitted to the driven shaft via the belt pulley, allowing power to be transferred from one shaft to another. Here’s a detailed explanation:

A belt pulley functions in power transmission through the following process:

- The driving shaft, which is typically connected to a motor or an engine, rotates and generates rotational motion and torque.

- The belt pulley is mounted on the driving shaft, and its grooved rim is designed to engage with a belt or a rope.

- A belt or a rope is wrapped around the groove of the belt pulley, creating a secure connection between the pulley and the belt.

- As the driving shaft rotates, the belt or rope, in contact with the grooved rim of the pulley, starts to move.

- The movement of the belt or rope causes the belt pulley to rotate.

- Since the belt pulley is connected to the driven shaft, which is the output shaft of the system, the rotational motion of the pulley is transferred to the driven shaft.

- Consequently, the driven shaft starts to rotate at the same speed and direction as the driving shaft.

- The rotational motion and torque generated by the driving shaft are effectively transmitted to the driven shaft through the belt pulley and the belt or rope.

It’s important to note that the design and configuration of the belt pulley, along with the belt or rope, are essential for efficient power transmission. The groove profile of the pulley should match the belt or rope profile to ensure proper engagement and prevent slippage. The tension in the belt or rope should be appropriately adjusted to maintain a secure connection between the pulley and the belt. Additionally, the size and ratio of the pulleys connected by the belt can be adjusted to control the speed and torque output, providing flexibility in power transmission.

In summary, a belt pulley functions in power transmission by connecting the driving shaft to the driven shaft through a belt or a rope. It transfers the rotational motion and torque generated by the driving shaft to the driven shaft, allowing power to be transmitted between the two shafts. The design, configuration, and tensioning of the belt and the pulley are crucial for efficient and reliable power transmission in mechanical systems.

editor by CX

2023-12-04