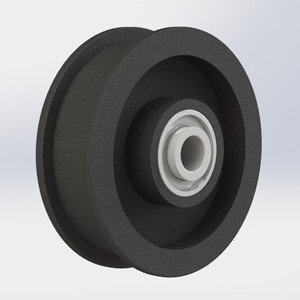

Product Description

Product Description

Product Parameters

| Parameter of conveyor drum pulley | |||

| Type | Belt width | Standard diameter | Length(mm) |

| (mm) | (mm) | ||

| Length of pulley depends on the width of conveyor belt | 500 | 500 | Length of pulley

depends on the width of conveyor belt |

| 650 | 500~630 | ||

| 800 | 630~1000 | ||

| 1000 | 800~1150 | ||

| 1200 | 800~1150 | ||

| 1400 | 1000~1350 | ||

| 1600 | 1150~1600 | ||

| 1800 | 1150~1800 | ||

| 2000 | 1350~2000 | ||

| 2200 | 1600~2200 | ||

| 2400 | 1800~2400 | ||

Production Workshop

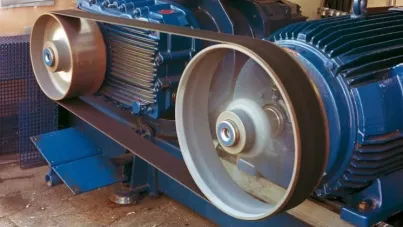

Application scenario

Our Advantages

FAQ

Q1. When can I get the price?

Usually we quote within 24 hours after we get your inquiry.

Q2: Could design and drawing the pulley for our special usage?

A: Of course, our professional engineer could design and drawing for you ASAP.

Q3:How to install the Ceramic Pulley Lagging?

A:We have experience of installation for 20 years, and could supply guidance for you by video.

Q4: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q5: Do you have foreign experience for Ceramic Pulley Lagging rubber sheet?

A: Yes, the ceramic lagging rubber sheet we manufactured have exported to Australia , South Africa , Brazil , etc.

Q6. How does your factory of regarding quality control?

A: To make sure customer buy good quality material and service from us. Before customer place order, we will send drawing to customer for approval. Before shipment, our QC staff will check quality 1pc by 1pc. Quality is our culture. /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Stainless Steel |

|---|---|

| Surface Treatment: | Baking Paint |

| Motor Type: | Frequency Control Motor |

| Samples: |

US$ 70/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can flat belt pulleys be part of woodworking and milling equipment?

Yes, flat belt pulleys can be an integral part of woodworking and milling equipment. Here’s a detailed explanation:

1. Power Transmission:

Flat belt pulleys are commonly used in woodworking and milling equipment to transmit power from a motor or engine to various components. They serve as driving pulleys, connecting the power source to critical machine parts such as saw blades, cutters, drills, or spindles. The efficient power transmission facilitated by flat belt pulleys ensures the smooth and precise operation of these components, enabling accurate woodworking and milling processes.

2. Speed Control:

Woodworking and milling equipment often require adjustable speed control for different tasks and materials. Flat belt pulleys, in combination with adjustable speed drives, allow operators to control the rotational speed of the driven components. By selecting pulleys of different sizes or adjusting the pulley positions, the speed ratios can be modified to match specific cutting or milling requirements, ensuring optimal machine performance and quality of the finished products.

3. Load Capacity:

Woodworking and milling equipment handle various types and sizes of materials, which may exert different loads on the machines. Flat belt pulleys are designed to handle different load capacities based on the specific requirements of the equipment. The pulley’s diameter and width are chosen to provide adequate support and load-bearing capacity for the belt, enabling the machines to handle different workpieces effectively.

4. Belt Tensioning and Tracking:

Proper belt tensioning and tracking are crucial in woodworking and milling equipment to ensure accurate cuts and milling operations. Flat belt pulleys are equipped with tensioning mechanisms and tracking features to maintain the appropriate belt tension and alignment. This helps prevent belt slippage, ensures precise movement of the workpiece, and minimizes the occurrence of errors or defects in the woodworking and milling processes.

5. Versatility:

Flat belt pulleys offer versatility in woodworking and milling equipment design. They can be used in various types of machines, such as table saws, band saws, planers, routers, and milling machines. The flexibility of flat belts also enables efficient movement around pulleys of different sizes and configurations, catering to the specific needs of different woodworking and milling tasks.

6. Durability and Precision:

Woodworking and milling equipment require pulleys that are durable and capable of providing precise power transmission. Flat belt pulleys are often constructed from materials such as cast iron or steel, ensuring strength and longevity. The precision of the pulley design, including accurate machining and balance, contributes to the overall precision of the woodworking and milling processes.

7. Maintenance and Replacement:

Flat belt pulleys in woodworking and milling equipment are relatively easy to maintain and replace. Regular inspection and lubrication of the pulleys, along with routine belt tension checks, contribute to efficient operation and prevent unexpected breakdowns. When replacement is necessary, flat belts and pulleys are readily available, minimizing downtime and ensuring uninterrupted woodworking and milling operations.

In summary, flat belt pulleys are commonly incorporated into woodworking and milling equipment to facilitate efficient power transmission, enable speed control, handle varying load capacities, ensure belt tensioning and tracking, offer versatility, provide durability and precision, and allow for easy maintenance and replacement. Their proper selection and maintenance are crucial for achieving high-quality woodworking and milling results.

Can flat belt pulleys be customized for specific machinery and equipment?

Yes, flat belt pulleys can be customized to suit specific machinery and equipment requirements. Here’s a detailed explanation:

1. Pulley Dimensions:

Flat belt pulleys can be customized in terms of their dimensions to fit the specific space and clearance constraints of the machinery or equipment. The outer diameter, inner diameter, and width of the pulley can be adjusted to ensure proper alignment and fit within the system.

2. Shaft Compatibility:

Customized flat belt pulleys can be designed to match the shaft size and configuration of the machinery or equipment. This ensures a secure and accurate connection between the pulley and the shaft, minimizing any potential slippage or misalignment issues.

3. Material Selection:

The choice of material for the pulley can be customized based on the specific requirements of the machinery or equipment. Different materials, such as steel, aluminum, or plastic, offer varying levels of strength, durability, and corrosion resistance. The material selection can be tailored to suit factors such as the operating environment, load capacity, and desired longevity of the pulley.

4. Keyways and Set Screw Holes:

Customized flat belt pulleys can be manufactured with keyways or set screw holes to enhance the connection and torque transfer between the pulley and the shaft. Keyways provide a positive locking mechanism, preventing rotational slippage, while set screw holes allow for secure fastening using set screws.

5. Surface Coatings:

In certain cases, customized flat belt pulleys can be coated or treated with specific surface finishes or coatings. These coatings can provide benefits such as improved wear resistance, reduced friction, or enhanced corrosion protection, depending on the operating conditions and requirements of the machinery or equipment.

6. Special Features:

Customized flat belt pulleys can incorporate special features or modifications based on the unique needs of the machinery or equipment. This may include additional mounting holes, balancing adjustments, or specific groove profiles to accommodate different belt types or configurations.

By working with pulley manufacturers or suppliers, machinery or equipment manufacturers can collaborate to design and produce customized flat belt pulleys that precisely meet the requirements of their specific applications.

It’s important to note that the customization process will depend on factors such as the complexity of the pulley design, production feasibility, and any minimum order quantities that may be required by the manufacturer.

How do flat belt pulleys handle variations in load capacity and speed?

Flat belt pulleys are designed to handle variations in load capacity and speed in power transmission systems. Here’s a detailed explanation:

1. Load Capacity:

Flat belt pulleys can accommodate variations in load capacity by adjusting the tension in the flat belt. Increasing the tension in the belt helps to transmit higher loads, while reducing the tension allows for lower loads. The tension can be adjusted by adjusting the position of the pulleys or by using tensioning devices such as idler pulleys or tensioning screws. By properly tensioning the belt, flat belt pulleys can efficiently transmit power and handle different load capacities.

2. Speed Variation:

Flat belt pulleys can handle variations in speed by adjusting the pulley diameters. The speed ratio between the driving pulley and the driven pulley determines the speed at which power is transmitted. By using pulleys with different diameters, the rotational speed can be adjusted accordingly. For example, a larger pulley on the driving shaft and a smaller pulley on the driven shaft will result in increased speed, while a smaller driving pulley and a larger driven pulley will reduce the speed. By selecting the appropriate pulley sizes, flat belt pulleys can accommodate different speed requirements in power transmission systems.

3. Variable Speed Pulleys:

In applications where continuous speed variation is required, variable speed pulleys can be used. These pulleys, also known as stepless or variable pitch pulleys, consist of two conical pulleys that can move axially, changing the effective diameter of the pulley. By adjusting the position of the conical pulleys, the speed ratio can be continuously varied, allowing for precise control of the transmitted speed. Variable speed pulleys are commonly used in applications such as conveyors, fans, and certain types of machinery that require adjustable speeds.

4. Belt Material Selection:

The choice of belt material can also contribute to handling variations in load capacity and speed. Different belt materials possess varying levels of strength, flexibility, and wear resistance. By selecting the appropriate belt material based on the specific application requirements, flat belt pulleys can effectively handle variations in load capacity and speed. For example, high-strength materials may be chosen for heavy-duty applications, while more flexible materials may be suitable for applications with high-speed variations.

It’s important to note that while flat belt pulleys can handle variations in load capacity and speed to a certain extent, there are practical limits based on the design and capabilities of the specific pulley system. It’s crucial to consider the manufacturer’s specifications, operating conditions, and safety factors when determining the suitable load capacity and speed requirements for a flat belt pulley system.

editor by CX

2023-12-22