Product Description

Product Description

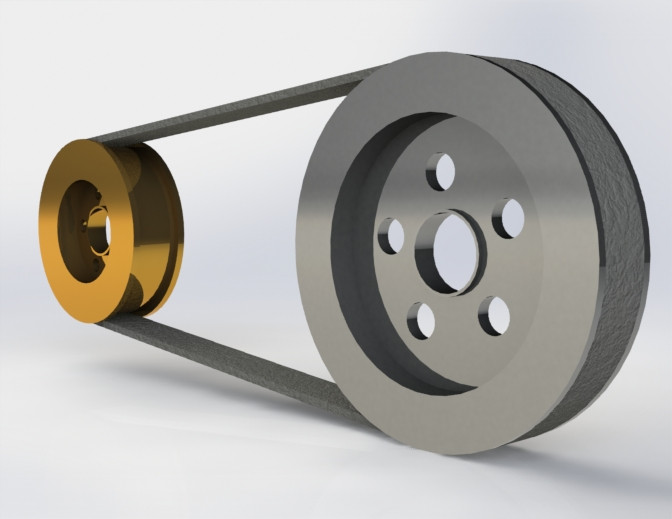

Flat belt conveyor drive drum pulley for coal mining conveyor system

Product Application

CHINAMFG conveyor pully is manufactured as per customer requirement, with main design unfer national standard, quality inspection focusing on shaft core, welded joint, rubber material and hardness, dynamic balance and so on for longer product lifetime.

Our products are widely used in thermal power generation, harbours, cement plants, metallurgy and as well as the light duty conveying devices for industries.

|

SPECIFICATIONS |

|||

|

Product name |

belt conveyor pulley drum |

||

|

Type |

Transmission drum, Redirection drum, Driving Electric drum |

||

|

Length |

200mm-1800mm |

||

|

Materials |

Carbon steel, Stainless steel, Rubber |

||

|

Surface treatment |

Smooth, CHINAMFG grooved lagging, Herringbone lagging, Ceramic lagging |

||

|

Welding |

Submerged arc welding |

||

|

Bearing |

SKF, CHINAMFG and other brands at home and abroad |

||

|

Structure |

Tube,shaft,self-aligning bearing,bearing seat/house,hub, locking bushing,end disc |

||

Main Feature

1) CHINAMFG design, suitable for heavy lifting.

2) The bearing housing and steel tube are assembled and welded with a concentric automatic.

3) Cutting of the steel tube and bearing is performed with the use of a digital auto device/machine/equipment..

4) The bearing end is constructed to ensure that the roller shaft and bearing can be firmly connected.

5) Fabrication of the roller is effected by an auto device and 100% tested for its concentricity.

6) Roller and supporting components/materials are manufactured to DIN/ AFNOR/ FEM/ ASTM/ CEMA standard.

7) The casing is manufactured with highly composite, anti corrosive alloy.

8) The roller is lubricated and free from maintenance.

9) Woring life expectancy is up to 30,000 hours or more, depending on usage.

10)Vacuum sealed which has withstood anti water, salt, snuff, sandstone and dust proof experiments

Related Products

Testing Machines

Certifications

Our Service

Our Company

Global Conveyor Supplies Co., Ltd.

Established in 1995; Land area = 20,000 m2; Staff= 120 persons.

Located in HangZhou, ZheJiang Province, next to HangZhou city.

GCS, RKM is a registered trademark in China.

GCS enjoys a renowned reputation and our products are marketed globally in South-East Asia, Middle East, Africa, Australia, Europe, Hong Kong and many other countries.

If you have any needs please feel free to contact us. Thank you!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Surface Treatment: | Oxygenation |

| Motor Type: | Frequency Control Motor |

| Installation: | Horizontal |

| Color: | Customized |

| Certification: | ISO9001-2015/SGS/GB/BV |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do flat belt pulleys affect the performance of textile manufacturing machinery?

Flat belt pulleys have a significant impact on the performance of textile manufacturing machinery. Here’s a detailed explanation:

1. Power Transmission:

Flat belt pulleys are essential for transmitting power from the motor or engine to various components within textile manufacturing machinery. They serve as driving pulleys, connecting the power source to critical machine parts, such as spindles, rollers, and looms. The efficient power transmission facilitated by flat belt pulleys ensures the smooth operation of these components, enabling the production of high-quality textiles.

2. Speed Control:

Textile manufacturing machinery often requires precise speed control for different processes, such as spinning, weaving, or knitting. Flat belt pulleys, when used in conjunction with adjustable speed drives, allow operators to control the rotational speed of the driven components. By selecting pulleys of different sizes or adjusting the pulley positions, the speed ratios can be modified, enabling optimal machine performance and ensuring the production of textiles with consistent quality.

3. Tensioning and Tracking:

Flat belts in textile manufacturing machinery need to be properly tensioned and tracked to ensure smooth and reliable operation. Flat belt pulleys are equipped with tensioning mechanisms and tracking features to maintain the appropriate belt tension and alignment. Proper tensioning and tracking, facilitated by the pulleys, prevent belt slippage, reduce wear and tear, and minimize the occurrence of defects in textile production.

4. Belt Longevity:

Flat belt pulleys, when designed and maintained correctly, contribute to the longevity of the belts used in textile manufacturing machinery. The pulleys should have smooth surfaces and edges, minimizing friction and wear on the belts. Additionally, regular inspection and maintenance of the pulleys, including checking for proper alignment and cleaning, help prevent belt damage and extend their lifespan.

5. Noise and Vibration Reduction:

Textile manufacturing machinery often operates at high speeds, leading to noise and vibration. Properly balanced and aligned flat belt pulleys help reduce these undesirable effects by ensuring smooth and stable power transmission. Minimizing noise and vibration improves the working environment for operators and helps maintain the integrity of the textile manufacturing process.

6. Maintenance and Replacement:

Flat belt pulleys in textile manufacturing machinery are relatively easy to maintain and replace. Regular inspection and lubrication of the pulleys, along with routine belt tension checks, contribute to efficient operation and prevent unexpected breakdowns. When replacement is necessary, flat belts and pulleys are readily available, minimizing downtime and optimizing overall machine performance.

7. Cost-effectiveness:

Flat belt pulleys offer a cost-effective solution for power transmission in textile manufacturing machinery. They are relatively simple in design, require minimal maintenance, and have lower initial costs compared to alternative transmission systems. The cost-effectiveness of flat belt pulleys makes them a preferred choice in the textile industry.

Overall, flat belt pulleys play a vital role in textile manufacturing machinery by ensuring efficient power transmission, enabling speed control, maintaining belt tension and tracking, enhancing belt longevity, reducing noise and vibration, facilitating maintenance and replacement, and providing a cost-effective solution. Their proper selection, installation, and maintenance are crucial for optimal performance and productivity in textile manufacturing processes.

What safety considerations should be kept in mind when working with flat belt pulleys?

Working with flat belt pulleys involves certain safety considerations to prevent accidents and ensure safe operation. Here’s a detailed explanation:

1. Machine Guarding:

It is important to ensure that flat belt pulleys are properly guarded to prevent accidental contact with rotating parts. Guards should be in place to cover the pulley and belt, minimizing the risk of entanglement or entrapment of clothing, body parts, or tools.

2. Lockout/Tagout Procedures:

Prior to performing any maintenance or servicing tasks on machinery equipped with flat belt pulleys, proper lockout/tagout procedures should be followed. This involves isolating the power source, locking out the equipment, and clearly tagging it to indicate that maintenance work is in progress. This helps to prevent inadvertent startup of the machinery, which could cause serious injuries.

3. Personal Protective Equipment (PPE):

When working with flat belt pulleys, appropriate Personal Protective Equipment (PPE) should be worn. This may include safety glasses or goggles to protect the eyes from debris or flying particles, gloves to protect hands from sharp edges or pinch points, and hearing protection if the machinery generates excessive noise.

4. Training and Education:

Operators and maintenance personnel should receive proper training and education on the safe operation and maintenance of machinery with flat belt pulleys. They should be familiar with the potential hazards associated with these systems and understand the correct procedures for installation, tensioning, and adjustment of the belts.

5. Regular Inspections and Maintenance:

Flat belt pulleys should be regularly inspected for signs of wear, damage, or misalignment. Any issues should be addressed promptly to prevent further damage or potential accidents. Routine maintenance, including belt replacement, lubrication, and tension adjustments, should be performed according to the manufacturer’s recommendations.

6. Handling Heavy Loads:

When working with machinery that utilizes flat belt pulleys for heavy load transmission, proper lifting techniques should be employed to prevent strains or injuries. Mechanical lifting aids or equipment should be used as necessary to safely handle heavy loads.

7. Risk Assessment:

A thorough risk assessment should be conducted to identify and mitigate potential hazards associated with flat belt pulleys. This includes evaluating the layout of the machinery, the positioning of pulleys and belts, and any other factors that may pose a risk to the safety of operators or maintenance personnel.

By adhering to these safety considerations, the risk of accidents or injuries when working with flat belt pulleys can be significantly reduced. It is essential to follow industry best practices, manufacturer’s guidelines, and applicable safety regulations to ensure the safe operation of machinery equipped with flat belt pulleys.

How do flat belt pulleys handle variations in load capacity and speed?

Flat belt pulleys are designed to handle variations in load capacity and speed in power transmission systems. Here’s a detailed explanation:

1. Load Capacity:

Flat belt pulleys can accommodate variations in load capacity by adjusting the tension in the flat belt. Increasing the tension in the belt helps to transmit higher loads, while reducing the tension allows for lower loads. The tension can be adjusted by adjusting the position of the pulleys or by using tensioning devices such as idler pulleys or tensioning screws. By properly tensioning the belt, flat belt pulleys can efficiently transmit power and handle different load capacities.

2. Speed Variation:

Flat belt pulleys can handle variations in speed by adjusting the pulley diameters. The speed ratio between the driving pulley and the driven pulley determines the speed at which power is transmitted. By using pulleys with different diameters, the rotational speed can be adjusted accordingly. For example, a larger pulley on the driving shaft and a smaller pulley on the driven shaft will result in increased speed, while a smaller driving pulley and a larger driven pulley will reduce the speed. By selecting the appropriate pulley sizes, flat belt pulleys can accommodate different speed requirements in power transmission systems.

3. Variable Speed Pulleys:

In applications where continuous speed variation is required, variable speed pulleys can be used. These pulleys, also known as stepless or variable pitch pulleys, consist of two conical pulleys that can move axially, changing the effective diameter of the pulley. By adjusting the position of the conical pulleys, the speed ratio can be continuously varied, allowing for precise control of the transmitted speed. Variable speed pulleys are commonly used in applications such as conveyors, fans, and certain types of machinery that require adjustable speeds.

4. Belt Material Selection:

The choice of belt material can also contribute to handling variations in load capacity and speed. Different belt materials possess varying levels of strength, flexibility, and wear resistance. By selecting the appropriate belt material based on the specific application requirements, flat belt pulleys can effectively handle variations in load capacity and speed. For example, high-strength materials may be chosen for heavy-duty applications, while more flexible materials may be suitable for applications with high-speed variations.

It’s important to note that while flat belt pulleys can handle variations in load capacity and speed to a certain extent, there are practical limits based on the design and capabilities of the specific pulley system. It’s crucial to consider the manufacturer’s specifications, operating conditions, and safety factors when determining the suitable load capacity and speed requirements for a flat belt pulley system.

editor by CX

2024-04-30