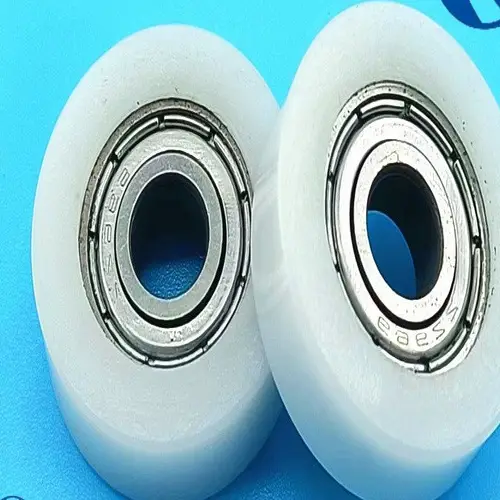

China’s Best 3D Printer and Smooth Plastic Ball Bearing Pulley with Flat Belt

Looking for the perfect plastic bearing pulley for your sliding doors and windows? Look no further than our reliable and high-quality product, made from chrome steel, carbon steel, and stainless steel. Our plastic part is constructed from POM/Nylon6/Nylon66 +GF/PU/Rubber, while our housing part is made from plastic (Nylon), steel, zinc alloy die-casting, aluminum profile, or aluminum alloy die-casting. We offer original, black, white, red, green, orange, or any other custom color you desire.

Product Features

Our sliding door and window plastic bearing pulley is designed to be heavy-duty, adjustable, low noise, easy to install, slide smoothly, and last a long time. It is also available in standard and customized sizes and shapes to suit your specific needs. Our product has gone through zinc plating, nickel plating, black treatment, painting, and electrophoretic treatment to ensure long-lasting use and durability.

Product Applications

Our product is ideal for sliding windows and doors, sliding accessories, furniture accessories, and other applications that require smooth movement, high quality, and reliability. Our pulleys are in a stable quality with smooth rotation, long life operation, small movement, advanced injection technology engineering, and wider adjustment ranges. Our roller ensures alignment across the full adjustment range with a built-in retention system.

Packaging and Shipping

We package our products in foil bags, neutral cartons, and pallets according to your requirements. Our minimum order quantity is 1000 pcs, and the lead time is according to the order quantity. We accept OEM and ODM orders and can accommodate technical drawings and sample requests.

Other Industrial Products We Offer

In addition to our plastic bearing pulleys, we also supply a variety of other industrial products, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and other mechanical components. Our products are of high quality, reasonably priced, and backed by excellent customer service. We welcome custom orders and offer quick turnaround times, so contact us today for more information!

Frequently Asked Questions

1. What materials are your plastic bearing pulleys made from?

Our plastic bearing pulleys are made from POM/Nylon6/Nylon66 +GF/PU/Rubber and are designed to be heavy-duty, adjustable, low noise, easy to install, slide smoothly, and last a long time.

2. What colors do you offer for your plastic bearing pulleys?

We offer original, black, white, red, green, orange, or any other custom color you desire.

3. What applications are your plastic bearing pulleys suitable for?

Our plastic bearing pulleys are suitable for sliding windows and doors, sliding accessories, furniture accessories, and other applications that require smooth movement, high quality, and reliability.

4. What other industrial products do you offer?

In addition to our plastic bearing pulleys, we also supply a variety of other industrial products, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and other mechanical components.

5. Do you accept custom orders?

Yes, we welcome custom orders and can accommodate technical drawings and sample requests. Contact us today for more information!

All content on this page is sourced from the Internet and is provided for reference purposes only. Our products are replacement parts and not original spare parts. We are not the holders of the original trademarks mentioned in this content. Our replacement parts are perfectly compatible with the original spare parts. If you require original spare parts, please contact the original manufacturer for purchase. If you want to buy original spare parts, please reach out to the original supplier.

Performance Characteristics of Flat Belt Pulley

Flat belt pulleys offer several performance characteristics that make them highly desirable:

- Efficient power transmission

- Smooth and quiet operation

- High load capacity

- Easy installation and maintenance

Types and Characteristics of Flat Belt Pulley

Flat belt pulleys come in various types, each with its own unique characteristics:

- Step Pulley: Allows for adjustable speed ratios

- V-Groove Pulley: Provides better traction and increased power transmission efficiency

- Flat Idler Pulley: Guides and supports the belt

Advantages of Flat Belt Pulley Materials

The material used to construct a flat belt pulley greatly impacts its performance:

- Aluminum Pulley: Lightweight, corrosion-resistant, and suitable for low-load applications

- Steel Pulley: Durable, can handle high loads, and suitable for heavy-duty applications

- Cast Iron Pulley: Robust, excellent heat dissipation, and suitable for demanding environments

Application of Flat Belt Pulley

The versatile nature of flat belt pulleys makes them indispensable in various industries:

- Agriculture: Used in machinery for crop cultivation, irrigation, and harvesting

- Automotive Industry: Used in engines, power transmission systems, and accessory drives

- Textile Industry: Used in spinning machines, looms, and other textile machinery

- Packaging Industry: Utilized in conveyor systems, labeling machines, and packaging equipment

- Printing Industry: Used in printing presses for paper feeding and ink distribution

Future Development Trends and Opportunities

Flat belt pulley products are expected to witness the following trends and opportunities:

- Increased demand for lightweight and energy-efficient pulleys

- Integration of smart technologies for improved performance monitoring

- Growing adoption of eco-friendly materials

- Expanding applications in renewable energy systems

Choosing a Suitable Flat Belt Pulley

When selecting a flat belt pulley, consider the following aspects:

- Load Capacity: Ensure the pulley can handle the required load

- Material: Choose a material that suits the application’s demands

- Diameter and Size: Select the appropriate dimensions for efficient power transmission

- Type of Pulley: Opt for the suitable pulley type based on the application’s needs

- Bore Size: Ensure compatibility with the shaft diameter

In conclusion, flat belt pulleys offer efficient power transmission, various types for different applications, and advantages based on the materials used. Their widespread use in agriculture, automotive, textile, packaging, and printing industries showcases their value and importance. The future of flat belt pulley products lies in lightweight, energy-efficient designs, integration of smart technologies, and the adoption of eco-friendly materials. By considering load capacity, material, diameter and size, type of pulley, and bore size, you can choose a suitable flat belt pulley for your specific needs.

Author: Dream