Product Description

OUR PARTNERS

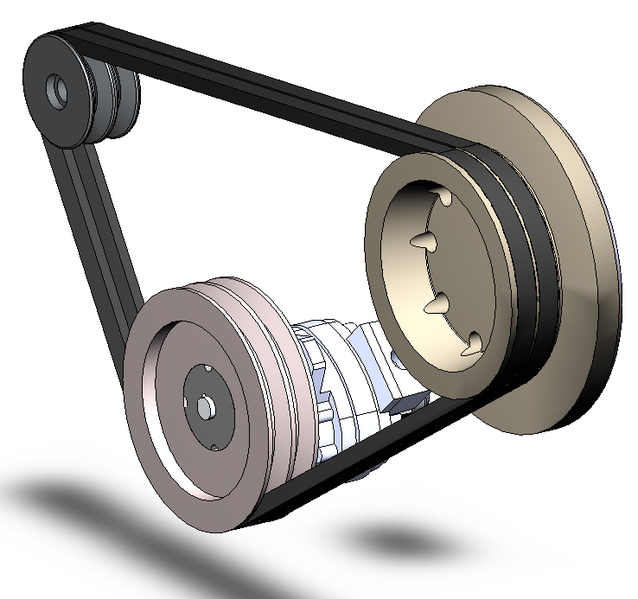

PRODUCT: Tiger Industrial Manufacturer 3.3mm Chrome Leather High Speed Power Transmission Canada Electronic Machine Diving Belts Supplier F-40D

TECHNICAL DATAS

| Type | F-40D | |

| Belt thickness | 3.3mm | |

| Color | Dark Green& Grey | |

| Surface | Rough structure | |

| Weight | 3.5kg/m2 | 0.7165 lbs./ft.2 |

| Force at 1% elongation | 10N/mm | 57.1429 lbs./in. |

| Min. pulley diameter | 40mm | 1.5748in. |

| Standard roll belt width | 500mm | 19.685in. |

| Elongation at fitting | 1.6%-2.6% | |

| Endless instructions | Hot splicing with overlap is always preferable. | |

APPLICATIONS

PAYMENT METHODS

T/T, Western Union, Moneygram are current terms.

WHY CHOOSE US

QUALITY ASSURANCE

Guarantee that the commodity hereof complies in all respects with the quality and specification stipulated in the contract.

DELIVERY GUARANTEE

Ship the goods within the shipment time from the port of shipment to the destination in the contract.

FACTORY PRICE

Prices refer to the cost of raw materials directly from factory.

TEAM OF PROFESSIONALS

Offer experienced customer service and technical support including belts selection, calculation, application and after-sale service.

FABRICATION WORKSHOP

Provide belts cutting, jointing, as well as belt perforations, belt sealed, belt coated with rubber and sponge, belt guides, etc.

SERVICE NETWORK

Set up office, branches in HangZhou, HangZhou, HangZhou, Hongkong, etc, service locations for processing industrial belts in HangZhou, HangZhou, Yongbo etc.

ABOUT US

Overview

| Quality Assurance System | Tiger Standard |

| Telephone | 86 |

| Trademark | TGRBELT |

| Managing Director | Mr. Li |

Company Introduction

Our Products

Production and Processing

Test Report

OTHER RELATED PRODUCTS

-machine tape

-spindle tape

-tangential drive belt

-OE rotor spinning belt

-twisting flat belt

-folder-gluer belt

-extruded round belt polycord

-conveyor processing belt

-open belt cutting to the sizes

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Nonstandard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Packaging Machinery, Food Machinery, Agricultural Machinery |

| Feature: | Flame-Retardant, Anti-Static, Oil-Resistant, Cold-Resistant, Corrosion-Resistant, Heat-Resistant, Alkali-Resistant, Skid-Resistance, Wear-Resistant, Acid-Resistant, High Temperature-Resistance |

| Tensile Strength: | Strong |

| Material: | Rubber |

| Type: | Flat Belt |

What is the role of flat belt pulleys in agricultural machinery and equipment?

Flat belt pulleys play a crucial role in agricultural machinery and equipment, contributing to various operations and functions. Here’s a detailed explanation:

1. Power Transmission:

Flat belt pulleys are commonly used in agricultural machinery to transmit power from an engine or motor to different components. They serve as driving pulleys, connecting the power source to various agricultural implements and equipment such as threshers, pumps, conveyors, and grain elevators. The efficient power transmission facilitated by flat belt pulleys enables the proper operation of these agricultural machines.

2. Belt-Driven Systems:

Many agricultural machines utilize belt-driven systems, where flat belts and pulleys are employed to transfer power. These systems are cost-effective, easy to maintain, and provide smooth power transmission. Flat belt pulleys are key components in these systems, ensuring reliable power transfer and facilitating the movement of materials or the operation of specific agricultural processes.

3. Threshing and Harvesting:

In agricultural machinery such as threshers, flat belt pulleys are integral to the threshing and harvesting process. They drive the rotating mechanisms that separate grain or seeds from the crop plants. The pulleys provide the necessary power to rotate the threshing drum or cylinder, facilitating the separation of grain or seeds from the harvested crop.

4. Irrigation and Water Pumps:

Flat belt pulleys are utilized in agricultural equipment for irrigation and water pumping applications. They drive water pumps that draw water from wells, rivers, or other sources and distribute it for irrigation purposes. The pulleys transmit power from the engine or motor to the pump, enabling efficient water pumping and irrigation operations in agricultural fields.

5. Conveyor Systems:

Agricultural conveyor systems, used for tasks such as transporting crops, seeds, or harvested produce, often incorporate flat belt pulleys. The pulleys drive the conveyor belts, facilitating the movement of agricultural materials within the farm or processing facility. These conveyor systems are crucial for efficient material handling and sorting in agricultural operations.

6. Equipment Adjustability:

Flat belt pulleys offer adjustability in agricultural machinery and equipment. By using pulleys of different sizes or adjusting the pulley positions, the speed ratios and power transmission characteristics can be modified. This adjustability allows farmers and operators to optimize the performance of agricultural machines based on specific requirements, crop conditions, or operational preferences.

7. Versatility and Durability:

Agricultural environments can be demanding, with exposure to dust, moisture, and other challenging conditions. Flat belt pulleys are designed to be versatile and durable, capable of withstanding the rigors of agricultural applications. They are often constructed from materials such as cast iron or steel, ensuring longevity and reliable performance even in harsh agricultural settings.

Overall, flat belt pulleys play a vital role in agricultural machinery and equipment by facilitating efficient power transmission, driving essential components and processes, enabling adjustability, and ensuring the smooth operation of various agricultural operations.

What types of materials are commonly used for flat belt pulley components?

Flat belt pulleys are typically composed of various materials for different components to meet specific requirements. Here’s a detailed explanation:

1. Pulley Body:

The main body of a flat belt pulley is commonly made of durable and rigid materials such as:

- Steel: Steel pulleys offer excellent strength, durability, and resistance to wear. They are commonly used in heavy-duty applications where high load capacities and long service life are required.

- Cast Iron: Cast iron pulleys are known for their high strength and resistance to wear. They are often used in industrial applications where durability and reliability are essential.

- Aluminum: Aluminum pulleys are lightweight and have good corrosion resistance. They are commonly used in applications where weight reduction is a priority or in environments where corrosion is a concern.

- Plastics: Certain types of plastics, such as nylon or polyurethane, are used in pulleys where low weight, noise reduction, or chemical resistance is required. Plastic pulleys are often used in applications that involve delicate or sensitive machinery.

2. Hub:

The hub of a flat belt pulley, which connects the pulley to the shaft, is typically made of:

- Steel: Steel hubs offer high strength and reliable connection to the shaft. They are commonly used in heavy-duty applications.

- Aluminum: Aluminum hubs are lightweight and provide good corrosion resistance. They are often used in applications where weight reduction is important.

3. Surface Coating:

To enhance the performance and durability of flat belt pulleys, surface coatings or treatments may be applied. Some common coatings include:

- Zinc or Nickel Plating: These coatings provide corrosion resistance and improve the pulley’s appearance.

- Anodizing: Anodized coatings on aluminum pulleys increase their resistance to wear and corrosion.

- Powder Coating: Powder coating provides a durable and protective layer on the pulley surface, offering improved aesthetics and resistance to corrosion, chemicals, and abrasion.

It’s important to select the appropriate materials for flat belt pulleys based on factors such as the application’s load requirements, environmental conditions, desired lifespan, and cost considerations. Consulting with pulley manufacturers or suppliers can help in determining the most suitable materials for specific pulley components.

Can you explain the typical applications of flat belt pulleys in machinery?

Flat belt pulleys are utilized in various machinery applications where power transmission using flat belts is required. Here’s a detailed explanation of their typical applications:

1. Industrial Machinery:

Flat belt pulleys find extensive use in industrial machinery across different sectors. They are commonly employed in machinery such as conveyor systems, manufacturing equipment, packaging machines, textile machinery, and woodworking machinery. These pulleys enable power transmission to drive various components, such as rollers, gears, cutting tools, and conveyor belts, facilitating the processing, movement, and manipulation of materials in industrial processes.

2. Agricultural Equipment:

In the agricultural sector, flat belt pulleys are used in machinery like threshers, combines, grain elevators, and hay balers. They play a crucial role in powering components such as fans, augers, pumps, and feeders. Flat belt pulleys provide a cost-effective and reliable solution for power transmission in agricultural equipment, allowing for efficient crop processing, harvesting, and handling operations.

3. Vintage Machinery:

Flat belt pulleys have historical significance and are often associated with vintage machinery. Before the widespread adoption of modern power transmission systems, such as V-belts or chains, flat belts and flat belt pulleys were commonly used. Therefore, flat belt pulleys can be found in antique or vintage machinery, including old lathes, milling machines, printing presses, and other early industrial equipment.

4. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems utilize flat belt pulleys in certain applications. These pulleys are used to transmit power to components like fans, blowers, and pumps in HVAC units. They help in ensuring efficient air circulation, temperature control, and fluid movement within HVAC systems, contributing to the overall performance and functionality of the systems.

5. Exercise Equipment:

Flat belt pulleys are also employed in exercise equipment such as treadmills, rowing machines, and stationary bikes. These pulleys assist in transferring power from the motor to the various moving parts of the exercise equipment, allowing for smooth and controlled movements during workouts.

6. Garage Door Openers:

Flat belt pulleys are used in garage door opener systems to transmit power from the motor to the pulley on the garage door shaft. The rotational motion of the pulley is transferred to the door’s lifting mechanism, enabling the smooth and automatic opening and closing of garage doors.

7. Other Applications:

Flat belt pulleys can be found in a range of other applications, including printing machines, paper mills, sewing machines, power tools, and various mechanical systems that require power transmission using flat belts.

It’s important to note that with advancements in technology, other types of power transmission systems, such as V-belts, timing belts, or direct drives, have gained popularity in many applications. However, flat belt pulleys continue to be used in specific machinery and industries where they offer advantages such as simplicity, cost-effectiveness, and compatibility with existing equipment.

editor by CX

2024-02-06