Product Description

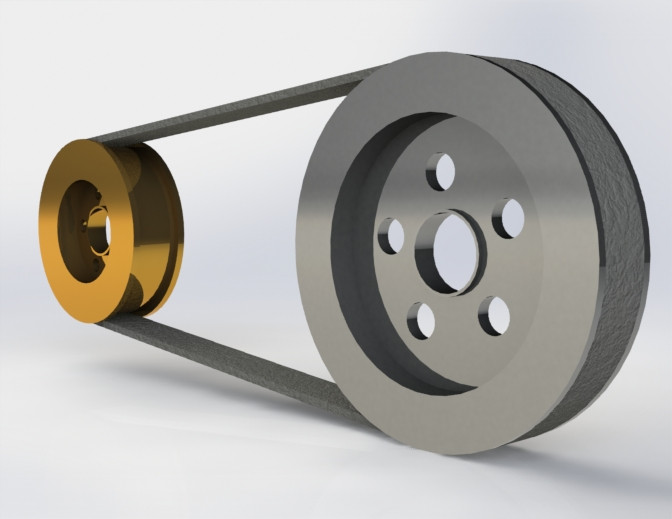

Custom Flat Nylon Plastic Pulley / Wire Rope Conveyor Head Pulley / Small Mini Belt Pulley

Products Type

We can custom shape,size,color material and quantity for plastic pulley as your requirment.

Products Specification

1. Various hardness for your choice.

2. Good abrasion, heat and oil resistance.

3. Good anti-aging performance and gas tightness.

4. Ease of bonding to other material.

5. Excellent oxygen and CHINAMFG resistance.

6. Non-flammable,self-extinguish.

| Material | PA,PA6,PA66,PP,PE,LDPE,HDPE,UWHDPE,PTFE,POM,ABS,or Custom Compound (Any custom compound plastic is available) |

| Size | According to samples or drawings |

| Color | Black,white,red,green,transparent or any color according to Pantone colors |

| Finish | High Gloss,Fine Grain,Electroplating,Painting,Printing,Texture etc,or as request |

| Type | Round,square,rectangular,or any nonstandard shape as request |

| Logo | Debossed,embossed,printed logo or as request |

Plastic Material Properties

Company Profile

Zhongde (ZheJiang ) Machinery Equipment Co.,LTD is a company integrated in design,OEM&ODM plastic&rubber&CNCparts production.We can provide the best products and service at a competitive price.

Main Products

We can provide OEM service,which means producing base on your drawings or samples,also we can design according to its application or customer`s requirments.

Order Operation Flow

We execute each step according to the operation process flow, strictly, seriously and meet the requirements of customers with good quality on time.

For Fast Quotation,Please Inform Below Details

1. Production type

2. Material specification (or let us know the using environmental)

3. Size details? (or provide drawings or samples for refference)

4. Quantity request

5. Prefer color /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Customized |

|---|---|

| Color: | Customized |

| Type: | Rotating Wheel |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | Order Sample For sample price, package information, and logisti

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do flat belt pulleys affect the performance of textile manufacturing machinery?

Flat belt pulleys have a significant impact on the performance of textile manufacturing machinery. Here’s a detailed explanation:

1. Power Transmission:

Flat belt pulleys are essential for transmitting power from the motor or engine to various components within textile manufacturing machinery. They serve as driving pulleys, connecting the power source to critical machine parts, such as spindles, rollers, and looms. The efficient power transmission facilitated by flat belt pulleys ensures the smooth operation of these components, enabling the production of high-quality textiles.

2. Speed Control:

Textile manufacturing machinery often requires precise speed control for different processes, such as spinning, weaving, or knitting. Flat belt pulleys, when used in conjunction with adjustable speed drives, allow operators to control the rotational speed of the driven components. By selecting pulleys of different sizes or adjusting the pulley positions, the speed ratios can be modified, enabling optimal machine performance and ensuring the production of textiles with consistent quality.

3. Tensioning and Tracking:

Flat belts in textile manufacturing machinery need to be properly tensioned and tracked to ensure smooth and reliable operation. Flat belt pulleys are equipped with tensioning mechanisms and tracking features to maintain the appropriate belt tension and alignment. Proper tensioning and tracking, facilitated by the pulleys, prevent belt slippage, reduce wear and tear, and minimize the occurrence of defects in textile production.

4. Belt Longevity:

Flat belt pulleys, when designed and maintained correctly, contribute to the longevity of the belts used in textile manufacturing machinery. The pulleys should have smooth surfaces and edges, minimizing friction and wear on the belts. Additionally, regular inspection and maintenance of the pulleys, including checking for proper alignment and cleaning, help prevent belt damage and extend their lifespan.

5. Noise and Vibration Reduction:

Textile manufacturing machinery often operates at high speeds, leading to noise and vibration. Properly balanced and aligned flat belt pulleys help reduce these undesirable effects by ensuring smooth and stable power transmission. Minimizing noise and vibration improves the working environment for operators and helps maintain the integrity of the textile manufacturing process.

6. Maintenance and Replacement:

Flat belt pulleys in textile manufacturing machinery are relatively easy to maintain and replace. Regular inspection and lubrication of the pulleys, along with routine belt tension checks, contribute to efficient operation and prevent unexpected breakdowns. When replacement is necessary, flat belts and pulleys are readily available, minimizing downtime and optimizing overall machine performance.

7. Cost-effectiveness:

Flat belt pulleys offer a cost-effective solution for power transmission in textile manufacturing machinery. They are relatively simple in design, require minimal maintenance, and have lower initial costs compared to alternative transmission systems. The cost-effectiveness of flat belt pulleys makes them a preferred choice in the textile industry.

Overall, flat belt pulleys play a vital role in textile manufacturing machinery by ensuring efficient power transmission, enabling speed control, maintaining belt tension and tracking, enhancing belt longevity, reducing noise and vibration, facilitating maintenance and replacement, and providing a cost-effective solution. Their proper selection, installation, and maintenance are crucial for optimal performance and productivity in textile manufacturing processes.

How does the design of a flat belt pulley affect its performance?

The design of a flat belt pulley plays a crucial role in determining its performance characteristics. Here’s a detailed explanation:

1. Groove Profile:

The groove profile of a flat belt pulley affects the grip and traction between the pulley and the belt. Different groove profiles, such as V-shaped, U-shaped, or flat, are used depending on the type of belt being used. The groove profile should be designed to optimize the belt’s contact area and prevent slippage, ensuring efficient power transmission.

2. Diameter and Width:

The diameter and width of the pulley directly impact its mechanical advantage and power transmission capabilities. Larger pulley diameters result in higher belt speeds and increased power transmission capacity, while wider pulleys provide better belt support and reduced belt stress.

3. Material Selection:

The choice of material for the pulley affects its strength, durability, and resistance to wear and corrosion. Commonly used materials include steel, cast iron, aluminum, and plastics. The material selection should be based on factors such as the load capacity, operating environment, and desired lifespan of the pulley.

4. Balance and Alignment:

A well-designed flat belt pulley should be properly balanced and aligned to minimize vibration and ensure smooth operation. Imbalances or misalignment can result in increased noise, reduced efficiency, and premature wear of the pulley and belt.

5. Tensioning Mechanism:

The design of the tensioning mechanism, such as an idler pulley or tensioning screw, can impact the ease of belt tensioning and the ability to maintain proper belt tension over time. A well-designed tensioning mechanism ensures consistent and reliable power transmission by maintaining the optimal tension in the belt.

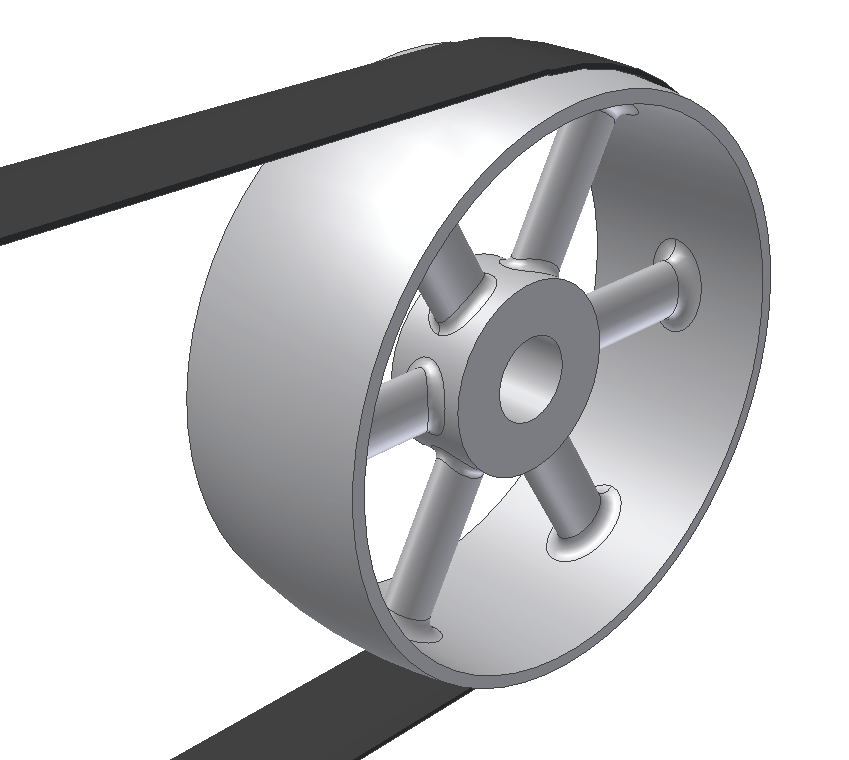

6. Flanges and Hub Configuration:

The presence of flanges or the configuration of the hub can affect the stability and alignment of the pulley. Flanges help to keep the belt contained within the pulley, preventing lateral movement and ensuring proper tracking. The hub configuration should provide a secure and accurate connection to the shaft, minimizing slippage or misalignment.

7. Surface Finish and Coating:

The surface finish and coating of the pulley can influence its friction characteristics, wear resistance, and corrosion protection. Smooth surface finishes and appropriate coatings can reduce friction, extend the life of the pulley and belt, and improve overall performance.

By carefully considering and optimizing these design factors, flat belt pulleys can be engineered to deliver efficient and reliable power transmission, minimize belt wear, and ensure long-lasting performance in various applications.

What is a flat belt pulley, and how does it function in machinery?

A flat belt pulley is a type of pulley used in machinery that utilizes a flat belt for power transmission. Here’s a detailed explanation:

1. Design and Construction:

A flat belt pulley consists of a cylindrical or disk-shaped body with a flat or slightly concave surface. It is typically made of durable materials such as cast iron, steel, or aluminum. The pulley may have one or more grooves or channels on its surface to accommodate the flat belt, ensuring proper engagement and power transfer.

2. Power Transmission:

The primary function of a flat belt pulley is to transmit power from a driving source, such as an engine or motor, to a driven component in machinery. The flat belt connects the driving pulley (also known as the driver) to the driven pulley (also known as the driven). As the driving pulley rotates, it imparts rotational motion to the flat belt, which in turn transfers the power to the driven pulley. This enables the driven component to perform its intended function.

3. Belt Grip and Traction:

A flat belt pulley provides grip and traction on the flat belt, ensuring efficient power transfer and minimizing slippage. The design of the pulley surface, including any grooves or channels, helps maintain proper belt engagement and prevents the belt from slipping or coming off the pulley during operation. The pulley’s material and surface finish are chosen to optimize friction and traction between the pulley and the belt.

4. Speed and Torque Conversion:

By varying the size of the flat belt pulleys in a machinery system, the rotational speed and torque can be converted according to the desired requirements. The ratio of the pulley diameters determines the speed ratio between the driving and driven components. For example, a larger pulley on the driving side and a smaller pulley on the driven side will result in increased speed at the driven component but reduced torque. This allows for the customization and adaptation of machinery to different operational needs.

5. Tension and Alignment:

A flat belt pulley aids in maintaining proper tension and alignment of the flat belt. Tensioning mechanisms, such as adjustable pulley positions or tensioners, are utilized to ensure optimal tension in the belt. Proper tension prevents slippage and ensures the belt remains tightly engaged with the pulleys. Additionally, flat belt pulleys may incorporate features like crowned surfaces or tracking guides to aid in belt alignment, reducing the risk of misalignment and optimizing power transmission.

6. Maintenance and Replacement:

Regular maintenance and inspection of flat belt pulleys are essential for their proper functioning. It is important to check for wear, damage, or misalignment of the pulley and the flat belt. Any worn or damaged pulleys should be replaced promptly to prevent performance issues and potential failures in the machinery.

In summary, a flat belt pulley is a key component in machinery for power transmission using flat belts. It provides grip and traction, facilitates speed and torque conversion, aids in tension and alignment, and requires regular maintenance to ensure optimal performance.

editor by CX

2024-03-05