Product Description

| MIC NO. | OEM.NO | APPLICATION | YEAR | PHOTO |

| TB34FI5711 | 351241 46755714 504086751 BMW : BMW : 1128171 BMW :T.v. BMW : BMW :T.v. BMW : BMW : BMW : BMW : BMW : 1433502 BMW : 171 BMW : 1742858T.v. BMW : 1745546 BMW : 1745546T.v. BMW : 7503424 BMW : 7515864 BMW : 7515865 BMW : 7563927 FIAT : 46755714 FIAT : 504T.v. FIAT : 504086751 FIAT : 504086751T.v. IVECO : 504086751 IVECO : 504086751T.v. LAND ROVER : PQGR571 MERCEDES-BENZ : 6112T.v. MERCEDES-BENZ : 6112T.v. MERCEDES-BENZ : 6112T.v. MERCEDES-BENZ : 6112 MERCEDES-BENZ : 6462R571 TOYOTA : 1662R571T.v |

FIAT DUCATO Box (244_) 2.3 JTD FIAT DUCATO Box (250_, 290_) 110 Multijet 2,3 D FIAT DUCATO Box (250_, 290_) 120 Multijet 2,3 D FIAT DUCATO Box (250_, 290_) 120 Multijet 2,3 D 4×4 FIAT DUCATO Box (250_, 290_) 130 Multijet 2,3 D FIAT DUCATO Box (250_, 290_) 150 Multijet 2,3 D FIAT DUCATO Box (250_, 290_) 180 Multijet 2,3 D FIAT DUCATO Bus (244_) 2.3 JTD FIAT DUCATO Bus (250_, 290_) 110 Multijet 2,3 D FIAT DUCATO Bus (250_, 290_) 120 Multijet 2,3 D FIAT DUCATO Bus (250_, 290_) 130 Multijet 2,3 D FIAT DUCATO Bus (250_, 290_) 150 Multijet 2,3 D FIAT DUCATO Platform/Chassis (244_) 2.3 JTD FIAT DUCATO Platform/Chassis (250_, 290_) 110 Multijet 2,3 D FIAT DUCATO Platform/Chassis (250_, 290_) 120 Multijet 2,3 D FIAT DUCATO Platform/Chassis (250_, 290_) 120 Multijet 2,3 D 4×4 FIAT DUCATO Platform/Chassis (250_, 290_) 130 Multijet 2,3 D FIAT DUCATO Platform/Chassis (250_, 290_) 150 Multijet 2,3 D IVECO DAILY III Box Body/Estate 29 L 10 V (ALJA43A2, ALJA42A2, ALJA41A2) IVECO DAILY III Box Body/Estate 29 L 12 V (ALKA41A2, ALLA52A2, ALKA42A2) IVECO DAILY III Box Body/Estate 29 L 14 IVECO DAILY III Box Body/Estate 35 C 12 V, 35 S 12 V IVECO DAILY III Box Body/Estate 35 C 14, 35 S 14 IVECO DAILY III Box Body/Estate 35 S 10 (ANJA41A1, ANJA43A, ANJAV1A,… IVECO DAILY III Bus 35 S 12, 35 C 12, 40 C 12 IVECO DAILY III Platform/Chassis 29 L 10 (ALJAV1A1, ALJA41AA,…. IVECO DAILY III Platform/Chassis 29 L 12 (ALKA41A1, AHKA64A1, ALLA51A1) IVECO DAILY III Platform/Chassis 29 L 14 IVECO DAILY III Platform/Chassis 35 C 10 V , 35 S 10 V IVECO DAILY III Platform/Chassis 35 C 12 , 35 S 12 IVECO DAILY III Platform/Chassis 35 C 14, 35 S 14 IVECO DAILY IV Box Body/Estate 29L10 V IVECO DAILY IV Box Body/Estate 29L12 V, 29L12 V/P IVECO DAILY IV Box Body/Estate 29L14 C, 29L14 C/P, 29L14 V, 29L14 V/P IVECO DAILY IV Box Body/Estate 35C10, 35S10 IVECO DAILY IV Box Body/Estate 35C11 V, 35S11 V IVECO DAILY IV Box Body/Estate 35C12 V, 35C12 V/P, 35S12 V, 35S12 V/P IVECO DAILY IV Box Body/Estate 35C13 V, 35C13 V/P, 35S13 V, 35S13 V/P IVECO DAILY IV Box Body/Estate 35S14 C, 35S14 C/P, 35C14 V,… IVECO DAILY IV Box Body/Estate 40C10 V IVECO DAILY IV Box Body/Estate 40C11 V IVECO DAILY IV Box Body/Estate 40C12 V, 40C14 V/P IVECO DAILY IV Box Body/Estate 40C13 V, 40C13 V/P IVECO DAILY IV Bus 35S14, 35S14 /P IVECO DAILY IV Dump Truck 35C10 K IVECO DAILY IV Dump Truck 35C11 K, 35C11 DK, 35S11 K, 35S11 DK IVECO DAILY IV Dump Truck 35C12 IVECO DAILY IV Dump Truck 35C13 K, 35C13 DK, 35S13 K, 35S13 DK IVECO DAILY IV Dump Truck 35S14 K, 35S14 DK IVECO DAILY IV Platform/Chassis 29L10 IVECO DAILY IV Platform/Chassis 29L12 IVECO DAILY IV Platform/Chassis 29L14 IVECO DAILY IV Platform/Chassis 35C10, 35S10 IVECO DAILY IV Platform/Chassis 35C11, 35S11, 35S11 D, 35S11 /P IVECO DAILY IV Platform/Chassis 35C12, 35S12 IVECO DAILY IV Platform/Chassis 35C13, 35C13 /P, IVECO DAILY IV Platform/Chassis 35C14, 35S14, 35S14 /P IVECO DAILY IV Platform/Chassis 40C10 IVECO DAILY IV Platform/Chassis 40C11, 40C11 D IVECO DAILY IV Platform/Chassis 40C12 IVECO DAILY IV Platform/Chassis 40C13, 40C13 /P IVECO DAILY V Box Body/Estate 29L11 V, 35C11 V, 35S11 V, 40C11 V IVECO DAILY V Box Body/Estate 29L13 V, 35C13 V, 35S13 V, 40C13 V IVECO DAILY V Box Body/Estate 29L15 V, 35S15 V, 35C15L V, 40C15L V, IVECO DAILY V Dump Truck 35C11K, 35S11DKP IVECO DAILY V Dump Truck 35C13K, 35C13DKP IVECO DAILY V Platform/Chassis 26L11, 26L11D, 35C11D, 35S11, 40C11 IVECO DAILY V Platform/Chassis 29L13, 29L13D, 35C13D, 40C13 IVECO DAILY V Platform/Chassis 29L15 V, 35S15, 35C15L V, 40C15L V IVECO DAILY VI Box 33S11, 35S11, 35C11 IVECO DAILY VI Box 33S12, 35S12, 35C12 IVECO DAILY VI Box 33S13, 35S13, 35C13 IVECO DAILY VI Box 33S14, 35S14, 35C14 IVECO DAILY VI Box 33S15, 35S15, 35C15 IVECO DAILY VI Box 33S16, 35S16, 35C16 IVECO DAILY VI Box Body/Estate 33S12, 35S12 IVECO DAILY VI Box Body/Estate 33S14, 35S14 IVECO DAILY VI Box Body/Estate 33S16, 35S16 IVECO DAILY VI Platform/Chassis 33S11, 35S11, 35C11 IVECO DAILY VI Platform/Chassis 33S12, 35S12, 35C12 IVECO DAILY VI Platform/Chassis 33S13, 35S13, 35C13 IVECO DAILY VI Platform/Chassis 33S14, 35S14, 35C14 IVECO DAILY VI Platform/Chassis 33S15, 35S15, 35C15 IVECO DAILY VI Platform/Chassis 33S16, 35S16, 35C16 |

2002- 2011- 2006- 2571- 2011- 2011- 2015- 2002- 2011- 2006- 2011- 2011- 2002-2006 2011- 2006- 2571- 2006- 2011- 2002-2007 2002-2007 2005-2006 2002-2007 2005-2006 2002-2007 2003-2006 2002-2006 2002-2006 2005-2006 2002-2006 2002-2006 2005-2006 2006-2011 2006-2011 2006-2011 2006-2011 2007-2011 2006-2011 2007-2011 2006-2011 2006-2011 2007-2011 2006-2011 2007-2011 2006-2011 2006-2011 2007-2011 2006-2011 2007-2011 2007-2011 2006-2011 2006-2011 2006-2011 2006-2011 2007-2011 2006-2011 2007-2011 2006-2011 2006-2011 2007-2011 2006-2011 2007-2011 2011-2014 2011-2014 2011-2014 2011-2014 2011-2014 2011-2014 2011-2014 2011-2014 2014-2016 2016- 2014-2016 2016- 2014-2016 2016- 2016- 2016- 2016- 2014-2016 2016- 2014-2016 2016- 2014-2016 2016- |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Technical Support |

|---|---|

| Warranty: | One Year |

| Car Make: | FLAT |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

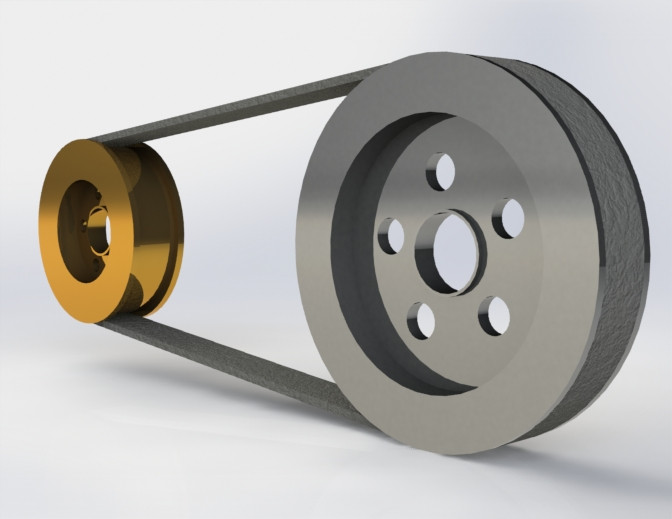

How do flat belt pulleys affect the performance of textile manufacturing machinery?

Flat belt pulleys have a significant impact on the performance of textile manufacturing machinery. Here’s a detailed explanation:

1. Power Transmission:

Flat belt pulleys are essential for transmitting power from the motor or engine to various components within textile manufacturing machinery. They serve as driving pulleys, connecting the power source to critical machine parts, such as spindles, rollers, and looms. The efficient power transmission facilitated by flat belt pulleys ensures the smooth operation of these components, enabling the production of high-quality textiles.

2. Speed Control:

Textile manufacturing machinery often requires precise speed control for different processes, such as spinning, weaving, or knitting. Flat belt pulleys, when used in conjunction with adjustable speed drives, allow operators to control the rotational speed of the driven components. By selecting pulleys of different sizes or adjusting the pulley positions, the speed ratios can be modified, enabling optimal machine performance and ensuring the production of textiles with consistent quality.

3. Tensioning and Tracking:

Flat belts in textile manufacturing machinery need to be properly tensioned and tracked to ensure smooth and reliable operation. Flat belt pulleys are equipped with tensioning mechanisms and tracking features to maintain the appropriate belt tension and alignment. Proper tensioning and tracking, facilitated by the pulleys, prevent belt slippage, reduce wear and tear, and minimize the occurrence of defects in textile production.

4. Belt Longevity:

Flat belt pulleys, when designed and maintained correctly, contribute to the longevity of the belts used in textile manufacturing machinery. The pulleys should have smooth surfaces and edges, minimizing friction and wear on the belts. Additionally, regular inspection and maintenance of the pulleys, including checking for proper alignment and cleaning, help prevent belt damage and extend their lifespan.

5. Noise and Vibration Reduction:

Textile manufacturing machinery often operates at high speeds, leading to noise and vibration. Properly balanced and aligned flat belt pulleys help reduce these undesirable effects by ensuring smooth and stable power transmission. Minimizing noise and vibration improves the working environment for operators and helps maintain the integrity of the textile manufacturing process.

6. Maintenance and Replacement:

Flat belt pulleys in textile manufacturing machinery are relatively easy to maintain and replace. Regular inspection and lubrication of the pulleys, along with routine belt tension checks, contribute to efficient operation and prevent unexpected breakdowns. When replacement is necessary, flat belts and pulleys are readily available, minimizing downtime and optimizing overall machine performance.

7. Cost-effectiveness:

Flat belt pulleys offer a cost-effective solution for power transmission in textile manufacturing machinery. They are relatively simple in design, require minimal maintenance, and have lower initial costs compared to alternative transmission systems. The cost-effectiveness of flat belt pulleys makes them a preferred choice in the textile industry.

Overall, flat belt pulleys play a vital role in textile manufacturing machinery by ensuring efficient power transmission, enabling speed control, maintaining belt tension and tracking, enhancing belt longevity, reducing noise and vibration, facilitating maintenance and replacement, and providing a cost-effective solution. Their proper selection, installation, and maintenance are crucial for optimal performance and productivity in textile manufacturing processes.

How do flat belt pulleys handle different belt sizes and materials?

Flat belt pulleys are designed to accommodate different belt sizes and materials to ensure efficient power transmission. Here’s a detailed explanation:

1. Belt Sizes:

Flat belt pulleys are available in various sizes to match different belt widths and thicknesses. The width of the pulley’s groove is designed to provide proper contact and grip with the belt. Pulleys with wider grooves are used for wider belts, while narrower grooves are used for narrower belts. The pulley’s diameter may also vary depending on the specific application and power requirements.

2. Belt Materials:

Flat belt pulleys can handle a wide range of belt materials, including:

- Rubber: Rubber belts are commonly used due to their flexibility, high friction coefficient, and resistance to wear. They provide good grip and are suitable for most general-purpose applications.

- Polyurethane: Polyurethane belts offer high resistance to abrasion, oil, and chemicals. They are often used in applications that require superior performance and durability.

- Leather: Leather belts are known for their high strength and flexibility. They are used in applications where a certain level of slip is required or to transmit power in antique or vintage machinery.

- Nylon: Nylon belts are lightweight, have high tensile strength, and offer good resistance to wear and moisture. They are commonly used in applications that require low noise and high load capacity.

3. Belt Tensioning:

Flat belt pulleys should be designed with a tensioning mechanism to accommodate different belt sizes and maintain proper tension. This mechanism, such as an idler pulley or tensioning screw, allows for easy adjustment of the belt tension to ensure optimal power transmission and prevent slippage.

4. Belt Tracking:

To handle different belt sizes and materials, flat belt pulleys should be designed to provide proper belt tracking. This ensures that the belt stays within the pulley’s groove and maintains alignment during operation. Proper flanges or guides are often incorporated into the pulley design to prevent the belt from slipping off or wandering.

5. Material Compatibility:

The materials used in flat belt pulleys should be selected to be compatible with the specific belt materials. For example, if using a rubber belt, the pulley material should not cause excessive wear or damage to the belt’s surface. Compatibility between the pulley and the belt material helps ensure optimal performance and longevity.

By considering these factors, flat belt pulleys can effectively handle different belt sizes and materials, providing reliable power transmission in a wide range of applications.

How do flat belt pulleys handle variations in load capacity and speed?

Flat belt pulleys are designed to handle variations in load capacity and speed in power transmission systems. Here’s a detailed explanation:

1. Load Capacity:

Flat belt pulleys can accommodate variations in load capacity by adjusting the tension in the flat belt. Increasing the tension in the belt helps to transmit higher loads, while reducing the tension allows for lower loads. The tension can be adjusted by adjusting the position of the pulleys or by using tensioning devices such as idler pulleys or tensioning screws. By properly tensioning the belt, flat belt pulleys can efficiently transmit power and handle different load capacities.

2. Speed Variation:

Flat belt pulleys can handle variations in speed by adjusting the pulley diameters. The speed ratio between the driving pulley and the driven pulley determines the speed at which power is transmitted. By using pulleys with different diameters, the rotational speed can be adjusted accordingly. For example, a larger pulley on the driving shaft and a smaller pulley on the driven shaft will result in increased speed, while a smaller driving pulley and a larger driven pulley will reduce the speed. By selecting the appropriate pulley sizes, flat belt pulleys can accommodate different speed requirements in power transmission systems.

3. Variable Speed Pulleys:

In applications where continuous speed variation is required, variable speed pulleys can be used. These pulleys, also known as stepless or variable pitch pulleys, consist of two conical pulleys that can move axially, changing the effective diameter of the pulley. By adjusting the position of the conical pulleys, the speed ratio can be continuously varied, allowing for precise control of the transmitted speed. Variable speed pulleys are commonly used in applications such as conveyors, fans, and certain types of machinery that require adjustable speeds.

4. Belt Material Selection:

The choice of belt material can also contribute to handling variations in load capacity and speed. Different belt materials possess varying levels of strength, flexibility, and wear resistance. By selecting the appropriate belt material based on the specific application requirements, flat belt pulleys can effectively handle variations in load capacity and speed. For example, high-strength materials may be chosen for heavy-duty applications, while more flexible materials may be suitable for applications with high-speed variations.

It’s important to note that while flat belt pulleys can handle variations in load capacity and speed to a certain extent, there are practical limits based on the design and capabilities of the specific pulley system. It’s crucial to consider the manufacturer’s specifications, operating conditions, and safety factors when determining the suitable load capacity and speed requirements for a flat belt pulley system.

editor by CX

2024-03-12