Product Description

Aluminum Synchronous Flat Belt Pulley with Flanges

1. Description

| No. | Item | Description |

| 1 | Name | Synchronous Wheel |

| 2 | Size | Products can be customized. |

| 3 | Material | Main Cast Iron and Aluminium.etc |

| 4 | Production Process | The main process is machining center. |

| 5 | Heat Treatment | Selecting heat treatment according to the different materials. |

| 6 | Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

| 7 | Certification | GB/T19001-2016/ISO9001:2015 |

| 8 | Usage | Used in printing machine, cleaning machine, medical equipment, garden machine, construction machine, electric car, valve, forklift, transportation equipment and various gear reducers.etc |

| 9 | Package | According to customer’s request |

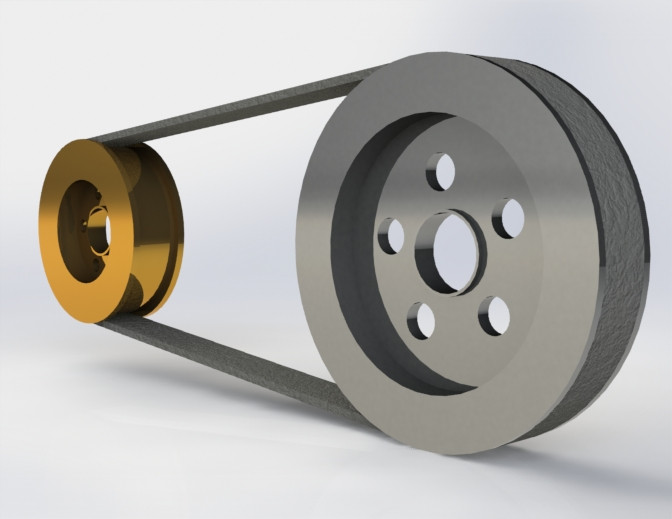

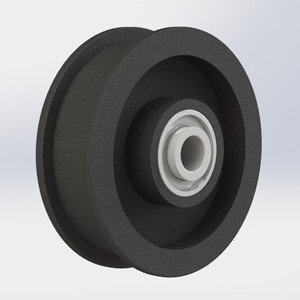

2. Photos

3.Order process

a. Customer sends us the drawing or sample, If only sample, our company supply the CAD drawing.

b. Our company supplies the processing technique and quotation.

c. Our company supplies the sample after customer confirmed processing technique and quotation.

d. Customer places the order after confirm the sample.

e. Customer pay 50% deposit

f. Quantity production.

g. Pay the balance after the acceptance and confirmation.

h. Delivery.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Type H |

| Manufacturing Process: | Forging |

| Material: | Cast Iron and Aluminium.etc |

| Surface Treatment: | Blackend |

| Application: | Chemical Industry, Power Plant |

| Samples: |

US$ 25/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do flat belt pulleys affect the performance of textile manufacturing machinery?

Flat belt pulleys have a significant impact on the performance of textile manufacturing machinery. Here’s a detailed explanation:

1. Power Transmission:

Flat belt pulleys are essential for transmitting power from the motor or engine to various components within textile manufacturing machinery. They serve as driving pulleys, connecting the power source to critical machine parts, such as spindles, rollers, and looms. The efficient power transmission facilitated by flat belt pulleys ensures the smooth operation of these components, enabling the production of high-quality textiles.

2. Speed Control:

Textile manufacturing machinery often requires precise speed control for different processes, such as spinning, weaving, or knitting. Flat belt pulleys, when used in conjunction with adjustable speed drives, allow operators to control the rotational speed of the driven components. By selecting pulleys of different sizes or adjusting the pulley positions, the speed ratios can be modified, enabling optimal machine performance and ensuring the production of textiles with consistent quality.

3. Tensioning and Tracking:

Flat belts in textile manufacturing machinery need to be properly tensioned and tracked to ensure smooth and reliable operation. Flat belt pulleys are equipped with tensioning mechanisms and tracking features to maintain the appropriate belt tension and alignment. Proper tensioning and tracking, facilitated by the pulleys, prevent belt slippage, reduce wear and tear, and minimize the occurrence of defects in textile production.

4. Belt Longevity:

Flat belt pulleys, when designed and maintained correctly, contribute to the longevity of the belts used in textile manufacturing machinery. The pulleys should have smooth surfaces and edges, minimizing friction and wear on the belts. Additionally, regular inspection and maintenance of the pulleys, including checking for proper alignment and cleaning, help prevent belt damage and extend their lifespan.

5. Noise and Vibration Reduction:

Textile manufacturing machinery often operates at high speeds, leading to noise and vibration. Properly balanced and aligned flat belt pulleys help reduce these undesirable effects by ensuring smooth and stable power transmission. Minimizing noise and vibration improves the working environment for operators and helps maintain the integrity of the textile manufacturing process.

6. Maintenance and Replacement:

Flat belt pulleys in textile manufacturing machinery are relatively easy to maintain and replace. Regular inspection and lubrication of the pulleys, along with routine belt tension checks, contribute to efficient operation and prevent unexpected breakdowns. When replacement is necessary, flat belts and pulleys are readily available, minimizing downtime and optimizing overall machine performance.

7. Cost-effectiveness:

Flat belt pulleys offer a cost-effective solution for power transmission in textile manufacturing machinery. They are relatively simple in design, require minimal maintenance, and have lower initial costs compared to alternative transmission systems. The cost-effectiveness of flat belt pulleys makes them a preferred choice in the textile industry.

Overall, flat belt pulleys play a vital role in textile manufacturing machinery by ensuring efficient power transmission, enabling speed control, maintaining belt tension and tracking, enhancing belt longevity, reducing noise and vibration, facilitating maintenance and replacement, and providing a cost-effective solution. Their proper selection, installation, and maintenance are crucial for optimal performance and productivity in textile manufacturing processes.

Can flat belt pulleys be customized for specific machinery and equipment?

Yes, flat belt pulleys can be customized to suit specific machinery and equipment requirements. Here’s a detailed explanation:

1. Pulley Dimensions:

Flat belt pulleys can be customized in terms of their dimensions to fit the specific space and clearance constraints of the machinery or equipment. The outer diameter, inner diameter, and width of the pulley can be adjusted to ensure proper alignment and fit within the system.

2. Shaft Compatibility:

Customized flat belt pulleys can be designed to match the shaft size and configuration of the machinery or equipment. This ensures a secure and accurate connection between the pulley and the shaft, minimizing any potential slippage or misalignment issues.

3. Material Selection:

The choice of material for the pulley can be customized based on the specific requirements of the machinery or equipment. Different materials, such as steel, aluminum, or plastic, offer varying levels of strength, durability, and corrosion resistance. The material selection can be tailored to suit factors such as the operating environment, load capacity, and desired longevity of the pulley.

4. Keyways and Set Screw Holes:

Customized flat belt pulleys can be manufactured with keyways or set screw holes to enhance the connection and torque transfer between the pulley and the shaft. Keyways provide a positive locking mechanism, preventing rotational slippage, while set screw holes allow for secure fastening using set screws.

5. Surface Coatings:

In certain cases, customized flat belt pulleys can be coated or treated with specific surface finishes or coatings. These coatings can provide benefits such as improved wear resistance, reduced friction, or enhanced corrosion protection, depending on the operating conditions and requirements of the machinery or equipment.

6. Special Features:

Customized flat belt pulleys can incorporate special features or modifications based on the unique needs of the machinery or equipment. This may include additional mounting holes, balancing adjustments, or specific groove profiles to accommodate different belt types or configurations.

By working with pulley manufacturers or suppliers, machinery or equipment manufacturers can collaborate to design and produce customized flat belt pulleys that precisely meet the requirements of their specific applications.

It’s important to note that the customization process will depend on factors such as the complexity of the pulley design, production feasibility, and any minimum order quantities that may be required by the manufacturer.

How do flat belt pulleys handle variations in load capacity and speed?

Flat belt pulleys are designed to handle variations in load capacity and speed in power transmission systems. Here’s a detailed explanation:

1. Load Capacity:

Flat belt pulleys can accommodate variations in load capacity by adjusting the tension in the flat belt. Increasing the tension in the belt helps to transmit higher loads, while reducing the tension allows for lower loads. The tension can be adjusted by adjusting the position of the pulleys or by using tensioning devices such as idler pulleys or tensioning screws. By properly tensioning the belt, flat belt pulleys can efficiently transmit power and handle different load capacities.

2. Speed Variation:

Flat belt pulleys can handle variations in speed by adjusting the pulley diameters. The speed ratio between the driving pulley and the driven pulley determines the speed at which power is transmitted. By using pulleys with different diameters, the rotational speed can be adjusted accordingly. For example, a larger pulley on the driving shaft and a smaller pulley on the driven shaft will result in increased speed, while a smaller driving pulley and a larger driven pulley will reduce the speed. By selecting the appropriate pulley sizes, flat belt pulleys can accommodate different speed requirements in power transmission systems.

3. Variable Speed Pulleys:

In applications where continuous speed variation is required, variable speed pulleys can be used. These pulleys, also known as stepless or variable pitch pulleys, consist of two conical pulleys that can move axially, changing the effective diameter of the pulley. By adjusting the position of the conical pulleys, the speed ratio can be continuously varied, allowing for precise control of the transmitted speed. Variable speed pulleys are commonly used in applications such as conveyors, fans, and certain types of machinery that require adjustable speeds.

4. Belt Material Selection:

The choice of belt material can also contribute to handling variations in load capacity and speed. Different belt materials possess varying levels of strength, flexibility, and wear resistance. By selecting the appropriate belt material based on the specific application requirements, flat belt pulleys can effectively handle variations in load capacity and speed. For example, high-strength materials may be chosen for heavy-duty applications, while more flexible materials may be suitable for applications with high-speed variations.

It’s important to note that while flat belt pulleys can handle variations in load capacity and speed to a certain extent, there are practical limits based on the design and capabilities of the specific pulley system. It’s crucial to consider the manufacturer’s specifications, operating conditions, and safety factors when determining the suitable load capacity and speed requirements for a flat belt pulley system.

editor by CX

2024-01-16