Product Description

Product Description

| Item No. | Door and Window Plastic Bearing Pulley |

| Dimensions | OEM ODM |

| Material | Bearing -Chrome steel, carbon steel, stainless steel Plastic part- POM/ Nylon6 /Nylon66 +GF/PU/Rubber Housing part – Plastic(Nylon)/ Steel/ Zinc alloy die casting / Aluminium profile/ alu. Alloy die casting |

| Color | Original/black/white/Red/ Green/ Orange, or per customers’ requirement |

| Surface Treatment | Zinc plated/Nickle Plated/Black treatment/ Painting/Electrophoretic treatment |

| Features | heavy-duty,adjustable,low noise,easy installation,sliding smoothly,long life,standard,customized,etc. |

| Application | Sliding window and door, Sliding accessories, furniture accessories etc. |

| Packaing | Foil bag+Neutral Carton+Pallet, or per customers’ requirement |

| MOQ | 1000 pcs |

| Lead Time | According to the order q’ty |

| OEM& ODM | Technical drawing or sample is needed |

Company Profile

ABOUT US

CHINAMFG was set up in 1996 and located at HangZhou, a beautiful city in China. Our company is bearing manufacturer&bearing distributor. Since it was first established, CHINAMFG was dedicated in research, development and manufacture of bearings. Now, CHINAMFG has become main and 1 of the first grade suppliers of all kinds of bearings. We could develop the products constructed from different materials, structures, shapes, colors etc.

WELCOME TO THE CLUB!

1. Our rollers are in stable quality with smooth rotation, long life operation, small movement, advanced injection technology engineering etc.

2. The Adjustable Rollers with smooth and long lasting operation, higher performing features like wider adjustment ranges, long rolling life performance, easy installment. It’s available in multiple housing choices with any wheels to fit different aluminnum. Our roller ensure alignment across the full adjustment ranges within built-in retention system.

3. The customized hardware, like plastic parts, stamping patrs, cold forging steel patrs are widely applied in the window and doors, furniture, householders, transmission system, industrial drive system etc.

We are constantly improving and striving for excellent service. We hold a very high regard for our customers, the quality of our products, and our level of customer service.

FAQ

1. who are we?

We are based in ZheJiang , China, start from 2017,sell to North America(1.00%),Africa(1.00%),Western Europe(1.00%),Southern Europe(1.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Bearing cage,Bearing pulley,Plastic products,Miniature bearing,Needle roller bearing

4. why should you buy from us not from other suppliers?

Hardware pulley source factory,20 years professional bearing pulley experience

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A;

Language Spoken:English,Chinese,Spanish,Japanese,F

Our Advantages

Sliding glass doors are becoming more and more popular, because of the view and natural lighting that they provide. But there can be some difficulty when it comes to maintaine them, such as the rollers have worn out. The key part is knowing which roller matches the original. Many people believe that alternatives can be found by identifying the door manufacturer individually. Actually, Most rollers are generic and used by various door manufacturers.

As the professional manufacturer of sliding rollers, we use various identifying characteristics to determine the best replacement option for your door. In addition to the number of wheels your roller uses to support the door, the presence of dimples, bumps, cut-outs and flared edges on the rollers housing will narrow down replacement options substantially. The way that the assembly installs in the door frame is also vital. The key dimensions to confirm a replacement include the width and height of the roller’s outer housing, as well as the diameter of the wheel. In addition to the diameter of the wheels, the material that they’re made of, steel or nylon, is also a factor. Long-term, metal wheels are known to hold up better but they can also cause the track to wear out faster, especially on heavy doors. Nylon wheels tend to be kinder to the track but may not last as long as their steel counterparts.

Purchase Notice

1.Pls send us an inquiry or leave us a message, there will be a dedicated staff to serve you within 1 hours.

2.You can ask us to take actual photos of the products for you, and free samples would be provided.

3. Welcome to visit our factory to negotiate orders, we will do our best to protect the safety of your business journey.

4. Packaging can be customized according to customer requirements

Finally, Please be sure to click “Contact supplier” to contact us, or “Call us” with any questions that you may have.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 45° |

|---|---|

| Aligning: | Aligning Bearing |

| Separated: | Unseparated |

| Samples: |

US$ 0.5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

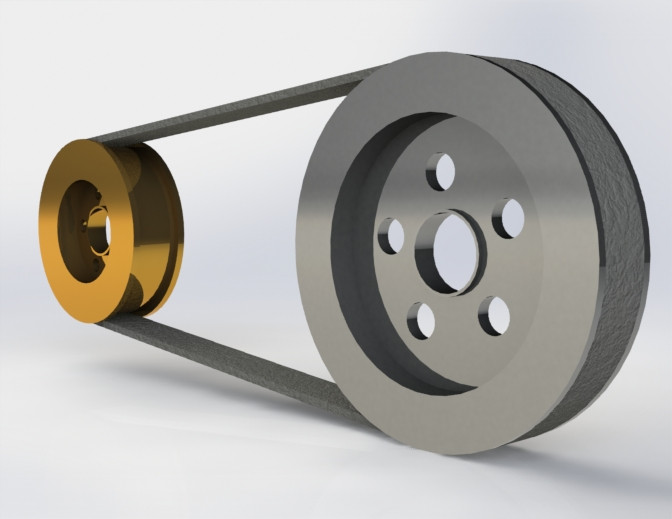

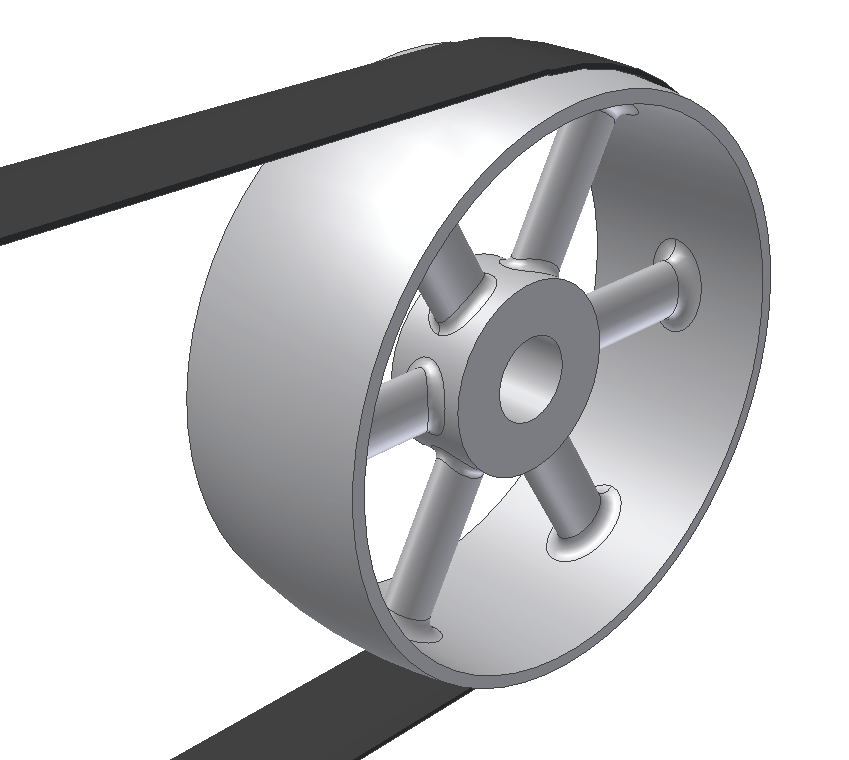

Can flat belt pulleys be used in both simple and complex mechanical systems?

Flat belt pulleys are versatile components that can be used in both simple and complex mechanical systems. Here’s a detailed explanation:

1. Simple Mechanical Systems:

In simple mechanical systems, flat belt pulleys are often employed for basic power transmission tasks. These systems typically involve a single pulley or a few pulleys connected by a flat belt. Simple systems may include applications such as:

- Driving conveyor belts in industrial settings

- Powering agricultural machinery

- Operating fans and blowers

- Driving pumps and compressors

- Transferring power in basic mechanical assemblies

Flat belt pulleys are well-suited for these applications due to their simplicity, ease of installation, and cost-effectiveness. They provide reliable power transmission and can handle moderate loads and speeds.

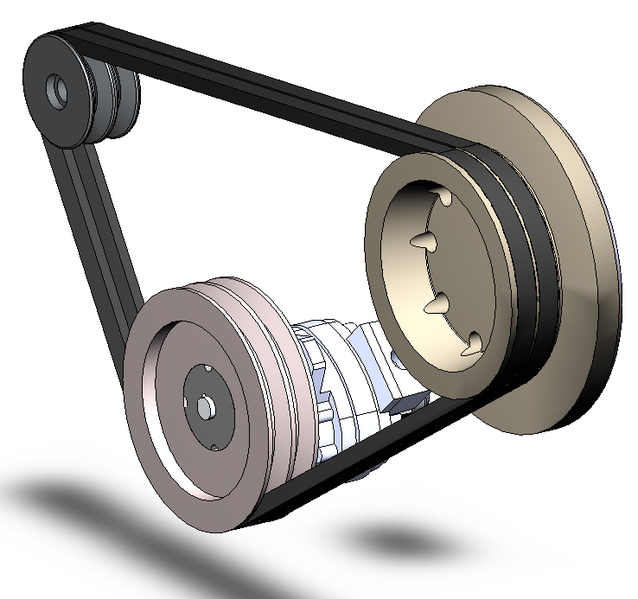

2. Complex Mechanical Systems:

In complex mechanical systems, flat belt pulleys can be integrated into more intricate setups involving multiple pulleys, shafts, and various components. These systems may have additional features such as:

- Multiple belts and pulley sets for increased power transmission capacity

- Tensioning mechanisms for maintaining proper belt tension

- Idler pulleys for belt routing and improved belt contact

- Clutches or variable speed drives for adjustable power transmission

- Overload protection mechanisms

Complex mechanical systems that utilize flat belt pulleys can be found in a wide range of industries and applications. Some examples include:

- Manufacturing and production lines

- Automotive assembly plants

- Printing and packaging machinery

- Textile manufacturing equipment

- Material handling systems

- Industrial automation systems

Flat belt pulleys in complex systems provide precise and efficient power transmission, allowing for the synchronization of multiple components and the control of various operating parameters.

Whether in simple or complex mechanical systems, flat belt pulleys offer advantages such as smooth operation, high efficiency, and the ability to transmit power over long distances. Their versatility makes them suitable for a wide range of applications, from basic setups to advanced and sophisticated machinery.

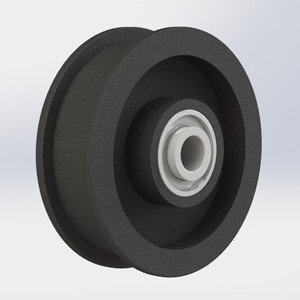

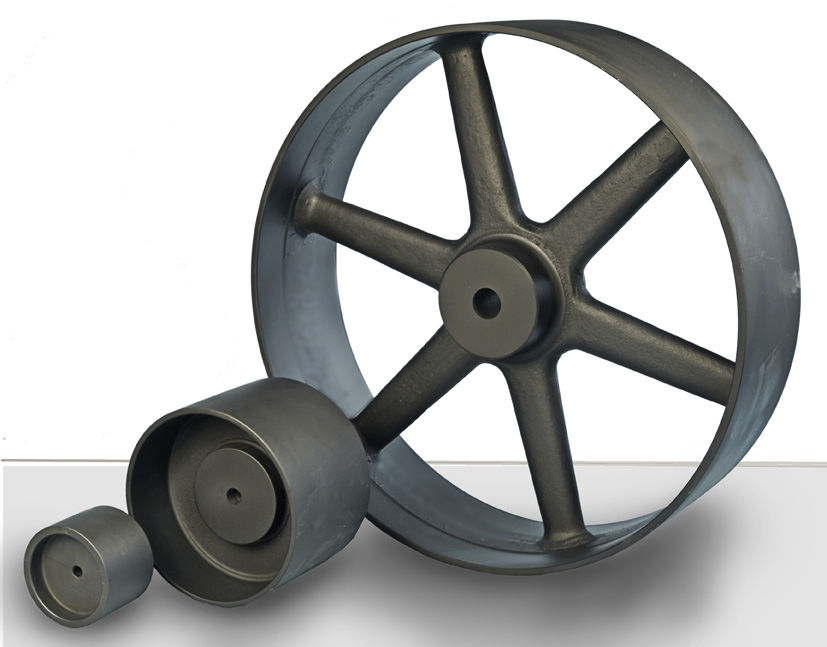

What types of materials are commonly used for flat belt pulley components?

Flat belt pulleys are typically composed of various materials for different components to meet specific requirements. Here’s a detailed explanation:

1. Pulley Body:

The main body of a flat belt pulley is commonly made of durable and rigid materials such as:

- Steel: Steel pulleys offer excellent strength, durability, and resistance to wear. They are commonly used in heavy-duty applications where high load capacities and long service life are required.

- Cast Iron: Cast iron pulleys are known for their high strength and resistance to wear. They are often used in industrial applications where durability and reliability are essential.

- Aluminum: Aluminum pulleys are lightweight and have good corrosion resistance. They are commonly used in applications where weight reduction is a priority or in environments where corrosion is a concern.

- Plastics: Certain types of plastics, such as nylon or polyurethane, are used in pulleys where low weight, noise reduction, or chemical resistance is required. Plastic pulleys are often used in applications that involve delicate or sensitive machinery.

2. Hub:

The hub of a flat belt pulley, which connects the pulley to the shaft, is typically made of:

- Steel: Steel hubs offer high strength and reliable connection to the shaft. They are commonly used in heavy-duty applications.

- Aluminum: Aluminum hubs are lightweight and provide good corrosion resistance. They are often used in applications where weight reduction is important.

3. Surface Coating:

To enhance the performance and durability of flat belt pulleys, surface coatings or treatments may be applied. Some common coatings include:

- Zinc or Nickel Plating: These coatings provide corrosion resistance and improve the pulley’s appearance.

- Anodizing: Anodized coatings on aluminum pulleys increase their resistance to wear and corrosion.

- Powder Coating: Powder coating provides a durable and protective layer on the pulley surface, offering improved aesthetics and resistance to corrosion, chemicals, and abrasion.

It’s important to select the appropriate materials for flat belt pulleys based on factors such as the application’s load requirements, environmental conditions, desired lifespan, and cost considerations. Consulting with pulley manufacturers or suppliers can help in determining the most suitable materials for specific pulley components.

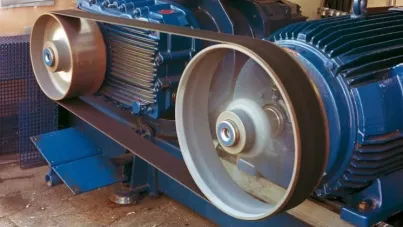

How do flat belt pulleys differ from other types of pulleys?

Flat belt pulleys have distinct characteristics that set them apart from other types of pulleys. Here’s a detailed explanation:

1. Belt Type:

The major difference lies in the type of belt used. Flat belt pulleys are specifically designed to work with flat belts, which are flexible and have a rectangular cross-section. In contrast, other types of pulleys, such as V-belt pulleys or timing belt pulleys, are designed for different belt profiles, such as V-shaped belts or toothed belts.

2. Belt Engagement:

Flat belt pulleys engage with the belt differently compared to other pulley types. The flat belt wraps around the pulley’s flat or slightly concave surface and relies on friction to transmit power. Other pulley types, like V-belt pulleys, have grooves that match the shape of the belt, providing positive engagement by fitting into the belt’s grooves.

3. Power Transmission:

Each pulley type is optimized for specific power transmission requirements. Flat belt pulleys are often used for applications that require relatively low power and moderate speeds. They are suitable for machinery that needs flexibility and ease of installation, making them commonly used in older machinery and certain industrial applications. Other pulley types, like V-belt pulleys or timing belt pulleys, offer advantages for high-power transmission, increased efficiency, or precise timing in applications such as automotive engines or industrial machinery.

4. Pulley Design:

Flat belt pulleys have a simple design, typically consisting of a cylindrical or disk-shaped body with a flat or slightly concave surface. Other pulley types may have more complex designs to accommodate specific belt profiles. For example, V-belt pulleys have grooves that match the V-shaped belts, while timing belt pulleys have toothed profiles that match the teeth on the timing belts.

5. Speed and Torque Conversion:

The design and configuration of pulleys, including flat belt pulleys, allow for speed and torque conversion. By varying the sizes of the pulleys, the speed and torque can be adjusted to meet the requirements of the machinery. However, the specific mechanisms for speed and torque conversion may differ between pulley types. For example, V-belt pulleys rely on the varying diameters of the pulleys to achieve speed conversion, while timing belt pulleys use the toothed profiles to ensure precise timing and synchronization.

6. Belt Tension and Alignment:

The methods used to maintain belt tension and alignment can also differ between pulley types. Flat belt pulleys often rely on adjustable pulley positions or tensioning mechanisms to achieve proper tension and alignment. Other pulley types may incorporate features like automatic tensioners or specialized tensioning systems to maintain optimal belt performance.

In conclusion, flat belt pulleys differ from other types of pulleys in terms of the belt type, engagement method, power transmission capabilities, design, speed and torque conversion mechanisms, as well as belt tension and alignment methods. Understanding these differences is crucial for selecting the appropriate pulley type for a given application.

editor by CX

2024-01-18