Product Description

Product Description

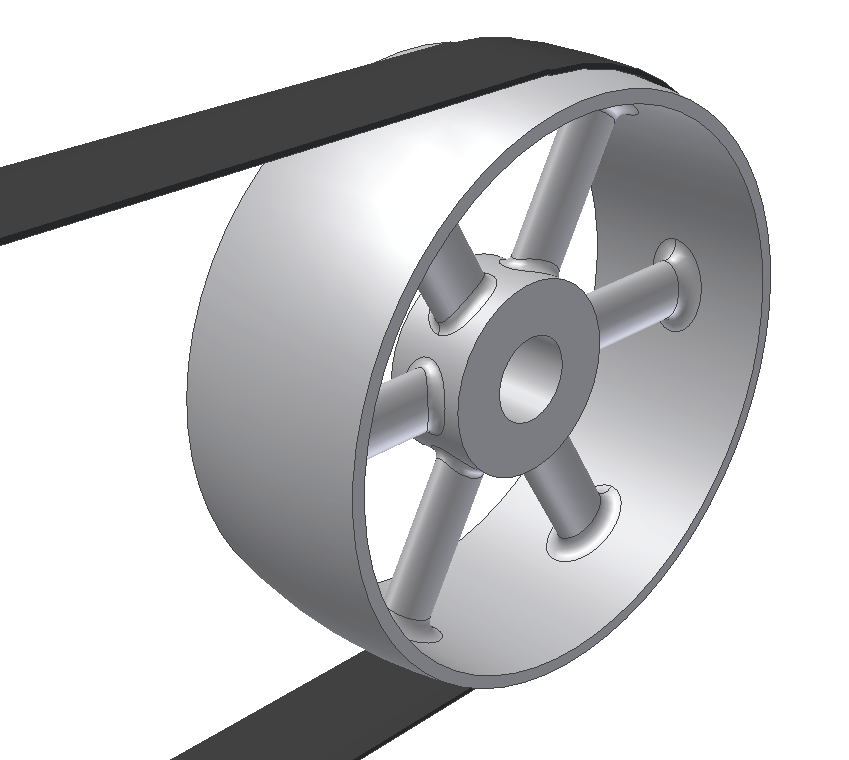

Flat belt conveyor drive drum pulley for coal mining conveyor system

Product Application

CHINAMFG conveyor pully is manufactured as per customer requirement, with main design unfer national standard, quality inspection focusing on shaft core, welded joint, rubber material and hardness, dynamic balance and so on for longer product lifetime.

Our products are widely used in thermal power generation, harbours, cement plants, metallurgy and as well as the light duty conveying devices for industries.

|

SPECIFICATIONS |

|||

|

Product name |

belt conveyor pulley drum |

||

|

Type |

Transmission drum, Redirection drum, Driving Electric drum |

||

|

Length |

200mm-1800mm |

||

|

Materials |

Carbon steel, Stainless steel, Rubber |

||

|

Surface treatment |

Smooth, CHINAMFG grooved lagging, Herringbone lagging, Ceramic lagging |

||

|

Welding |

Submerged arc welding |

||

|

Bearing |

SKF, CHINAMFG and other brands at home and abroad |

||

|

Structure |

Tube,shaft,self-aligning bearing,bearing seat/house,hub, locking bushing,end disc |

||

Main Feature

1) CHINAMFG design, suitable for heavy lifting.

2) The bearing housing and steel tube are assembled and welded with a concentric automatic.

3) Cutting of the steel tube and bearing is performed with the use of a digital auto device/machine/equipment..

4) The bearing end is constructed to ensure that the roller shaft and bearing can be firmly connected.

5) Fabrication of the roller is effected by an auto device and 100% tested for its concentricity.

6) Roller and supporting components/materials are manufactured to DIN/ AFNOR/ FEM/ ASTM/ CEMA standard.

7) The casing is manufactured with highly composite, anti corrosive alloy.

8) The roller is lubricated and free from maintenance.

9) Woring life expectancy is up to 30,000 hours or more, depending on usage.

10)Vacuum sealed which has withstood anti water, salt, snuff, sandstone and dust proof experiments

Related Products

Testing Machines

Certifications

Our Service

Our Company

Global Conveyor Supplies Co., Ltd.

Established in 1995; Land area = 20,000 m2; Staff= 120 persons.

Located in HangZhou, ZheJiang Province, next to HangZhou city.

GCS, RKM is a registered trademark in China.

GCS enjoys a renowned reputation and our products are marketed globally in South-East Asia, Middle East, Africa, Australia, Europe, Hong Kong and many other countries.

If you have any needs please feel free to contact us. Thank you!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Surface Treatment: | Oxygenation |

| Motor Type: | Frequency Control Motor |

| Installation: | Horizontal |

| Color: | Customized |

| Certification: | ISO9001-2015/SGS/GB/BV |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

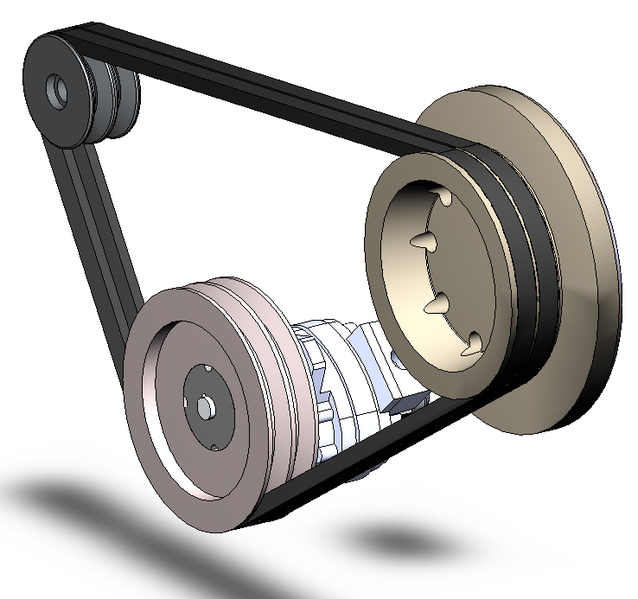

Can flat belt pulleys be used in both simple and complex mechanical systems?

Flat belt pulleys are versatile components that can be used in both simple and complex mechanical systems. Here’s a detailed explanation:

1. Simple Mechanical Systems:

In simple mechanical systems, flat belt pulleys are often employed for basic power transmission tasks. These systems typically involve a single pulley or a few pulleys connected by a flat belt. Simple systems may include applications such as:

- Driving conveyor belts in industrial settings

- Powering agricultural machinery

- Operating fans and blowers

- Driving pumps and compressors

- Transferring power in basic mechanical assemblies

Flat belt pulleys are well-suited for these applications due to their simplicity, ease of installation, and cost-effectiveness. They provide reliable power transmission and can handle moderate loads and speeds.

2. Complex Mechanical Systems:

In complex mechanical systems, flat belt pulleys can be integrated into more intricate setups involving multiple pulleys, shafts, and various components. These systems may have additional features such as:

- Multiple belts and pulley sets for increased power transmission capacity

- Tensioning mechanisms for maintaining proper belt tension

- Idler pulleys for belt routing and improved belt contact

- Clutches or variable speed drives for adjustable power transmission

- Overload protection mechanisms

Complex mechanical systems that utilize flat belt pulleys can be found in a wide range of industries and applications. Some examples include:

- Manufacturing and production lines

- Automotive assembly plants

- Printing and packaging machinery

- Textile manufacturing equipment

- Material handling systems

- Industrial automation systems

Flat belt pulleys in complex systems provide precise and efficient power transmission, allowing for the synchronization of multiple components and the control of various operating parameters.

Whether in simple or complex mechanical systems, flat belt pulleys offer advantages such as smooth operation, high efficiency, and the ability to transmit power over long distances. Their versatility makes them suitable for a wide range of applications, from basic setups to advanced and sophisticated machinery.

What types of materials are commonly used for flat belt pulley components?

Flat belt pulleys are typically composed of various materials for different components to meet specific requirements. Here’s a detailed explanation:

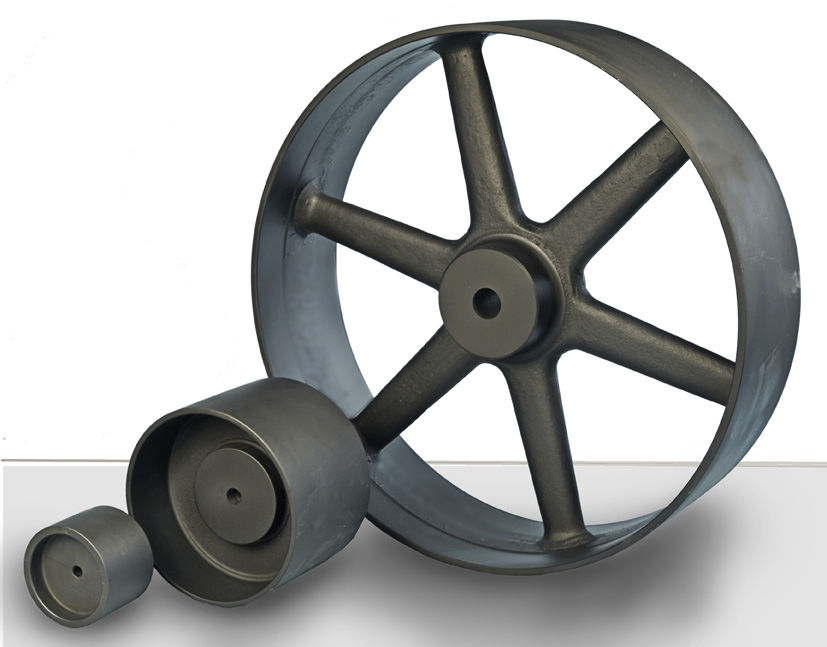

1. Pulley Body:

The main body of a flat belt pulley is commonly made of durable and rigid materials such as:

- Steel: Steel pulleys offer excellent strength, durability, and resistance to wear. They are commonly used in heavy-duty applications where high load capacities and long service life are required.

- Cast Iron: Cast iron pulleys are known for their high strength and resistance to wear. They are often used in industrial applications where durability and reliability are essential.

- Aluminum: Aluminum pulleys are lightweight and have good corrosion resistance. They are commonly used in applications where weight reduction is a priority or in environments where corrosion is a concern.

- Plastics: Certain types of plastics, such as nylon or polyurethane, are used in pulleys where low weight, noise reduction, or chemical resistance is required. Plastic pulleys are often used in applications that involve delicate or sensitive machinery.

2. Hub:

The hub of a flat belt pulley, which connects the pulley to the shaft, is typically made of:

- Steel: Steel hubs offer high strength and reliable connection to the shaft. They are commonly used in heavy-duty applications.

- Aluminum: Aluminum hubs are lightweight and provide good corrosion resistance. They are often used in applications where weight reduction is important.

3. Surface Coating:

To enhance the performance and durability of flat belt pulleys, surface coatings or treatments may be applied. Some common coatings include:

- Zinc or Nickel Plating: These coatings provide corrosion resistance and improve the pulley’s appearance.

- Anodizing: Anodized coatings on aluminum pulleys increase their resistance to wear and corrosion.

- Powder Coating: Powder coating provides a durable and protective layer on the pulley surface, offering improved aesthetics and resistance to corrosion, chemicals, and abrasion.

It’s important to select the appropriate materials for flat belt pulleys based on factors such as the application’s load requirements, environmental conditions, desired lifespan, and cost considerations. Consulting with pulley manufacturers or suppliers can help in determining the most suitable materials for specific pulley components.

What are the key components and design features of a flat belt pulley?

A flat belt pulley consists of several key components and design features that enable its functionality. Here’s a detailed explanation:

1. Pulley Body:

The pulley body forms the main structure of the flat belt pulley. It is typically cylindrical or disk-shaped and is made of durable materials such as cast iron, steel, or aluminum. The pulley body provides the foundation for the other components and supports the flat belt during operation.

2. Pulley Surface:

The surface of a flat belt pulley is designed to accommodate the flat belt. It may be flat or slightly concave to enhance belt contact and improve power transmission efficiency. The surface finish is chosen to optimize friction and traction between the pulley and the flat belt, reducing slippage and ensuring reliable power transfer.

3. Belt Grooves:

Some flat belt pulleys feature grooves or channels on their surface to accommodate the flat belt. These grooves provide a secure fit for the belt, preventing it from slipping or coming off the pulley during operation. The number and configuration of the grooves may vary depending on the specific application and belt requirements.

4. Hub or Bore:

The hub or bore is the central opening in the pulley body that allows the pulley to be mounted on a shaft. It is typically cylindrical and matches the diameter of the shaft. The hub may have keyways, set screws, or other mechanisms to ensure a secure and precise connection between the pulley and the shaft.

5. Keyway:

A keyway is a slot or groove machined into the bore of the flat belt pulley. It is used to accommodate a key, which is a small, rectangular metal piece. The key prevents the pulley from rotating independently on the shaft by providing a positive engagement between the pulley and the shaft.

6. Set Screws or Locking Mechanisms:

In addition to or instead of a keyway, flat belt pulleys may incorporate set screws or other locking mechanisms to secure the pulley to the shaft. These mechanisms allow for easy installation and removal of the pulley while ensuring it remains firmly in place during operation.

7. Balance and Alignment Features:

Flat belt pulleys are often balanced and aligned to minimize vibration and ensure smooth operation. Imbalances can lead to increased wear on the belt, bearings, and other components, as well as contribute to noise and reduced performance. Balancing techniques, such as counterweights or precision machining, are employed to achieve optimal balance. Additionally, pulleys may incorporate features like crowned surfaces or tracking guides to aid in belt alignment, reducing the risk of misalignment and optimizing power transmission.

8. Protective Coatings or Finishes:

To enhance durability and corrosion resistance, flat belt pulleys may be coated with protective finishes or coatings. These coatings, such as paint, powder coating, or specialized treatments, help protect the pulley from environmental factors, moisture, and wear, extending its service life.

In summary, the key components and design features of a flat belt pulley include the pulley body, pulley surface, belt grooves, hub or bore, keyway, set screws or locking mechanisms, balance and alignment features, as well as protective coatings or finishes. These elements work together to ensure efficient power transmission and reliable operation in machinery.

editor by CX

2024-03-07